Exploring the K 12 Saw: An Essential Tool for Professionals

The K 12 saw is a cutting-edge tool designed for durability and precision in various applications. Whether you are a contractor, a landscaper, or involved in emergency services, this versatile saw provides unmatched performance. Characterized by its unique design and innovative features, it has become a staple in the toolkit of professionals. In this description, we dive deep into the types, function, and applications of the K 12 saw, allowing you to understand why it's an indispensable asset in any working environment.

Types of K 12 Saws: Diverse Options for Every Task

The K 12 saw comes in various models, each tailored for specific tasks and materials. Understanding the types available can help you choose the best option for your needs.

- Gas-Powered K 12 Saws: These models are robust and designed for heavy-duty cutting tasks. They are ideal for outdoor jobs, where mobility is essential.

- Electric K 12 Saws: Portable and easier to handle, electric K 12 saws are perfect for indoor work and smaller projects that don’t require the power of gas models.

- Diamond Blade K 12 Saws: Equipped with diamond blades, these saws cut through concrete, asphalt, and bricks seamlessly, making them ideal for construction and demolition tasks.

- Multi-Function K 12 Saws: Some models incorporate multi-function capabilities, allowing users to switch between various applications without changing tools.

Function and Features of K 12 Saws: Why They Stand Out

The K 12 saw combines advanced technology with user-friendly features to offer unparalleled functionality. Here are some key aspects:

- Powerful Engine: K 12 saws typically feature robust engines that ensure fast cutting speeds without sacrificing control or precision.

- Adjustable Depth Settings: Many models allow users to adjust the cutting depth, making it easy to tackle different materials and thicknesses.

- Ergonomic Design: Designed for comfort during prolonged use, the saws come with cushioned grips and lightweight bodies, reducing fatigue.

- Enhanced Safety Features: K 12 saws include built-in safety mechanisms to prevent accidents, including blade guards and automatic shut-off systems.

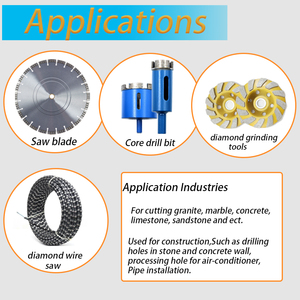

Applications of K 12 Saws: Where Can You Use Them?

The versatility of the K 12 saw means it can be applied in a variety of professional environments. Here are some primary applications:

- Construction Sites: Used for cutting concrete, stone, and metal, ideal for creating openings or prepping materials for building.

- Emergency Services: First responders frequently use K 12 saws to access trapped individuals during rescue operations or to clear debris post-emergency situations.

- Landscaping: Ideal for cutting through thick roots and pavement, making landscaping projects easier and more efficient.

- Renovation Projects: When renovating buildings, K 12 saws facilitate precise cuts into walls, floors, and other structures.

In summary, the K 12 saw is an essential tool across multiple industries, combining power, precision, and safety features that make it suitable for various applications. Whether you're a seasoned professional or a DIY enthusiast, investing in a K 12 saw can enhance your productivity and ensure high-quality results.