Types of Kama Diesel Engines

Every vehicle needs a strong, reliable machine to move it forward, which is the main feature of the Kama diesel engine models. Some of the most well-known types of diesel engines are as follows:

- 4-Stroke Diesel Engine: The four-stroke diesel engine is a type of internal combustion engine that works in four distinct stages or strokes of the piston: intake, compression, power, and exhaust. This engine is commonly utilized in the Kama 192F diesel engine model, which is famous for its efficiency and practicality.

- 2-Stroke Diesel Engine: In contrast to the 4-stroke diesel engine, the 2-stroke diesel engine completes the power cycle in just two strokes of the piston, thus generating more power than 4-stroke engines. Despite their power advantages, 2-stroke diesel engines are less common due to some drawbacks, such as higher fuel consumption and the leakage of unburned fuels into the exhaust.

- Supercharged Diesel Engine: To increase the power output and efficiency of the Kama diesel generator engine, the manufacturer may insert a supercharger. A supercharger is a mechanical device that boosts the amount of air sent into the engine by compressing it. By compressing more air into the cylinders, superchargers improve fuel combustion, resulting in more power and torque production.

- Straight Diesel Engines: Normally, diesel engines use fuel injectors to ensure complete burning. Some simple diesel engines, known as straight diesel engines, use injectors for fuel spraying. Injection methods generally fall into two main categories: direct and indirect injection.

Specifications & Maintenance

Maintaining the health of the diesel engine is no small task, but it is necessary to ensure it runs well and has a long lifespan. Many parts need to be maintained regularly, with some tasks being very frequent, like changing the fuel filter every month.

The critical parts of a diesel bike engine that need maintenance are:

- Regular oil and filter changes: It is necessary to change the oil and the diesel engine oil filter regularly. This helps remove any contaminants that could damage the engine and keep it properly lubricated. Typically, the oil needs to be changed every 500-1000 km, but it is best to check the owner’s manual to be certain.

- Cooling system: This includes the radiator and the coolant. Radiators cool diesel engines, especially in bikes, as they can become hot during use. Coolants absorb the heat and cool the engine. Radiators and coolants should be checked regularly to ensure they are not leaking, cracked, or damaged.

- Fuel filter: It ensures the fuel is free of contaminants and helps the pump do its job seamlessly. The fuel filter needs to be replaced every month or as instructed in the vehicle’s manual.

- The injector: This ensures that diesel is injected smoothly into the engine. Diesel bike engines have many fuel injectors based on the type and model. Fuel injectors need to be cleaned every few months or so. Owners can do this independently or take the bike to a professional who will thoroughly clean and de-carbonize the system. If diesel fuel injectors aren't pristine, they can affect engine performance and fuel economy. They may also cause the engine to generate excessive smoke.

- The air filter: This prevents dirt and other contaminants from entering the diesel engine. It needs to be checked every month and cleaned whenever necessary. Some air filters may need to be replaced, while others can be cleaned up pretty well.

- Gaskets and Glow Plugs: The gaskets join two engine components and need to be inspected for any damages. Glow plugs improve ignition in cold weather and should be inspected for rust or corrosion.

- Drive Belt: This transfers power from the engine to the wheels. It should be inspected for breaks and damaged areas and lubricated whenever required.

Kama Diesel Engine Application Scenarios

Kama diesel engines are designed to meet diverse industrial application needs where high loading capacity and high output are essential requirements.

-

Powering Heavy-Duty Equipment:

They are the core driving force behind many pieces of construction machinery. Therefore, they serve as the primary power source for such larger and demanding equipment as excavators, loaders, bulldozers, and road paving machines. Because of the diesel engine's high torque, it can maintain stable operational control even under heavy working conditions. Regarding advantages such as long lifespan and reliability, the machinery can work continuously even for extended periods.

-

Generators:

Kama's diesel engines serve as the power source for many types of generator sets. Their high output, fuel efficiency, and reliability will ensure the generator's stable operation. Whether used as the generator's main engine or as the generator's backup power source, it provides the generator with a continuous and reliable power supply.

-

Agricultural Machinery:

Diesel engines are commonly used in tractors and harvesters, prime movers of agricultural machinery as well. Supporting the operation and functioning of various work links such as farmland cultivation, planting, and harvesting, they help improve the efficiency and productivity of agricultural operations.

-

Maritime Vessels:

Whether small cargo ships, fishing vessels, or large container ships, diesel engines often are the preferred choice due to their high power, fuel efficiency, and reliability. They provide the ships with the main driving power, ensuring smooth maneuvering and operation of various ship functions, from navigation to cargo handling.

-

Automotive Industry:

The Kama diesel engine plays a crucial and primary role as the driving force behind heavy-duty trucks and special vehicles. Special vehicles refer to automobiles used for specific industry fields or purposes, such as fire trucks, refrigerated trucks, buses, etc. Heavy-duty trucks usually refer to cargo transportation means with a larger carrying capacity, such as road freight trucks. Their high torque output makes them especially suitable for heavy loads and long-distance transportation. Their sturdy construction also ensures that they can withstand long-term and high-intensity use.

-

Mining and Oil Extraction:

Diesel engines are the main driving force behind equipment used in mining and oil extraction. They support the operation of drilling machines, haulers, and pumps, providing the heavy torque and high power requirements needed to cope with complicated and harsh working conditions.

How to choose kama diesel engines

Selecting the appropriate kama diesel generator requires thorough consideration of usage demands and functional requirements. Here's a helpful guide for making an informed choice.

- Purpose: The main function of the kama diesel generator is to provide a backup power supply. Therefore, it is most important to ensure that the generator set can provide adequate power output for the load.

- Power: Calculate the power requirements of the user by considering factors such as the power rating of the equipment to be used, the number of appliances, and the use environment. After that, choose a kama diesel generator that has a power output greater than the calculated value. This will ensure that it can fully support the user's load demands during use.

- Engine: The engine is the core component of the kama diesel generator set, which provides the power source. When selecting a generator, users should pay attention to the brand and quality of the engine. The choice of engine should be based on the user's use needs and the working environment. For example, in a relatively quiet environment, users may need to consider choosing a low-noise engine.

- Control system: The control system of a kama diesel generator set is the part that the user interacts with for operation and monitoring during use. Users should choose a generator with an easy-to-use and reliable control system. During the selection process, users could check whether the control panel is complete and user-friendly, or whether the monitoring functions such as fault alarms and remote monitoring are available.

Q&A

Q1: What is the difference between a diesel engine and petrol in a car?

A1: Diesel engines feature a more robust build, providing durability since diesel fuel burns slower than petrol. Additionally, the compression ratio in diesel engines is significantly higher compared to petrol engines, resulting in greater torque output.

Q2: How long does a diesel engine last?

A2: Diesel engines generally have a lifespan of approximately 25-30 years, provided they are well-maintained.

Q3: Why do people prefer diesel engines?

A3: Diesel engines are known for their longevity and remarkable durability. Additionally, diesel engines produce more torque compared to petrol engines, making them ideal for heavy-duty vehicles and farming equipment that require high power levels.

Q4: What are the main parts of a diesel engine?

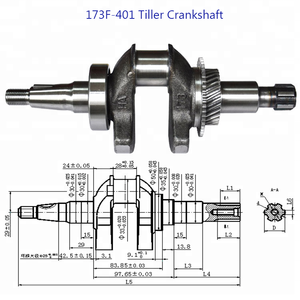

A4: A diesel engine comprises several key components, including the cylinder block, cylinder head, piston, crankshaft, injection pump, and turbocharger.