(2608 products available)

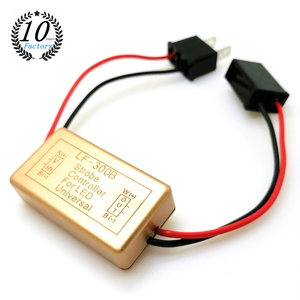

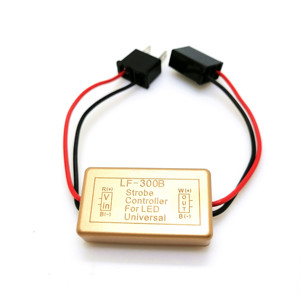

The LED flasher 12V is a small electronic component used in vehicles that have LED lighting installed. The flasher provides control of the LED lights in a pattern that flashes or blinks on and off. The LED flasher is mainly used for turn signal lights on the front, rear, and sides of the vehicle. This is an essential safety feature that alerts other drivers of the vehicle's intention to change lanes or turn. The most common type of flasher is the 2-pin and 3-pin flasher, which is interchangeable in most vehicles. The 12 volt flasher for led lights relay is an electronic component that is designed with a microcontroller, which gives it the ability to control the flashing pattern and timing of the LED lights. Flasher led 12v are available in various designs that offer different flashing patterns and features.

12v flasher have different specifications depending on the manufacturer. Here are some common ones:

Some 12 volt led flasher modules may have adjustable flash rates and timing. The flash rate can usually be set to a range, such as 60-120 flashes per minute (fpm), while the flash timing can often be adjusted between 50-200 milliseconds (ms). This allows users to customize the flashing pattern to their specific preference or application requirements.

When the 12v flasher relay is incorrectly used, it may lead to several problems. Some of the problems it may cause include hyper-flashing, where the turn signals flash at a much faster rate than normal; no flashing at all, where the turn signals remain steady and do not flash; or only one side flashing, where the turn signals on one side of the vehicle flash, but the other side does not.

Therefore, it is essential to use a properly rated 12V flasher relay that matches the vehicle's lighting system and to follow the manufacturer's instructions for installation carefully.

LED flasher 12V does not require a lot of maintenance. Ensure that the 12 volt flasher for led lights is compatible with the existing lighting system. If there are any issues, discontinue its use and consult an electrician. It is also essential to periodically inspect the flasher module and its connections for any sign of wear, damage, or corrosion. Clean the electrical contacts and terminals, if necessary, to ensure a secure connection and reliable operation. It is also crucial to avoid overloading the flasher module by exceeding its specified load capacity. In case additional lights are required, use a separate flasher module or upgrade to one with a higher load capacity to prevent potential overheating or premature failure. Following the above-given instructions will ensure the optimal performance of the LED flasher 12V and extend its lifespan.

When selecting an LED flasher, buyers should consider the following:

For the LED flasher to work effectively, it should be compatible with the turn signal lights. The compatibility allows the flasher to control the timing of the turn signals and prevent hyper-flashing.

The flasher has a load capacity that specifies the maximum current it can handle. Business buyers should select a flasher with a load capacity higher than the total current drawn by the turn signal lights. This ensures that the flasher will operate without overheating.

12 volt led flasher have different flash rates, which determine how fast the turn signal lights will flash. To maintain the original purpose of the turn signal, buyers should select a flasher with a flash rate that matches the vehicle's specification.

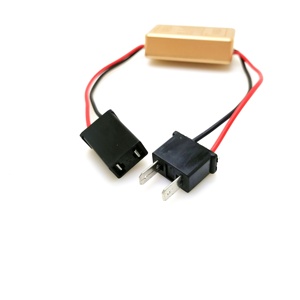

LED flashers come with different numbers of pins that connect to the vehicle's wiring harness. The business buyers should ensure that the flasher they select has the same number of pins as the vehicle's socket. This will make the installation process simple and quick.

Adjustability: Some flashers have adjustable settings that allow the user to customize the flash pattern and timing of the turn signal lights. For maximum adjustability, buyers should select a flasher with this feature.

Business buyers should select an LED flasher from reputable manufacturers. This ensures the quality and reliability of the flasher. Furthermore, they can read reviews from other users to understand the flasher's performance.

This includes the following:

This prevents any electrical shorts while working on the vehicle.

Refer to the vehicle’s manual to find the exact location of the flasher relay.

Use the socket wrench set to loosen and remove the relay from its socket.

Insert the new LED flasher relay into the socket and secure it with the socket wrench set.

After ensuring the new relay is securely installed, reconnect the battery to test the blinker operation.

If the flash rate is correct and the blinkers are working well, the DIYer has successfully replaced the LED flasher 12v. Otherwise, they should recheck the connections or consult a professional in case of any arising issues.

Ensure proper disposal according to local regulations.

Q1: How can LED flasher 12V be tested?

A1: When testing an LED flasher, ensure the power is off. The positive and negative wires should be connected to the input side of the flasher. The red wire is connected to the L+ terminal, and the black wire is connected to the L- terminal. Then, take a 12-volt test light and touch the probe to the P terminal. The light should not turn on at this point. If the light turns on at this point, the flasher is defective.

Q2: What is the purpose of an LED flasher?

A2: An LED flasher is used to control the blinking speed of LED bulbs. It is commonly used when converting turn signals to LED. The flasher will blink at a normal rate for a standard bulb. This allows the turn signal flasher to work properly so the LED bulbs will flash as well.

Q3: How long do LED flashers last?

A3: LED flashers are designed to last for a long time. They have a lifespan of up to 100,000 hours. This is much longer than traditional incandescent light bulbs, which only last for about 1,000 hours.