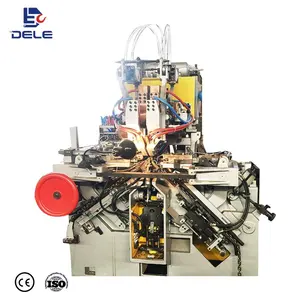

Introduction to Link Chain Bending Welding Machine

The link chain bending welding machine is an indispensable tool for the fabrication and assembly of link chains used across various industries. This high-performance machine combines precision bending and robust welding capabilities, enhancing productivity and ensuring high-quality output. From manufacturing lifting equipment to agricultural tools, the versatility of this machine plays a pivotal role in creating durable link chains that can withstand heavy-duty applications.

Types of Link Chain Bending Welding Machines

Understanding the different types of link chain bending welding machines can help industries select the right tool for their specific needs.

- Manual Link Chain Bending Welding Machine

- Designed for smaller production lines or workshops.

- Operated manually, providing flexibility for custom jobs.

- Semi-Automatic Link Chain Bending Welding Machine

- Combines manual control with automated features.

- Ideal for mid-scale production tasks.

- Fully Automatic Link Chain Bending Welding Machine

- Engineered for high-volume production.

- Features sophisticated programming for enhanced efficiency.

Function and Feature of Link Chain Bending Welding Machine

The efficiency of a link chain bending welding machine lies in its well-designed functions and innovative features.

- Precision Bending and Welding:

- Advanced technology ensures accurate angles and weld quality.

- Ability to adjust bending radii for various link sizes.

- Durable Construction:

- Built using high-grade steel and components for longevity.

- Built-in safety features reduce the risk of operation errors.

- User-Friendly Interface:

- Equipped with intuitive controls for ease of operation.

- Clear display for monitoring machine performance and diagnostics.

Applications of Link Chain Bending Welding Machine

The link chain bending welding machine finds extensive application across various sectors, proving its utility in countless scenarios.

- Construction Industry:

- Manufacturing heavy-duty chains used in cranes and hoists.

- Production of safety chain assemblies for construction sites.

- Agriculture:

- Creating chain systems for lifting and securing equipment.

- Utilized in manufacturing agricultural machinery components.

- Manufacturing:

- Crafting chains for conveyor systems and material handling.

- Production of specialized chains for automotive applications.