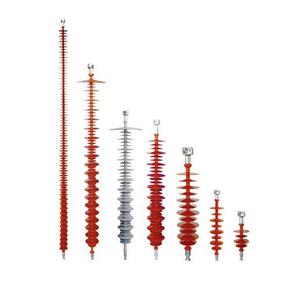

Understanding Long Rod Composite Insulators

Long rod composite insulators are crucial components in the power transmission and distribution industry, designed to endure harsh environments while maintaining electrical integrity. These insulators stand out because of their impressive mechanical strength, lightweight design, and resistance to environmental stressors. With rapid advancements in materials and manufacturing processes, long rod composite insulators are becoming the preferred choice for utilities around the world.

Types of Long Rod Composite Insulators

- High Voltage Insulators: Designed for applications in high voltage environments, these insulators can handle voltages exceeding 100 kV, ensuring reliability and safety.

- Medium Voltage Insulators: Ideal for medium voltage power systems, these insulators typically range between 1 kV to 35 kV, providing excellent performance for local distribution lines.

- Specialty Insulators: These insulators cater to specific industrial needs, including those used in areas with high pollution or extreme weather conditions.

- Customized Insulators: Tailored to meet unique project specifications, ensuring the best fit for specific applications and conditions.

Features and Applications of Long Rod Composite Insulators

- Lightweight Design: The lightweight nature of composite materials reduces installation costs and simplifies handling. This characteristic allows for less structural support and easier integration.

- High Mechanical Strength: These insulators can withstand significant mechanical loads, making them ideal for installations in challenging environments, including areas prone to high winds and seismic activity.

- Corrosion Resistance: Made from advanced materials that resist UV degradation, pollution, and corrosion, ensuring longevity and reducing maintenance costs.

- Applications:

- Used in overhead power lines

- Substations and switching stations

- Railways and tram systems

- Wind and solar power installations

Advantages of Long Rod Composite Insulators

- Enhanced Durability: The long lifespan of these insulators, typically exceeding 30 years, ensures reliability and reduces the frequency of replacements.

- Improved Performance: Their superior dielectric properties enhance the efficiency of electrical transmission, lowering energy loss.

- Environmental Versatility: Capable of operating in a wide range of climatic conditions, including high humidity, extreme temperatures, and high pollution areas.

- Cost-Effective: Although the initial investment may be higher than traditional materials, the reduced maintenance and replacement costs yield significant long-term savings.

How to Choose the Right Long Rod Composite Insulator

- Assess Voltage Ratings: Understanding the specific voltage requirements of your application is crucial in selecting the appropriate insulator.

- Consider Environmental Conditions: Evaluate the environmental factors such as pollution level, temperature variations, and mechanical stress.

- Analyze Mechanical Load: Determine the mechanical loads the insulator will be subject to, including wind load and dynamic forces from power lines.

- Check Compliance Standards: Ensure that the insulators meet applicable industry standards for quality and safety to guarantee performance and reliability.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4