(68661 products available)

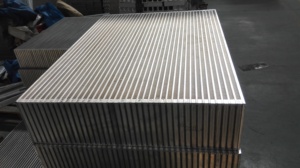

A heat exchanger machine is designed to transfer heat between two or more fluids effectively. There are two broad types based on the flow arrangement: counterflow heat exchanger machine and parallel flow heat exchanger machine.

The other categorization of a heat exchanger machine is based on the design:

The specifications of an industrial heat exchanger machine will vary depending on the type and application. Factors such as material, size, efficiency, pressure, and temperature can influence the specification of heat exchangers.

It is crucial to maintain industrial heat exchanger machines regularly to ensure they operate efficiently. Inefficient machines can drive up energy costs because they use more energy to compensate for the loss. Regular maintenance can also prolong the machine's life. Here are some maintenance tips to keep in mind:

Heat exchangers are used in many industries to facilitate efficient heat transfer. Here are some of the machine heat exchanger usages.

Food processing

Industry stainless cooling and heating machines are commonly applied in food processing. They heat food products like milk to kill bacteria and improve the shelf life. Besides, they link heat recovery systems to reuse waste heat to lower the energy cost in the industry.

Energy production

Industries machine heat exchangers are vital in power plants. They generate steam by transferring heat from burning fossil fuels or biomass. In addition, they are linked to condensers that cool and condense steam into water to reuse it in the boiling process. Waste heat exchangers recover heat from diesel generators and combustion engines to preheat incoming fuel or air, improving the efficiency of combustion systems and ensuring optimal performance.

Chemical manufacturing

Cooling and heating machines are also found in chemical manufacturing. They are used in reactors and boilers to control chemical reactions and produce chemicals. Besides, they are used to cool down reaction mixtures to prevent overheating and avoid undesired chemical reactions.

HVAC

Heat exchangers are the core component in HVAC systems. They are used in air conditioners, chillers, and refrigeration machines to cool down and remove heat from buildings. Besides, they allow heat recovery from exhaust air to preheat incoming fresh air in ventilation systems.

Machine manufacturing

Heat exchangers cool down electric machines and components to prevent overheating. Besides, they are used in the hydraulic systems of construction machines and mining machines to cool down oil.

Agriculture

Heat exchangers are found in agriculture. Liquid cooling machines transfer heat to protect the crops from extreme temperatures. Besides, they are used in anaerobic digesters to maintain optimal temperature conditions for microbial activity to maximize biogas production.

Consider the following factors about the machines when choosing:

Capacity

Design and choose the amount of heat the machine will transfer. A small heat exchanger machine will transfer heat at a low rate. A big heat exchanger machine will transfer heat at a high rate. Also, think about the space for the heat exchanger machine in the factory.

Flow arrangement

Machines have different ways for fluids to flow. Crossflow and counterflow machines may exchange heat more effectively compared to mixed flow heat exchangers. Countercurrent heat exchangers are better than crossflow ones, but they are more difficult to build. Manufacturers may choose countercurrent designs because they perform better, use less space, or are cheaper to make.

Durability

The materials used to build the heat exchanger machine must last a long time. Strong materials like stainless steel can resist high temperatures, corrosion, and mechanical stress. Also, choose machines with protective coatings. These coatings give extra resistance and can improve the machine's life span.

Maintenance

Machines need regular maintenance. Consider the maintenance needs and choose heat exchangers with easy-access parts. If manufacturers choose easily serviceable heat exchangers, they may have to pay less for long-term maintenance.

Energy efficiency

More energy-efficient heat exchangers machines save money on energy costs. Energy-efficient machines may lower operating costs and improve profit margins.

Q1: How to choose a heat exchanger design?

A1: Consider factors such as the type of fluids being used, their temperature and pressure, flow arrangement, heat transfer efficiency, and space constraints. Different designs offer varying performance characteristics, so it’s essential to match the exchanger’s design with specific application needs.

Q2: What are some trends in the heat exchanger industry?

A2: Some trends in the heat exchanger industry include compact heat exchanger designs that save space without compromising efficiency, enhanced heat exchanger materials to improve durability and performance, and the retrofitting and optimization of existing heat exchangers to enhance energy efficiency and reduce environmental impact.

Q3: How can businesses ensure the quality and performance of industrial heat exchangers?

A3: When sourcing industrial heat exchangers for industrial applications, it’s crucial to collaborate with reputable manufacturers with a proven track record. It’s also important to conduct regular maintenance and inspections of the heat exchanger to avoid unexpected downtime and costly repairs.