(89101 products available)

There are several types of machines for clay that comprise the foundation of the pottery industry. They each differ in terms of the level of automation, processes they can perform, and the type of clay they are designed for.

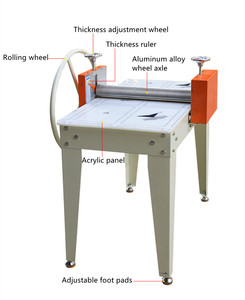

Clay cutting machines

Also known as clay splitter machines, these devices are used to cut large blocks of clay into smaller and more manageable pieces. They usually have a guided frame, a wooden board, and a thin wire or cable that strikes the clay. The clay cutting machine is essential for reducing the excess of clay in pot-making so that precise portions of clay can be used. This helps ensure consistent quality throughout the pottery process.

Clay mixing machines

These machines help to homogenize the composition of the clay by adding water and other additives to achieve the desired moisture content. Often automatic, the machine controls the mixing by weight and volume, ensuring uniform consistency across all batches of clay. Once mixed, the clay is removed from the machine through lift trucks, trolleys, or conveyors.

Clay extruder machines

Often regarded as the most versatile machine for clay, the clay extruder machine is used to make various pottery items like pottery, tiles, and bricks. The machine works by applying pressure to the clay to create uniform shapes that are known as extrusions. What’s more, the clay extruder can create different designs depending on the die used. It is a complex machine and may have features such as a hopper, screw mechanism, barrel, heating or cooling elements, and a pressure gauge.

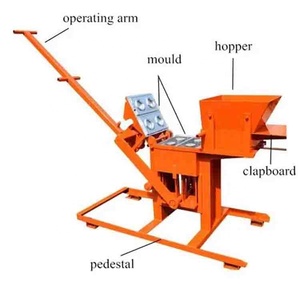

Clay molding machines

These machines work by shaping clay into desired forms using a specific molding technique. One such technique is the face plate and lever in which the operator presses the lever, which in turn moves the face plate towards the body of clay. Then, the clay is shaped to the desired item and specifications. The machine may be manual, semi-automatic, or fully automatic, depending on the level of control and precision required.

De-airing clay vacuum pugmill

The de-airing clay vacuum pugmill is used to knead and remove air from clay through a process called wedging. After de-airing the clay, the machine seals the clay in a vacuum chamber. A series of blades move the clay through the chamber before it is extruded through a die at the end of the chamber. The vacuum, in this case, is very essential as it helps prevent bubbles from forming in pottery, which can weaken and undermine its integrity.

De-airing clay vacuum pugmils can be either wet or dry, with the former being more common. The pugmil may include features such as a rectangular or circular container, a hydraulic or pneumatic system for extrusion, and safety guards.

Specifications for clay processing machines vary according to the machine in question.

Clay machines require regular maintenance to ensure they last a long and continue to work well. Here are some maintenance tips corresponding to the machines:

Mud or soil is discovered by the users all over the world as a significant source of income due to the unique characteristics of clay. The machines for clay have a wide range of applications among business buyers who invest in them for different purposes.

Construction projects

Soil cement is a property that, when combined with water and lime, creates a binding substance that can be used as a structural element like concrete. Soil cement, commonly known as stabilized soil, is a clay soil mixture that binds and is frequently utilized in road construction as a sub base or in intersections, driveways, and parking areas. Machine tools are widely used in road construction projects. For example, the clay mixing machine is generally applied to prepare stabilized soil for road base construction.

Brickmaking

A brick machine can make a wide range of bricks, including hollow bricks and interlocking bricks. A key component of urban development, bricks are made from clay and fired in kilns to produce ceramic building materials. The raw materials are uniformly distributed inside the machine thanks to the feeder and conveyor belt, where they are pressed into shape. The press, drum, or wire-cut methods are classic ways of molding wet clay into green bricks, which are eventually kiln-dried to make them hard and durable.

Pottery production

The pottery industry has undergone remarkable transformations over time, with various machines for clay now used to create pottery pieces. Pottery production uses the clay mixing machines, clay extruders, pottery wheel machines, and pottery tunnel kiln. The pottery machine allows creators to produce pots, vases, and other decorative items at an industrial level. These machines help business owners meet larger markets efficiently and affordably.

Artificial turf fields

Constructing playing fields with artificial grass requires persistent efforts to produce and install high-quality materials. Many players in this industry have to be economically efficient and environmentally sustainable. Clay is a necessary component of the infill material employed in imitation grass turf fields, and a clay crushing machine will assist ensure that the final product meets these objectives. Using a clay crusher not only fulfills processing needs but also supports environmentally friendly practices by minimizing waste through reuse.

When selecting a particular type of machine for clay, there are several important factors that need to be taken into consideration, such as materials compatibility, production capacity, automation and control, floor space requirements, and after-sales support.

When selecting a machine, the type of clay that it is suited for must be matched. For example, some clay-drying machines are better suited for specific types of clay. For instance, straying or spraying unlocked clay works well with the foam dry hopper but may not work well with other combined drying methods. Similarly, some types of clay may need a different type of drying machine altogether.

The production capacity refers to the amount of output that a machine can produce in a given period. This is a very important factor for mass-production businesses that need to keep up with high-demanding production rates. An ideal machine would produce at an optimum rate without compromising on quality. It is important to note that a machine's production capacity may depend on different factors, such as the size and complexity of the final product, the type of material being processed, the technology used by the machine (e.g., its automation level), and the operational efficiency of the machine.

Automation of a machine can greatly influence a production line's efficiency and output. Clay machines with automated processes can streamline operations, reduce manual intervention, and improve consistency and precision. On the other hand, machines that offer manual processes can provide more hands-on control and flexibility. Considering the level of automation needed in a production facility's workflow, integration, and scalability is essential.

The space available in a workshop or production line can also play an important role in choosing the right machine. It is important to ensure that the machine fits perfectly and works optimally in the available space. More importantly, it can be integrated into the production line without compromising efficiency. Before ordering large and heavy machines, their installation process should be looked into thoroughly so that the after-sales support team can guide the client through the seamless installation and integration of the machine into the production line.

Q1: Where are the machines for clay originated?

A1: The origin of clay machine materials can vary depending on the type of machine and its manufacturer. However, certain elements are commonly found in clay machines, such as ceramics. Clay machines' production involves mixing, shaping, and drying various types of clay. Metals like steel, aluminum, and certain alloys are used in different machine parts for their strength, durability, and resistance to wear.

Q2: What are the steps in clay processing in clay working machines?

A2: The process of working with clay can be broadly categorized into several key steps. Each step can be done using specific machines for clay. Usually, the steps are as follows: kneading or wedging, centering, shaping, trimming, piercing, adding handles or other attachments, drying, and firing.

Q3: How do clay-making machines improve production efficiency?

A3: Automation: Machines for clay, such as the potter's wheel and extruder, allow for more excellent production volume by automating repetitive shaping tasks. Consistency: Machines for clay provide uniformity in producing large quantities of identical items. Speed: Machines for clay increase production speed by streamlining the shaping, cutting, and finishing processes.