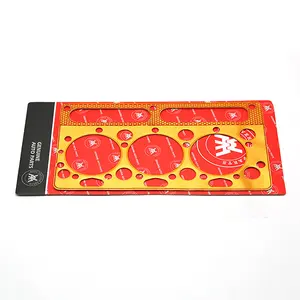

Introduction to MF Gasket

The MF gasket, or metal fiber gasket, is an essential sealing component renowned for its exceptional sealing performance in various industrial applications. Designed to withstand the rigors of dynamic operating conditions, MF gaskets are vital in preventing leakage in piping systems and other equipment where reliability and durability are paramount. Their unique composition allows them to cater to high-temperature and high-pressure environments, making them indispensable in sectors like oil and gas, chemical processing, and power generation.

Types of MF Gaskets

Understanding the different types of MF gaskets available can help users select the most suitable option for their applications. The most common types include:

- Spiral Wound MF Gaskets: These consist of alternating layers of metal and filler material, making them highly versatile and effective in a wide range of sealing situations.

- Composite MF Gaskets: Incorporating a mixture of materials, these gaskets offer enhanced strength and durability, suitable for critical sealing applications.

- Ring Joint MF Gaskets: Designed for high-pressure environments, these gaskets feature a round shape that ensures a tight seal, often used in flanged connections.

- Flat MF Gaskets: Simple in design, these gaskets are ideal for low-pressure applications and are compatible with various flange materials.

Applications of MF Gaskets

MF gaskets find applications in multiple industries due to their excellent sealing properties. Here are some key areas where MF gaskets excel:

- Oil and Gas Industry: Used in pipelines and downstream processing equipment, they prevent leaks and provide safety in handling toxic substances.

- Chemical Processing: Essential in reactors and storage tanks, MF gaskets ensure containment of hazardous chemicals under varying temperatures and pressures.

- Power Generation: Utilized in steam turbines and boiler systems, they maintain efficient energy production by minimizing leakage.

- Aerospace and Marine: In critical applications subject to vibrations and pressure fluctuations, MF gaskets provide robust sealing solutions.

Advantages of MF Gaskets

MF gaskets offer a variety of advantages that make them a choice sealing solution across different sectors. Some noteworthy benefits include:

- High Temperature Resistance: MF gaskets can operate efficiently at elevated temperatures, making them suitable for demanding environments.

- Excellent Chemical Compatibility: They are resistant to a wide range of harsh chemicals, ensuring longevity and reliability in hostile conditions.

- Durability: MF gaskets exhibit outstanding wear resistance, reducing the need for frequent replacements and maintenance costs.

- Enhanced Sealing Performance: Their unique design provides superior sealing integrity, preventing costly leaks and ensuring operational safety.