(6509 products available)

The development of the mini corn grinder creates opportunities for people and businesses to benefit financially from the corn milling business. Here are some mini corn grinders used for different purposes:

Manually operated grinders

Grinders that are operated manually are typically small devices manufactured from cast metal. They contain adjustable grinding plates and are mounted on a fixed surface. Users pour the corn into the grinder and turn a handle to move the grinding mechanism. This action crushes the corn. Although manually operated grinders are obsolete and less practical due to the manual effort they require, they are ideal for situations where electricity is unavailable.

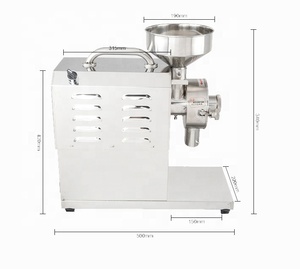

Electric-powered corn grinders

The mini corn grinder, which is powered by electricity, is now a more practical option. It possesses a motor that drives the grinding mechanism, and as a result, it offers more constant milling and higher production rates than grinders that are operated manually. Cornmeal is produced by simply pouring the corn into the feed hopper and turning on the machine. During operation, the corn is ground and ejected through the outlet.

The majority of electric grinders are made of heavy-duty plastic and stainless steel. They also have safety features like motor overload protection to prevent accidents. Furthermore, some models allow users to adjust the size and coarseness of the cornmeal by modifying the milling settings, which are generally easy to clean and maintain. Electric grinders can use battery or AC power depending on the model. Grinders that operate with AC power are more powerful and ideal for use at home, while those that operate with battery power are more portable.

Wet corn grinders

Wet processing is used to prepare crops for livestock. A wet corn grinder is a piece of machinery that mashes the corn into a wet paste by adding water to the whole corn. The paste is fermented and processed into animal feed. Fermented corn has a distinct aroma and enhances the animal feed's palatability, making it more appealing to the animals. Weight loss from the fermentation process is one drawback of wet corn milling.

Universal corn grinders

Using a single machine to perform multiple tasks lowers production costs and increases efficiency. The universal corn grinder stands out because it handles wet and dry corn milling. It mushes dry corn into cornmeal or flour, and when processing wet corn, it produces a paste. The grinder also features interchangeable sieves and hammers that allow users to easily and quickly modify the machine to adjust the products' specifications.

Puerto Rican corn grinders

This machine's primary function is to produce cornmeal, primarily for use in restaurants, but it is also suitable for domestic use. It operates by crushing corn between steel plates. The final product emerges between the plates and is discharged through an outlet chute. Owners can easily modify the machine to produce coarser or finer cornmeal by adjusting the distances between the plates. Additionally, Puerto Rican corn grinders are available in electric and gas-powered models. Gas models are ideal for use in remote locations without access to electrical power.

The mini corn grinder has many application scenarios, and it is used widely in the food industry and agricultural field.

Small-scale farms or rural households use mini grinders for corn to make animal feed. They process whole corn kernels into coarse or fine powder as customized nutrition for different livestock. The grinder gives flexibility to small farmers who want to use various grains or adjust the feed's texture to meet their animals' changing needs.

Mini corn grinders are helpful tools for home cooks and small-scale food processors. They grind small batches of corn into flour for various homemade products such as tortillas, bread, porridge, and snack foods. The fresh flour adds distinctive flavors and textures to traditional recipes while allowing cooks to control ingredients.

Mini corn grinders are helpful tools for home cooks and small-scale food processors. They grind small batches of corn into flour for various homemade products such as tortillas, bread, porridge, and snack foods. The fresh flour adds distinctive flavors and textures to traditional recipes while allowing cooks to control ingredients.

In developing countries where access to centralized milling facilities is limited, mini corn grinders provide an affordable solution for rural communities to process their staple food efficiently. By transforming whole corn cobs into flour or meal suitable for consumption within individual households instead of relying solely upon external resources for food production and processing systems facilitates greater food sovereignty by empowering local populations economically through increased self-sufficiency.

Restaurants, cafes, and catering services use mini corn grinders to mill fresh corn flour for making tortillas, dumplings, pizza bases, baked goods, and other specialty items. The on-site grinding ensures product freshness and flavor while attracting customers. Offering freshly ground corn products adds uniqueness to the menu selections and enhances the overall dining experience.

Business buyers searching for a corn grinder for sale should consider the following factors: performance, multipurpose applications, ease of use, durability, design, material, and safety features.

Evaluate the grinding performance of the corn mill machine. Look at the efficiency, output, and quality of the final product. Some corn grinders produce fine cornmeal, while others will have a coarser output. Consider the taste and texture that the customers want to buy. If clients have various preferences, it's best to choose a model that can grind corn into different types of flour. Also, let the corn grinder for sale be easy to use. The operating and maintenance processes should be simple. New employees won't need extensive training to learn how to use the machine.

Find a grinder built with sturdy materials like cast iron or stainless steel. It should also last a long time and have removable parts for quick cleaning. Look for a mini-corn grinder with safety features that prevent accidents. For example, check that the grinder has non-slip equipment and safeguards against overheating or jamming.

Q1: Are there other crops people use the mini corn grinder to process?

A1: Yes, farmers and food manufacturers use the mini corn grinder to process various crops into flour or meal. Some of them include beans, rice, millet, wheat, oats, chickpeas, barley, and sorghum.

Q2: Is electrical power availability a factor in using a mini corn grinder?

A2: Yes, the availability of electrical power can affect a mini corn grinder's use and suitability. Corn grinders that use electricity might not be suitable for places with no electric power. Such locations might prefer the grinders that use hand power or gas engines.

Q3: How does a mini corn grinder affect the texture of ground corn products?

A3: The mini corn grinder's grinding mechanism and settings determine the texture of the ground corn. Some grinders have milling plates or blades, which produce finely ground corn. Others have coarser settings for producing roughly ground corn.

Q4: Can a mini corn grinder overheat during continuous use?

A4: Yes, when grinding large quantities of corn continuously without breaks, the grinder may overheat. Some mini grinders come with overheating protection mechanisms. Users should also take breaks after prolonged use to prevent overheating.