(637 products available)

Municipal Solid Waste (MSW) processing equipment plays a crucial role in waste management by safely and beneficially recycling, treating, or disposing of solid wastes from residential, commercial, institutional, and industrial sources. The types of MSW processing equipment may vary according to different waste management approaches.

The municipal solid waste processing machine has several specifications that vary according to design and purpose. The following table summarizes some key specifications and their explanations.

Capacity

This refers to the amount of waste an MSW processing equipment can handle within a specific timeframe.MSW shredders, for example, have capacity ranges that fall between 1,500 and 6,000 kilograms per hour. Higher capacities can increase economies of scale for waste management systems.

Horsepower

Municipal solid waste processing equipment, such as shredders and compressors, have different horsepower ratings. This determines how powerful the motor driving the machines is. A higher horsepower rating, such as 55/110 for some shredder motors, gives the equipment more physical power to handle larger volumes of waste. This ultimately leads to smoother processing and less frequent downtime.

Energy Efficiency

The energy efficiency of a piece of MSW processing equipment is the total energy it consumes during a shredding cycle, divided by the amount of waste it reduces. Some machines convert 2.4kWh into one ton of shred waste, while others need less. More energy-efficient machines help to lower operating costs and lessen the environmental impact by using less electricity.

Technology

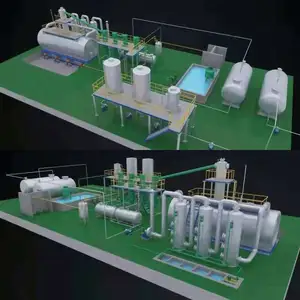

Different MSW processing technologies are used around the world to manage waste. Some common examples include anaerobic digestion, gasification and incineration. Each technology has its own pros and cons, as well as suitable applications.

Proper maintenance boosts the performance, reliability and efficiency of municipal solid waste processing equipment. During routine maintenance, the waste processor is inspected, adjusted, oiled and cleaned. This helps to prevent breakdowns, reduce repairs and prolong useful life. The following tips can help users maintain their waste processors.

Municipal Waste Management Facilities:

MSW processing equipment is commonly used in municipal waste management facilities. It assists in the segregation, recycling, and disposal of various types of waste materials efficiently.

Industrial Waste Treatment:

Industry factories produce a large amount of waste. Applying MSW processing equipment can effectively reduce the waste's treatment cost and improve the value of residua by recycling them.

Food Waste Processing:

Food waste is one of the significant parts of municipal solid waste. Applying specific MSW processing equipment can increase dealing with efficiency and reduce environmental pollution.

Recycling Centers:

Recycling centers are responsible for collecting and treating recyclable materials. MSW processing equipment can help sort and process these materials, such as plastics, paper, metals, and glass, to recover valuable resources.

Landfill Diversion:

Many countries and regions are trying to lessen the use of landfills. MSW processing equipment can deal with waste prior to landfilling, assisting in reducing the volume of waste sent to landfills and making extraction of recyclables.

Society Educational Institutions:

Universities and colleges produce a large amount of waste not only from the school premises but also from research and innovation institutes. Adopting MSW processing equipment can efficiently reduce waste output and facilitate sustainable campus practices.

Construction and Demolition Sites:

Cities produce a large amount of waste not only from routine activities but also from the construction and demolition of projects. MSW processing equipment can deal with the waste on-site, reducing the need for decentralization and the use of land filling.

Proper selection of solid waste disposal equipment is crucial to ensure minimum waste output and maximum recycling rates. It is advisable to conduct a thorough analysis of the types of equipment available for municipal solid waste and categorize them according to the needs of the processing site.

Assess the daily waste volume and composition:

TheSelecting an appropriate type trash of waste processing machine depends on the composition and amount of waste generated each day. Some machines are scale to handle higher volumes of waste, such as daily municipal waste, while others are suitable for smaller businesses or household waste. Furthermore, It is essential to consider what parts of waste are likely to encounter plastic, organic, e-waste, and other types of waste. The separation and processing requirements for different types of waste vary, as some are contaminated with organic matter, while others are dry and recyclable. SomeSuch types of waste, such as e-waste, may require specialized shredders for municipal solid waste with advanced technology and expertise.

An analysis of the available budget and required revenue:

Various municipal waste processing machines are available at different price points, from low-cost solutions like manual sorting systems to more sophisticated ones like AI-enabled sorting systems. In addition to the initial investment, the processing equipment has to incur running costs. Amachine that has an energy-efficient design can help save costs in the long run. Sorting waste at an early stage helps avoid expensive, high-maintenance waste shredders.

Q1: What are the latest technologies in MSW processing equipment?

A1: The latest trends in municipal solid waste processing equipment are waste-to-energy, AI and automation, and the Internet of Things. Waste-to-energy refers to technologies like incineration, gasification, and anaerobic digestion that convert organic waste into energy or fuel. AI and automation involve using intelligent machines that can separate waste by itself, which makes sorting more precise and efficient. The Internet of Things means connecting machines through the internet so they can communicate and be monitored remotely, resulting in smarter waste management systems.

Q2: How do MSW processing equipment suppliers ensure the safety and environmental compliance of their products?

A2: MSW processing equipment suppliers make sure their products are safe and eco-friendly by following rules set by the government. They design their machines to meet safety standards and use materials that comply with environmental regulations. The suppliers also conduct tests on their equipment to verify that it meets the required environmental compliance. In addition, the suppliers implement quality control systems to ensure that their products are manufactured properly and sustainably.

Q3: What is the role of sorting equipment in MSW processing?

A3: The role of sorting equipment in MSW processing is crucial. It helps separate different types of materials in municipal solid waste, like paper, plastic, glass, metal, and organic matter. By distinguishing valuable recyclable materials from non-recyclable ones, sorting devices lay the groundwork for further processing. The items are collected, segregated, and delicately handled by sorters like conveyor belts, trommel screens, air classifiers, and magnetic separators. Sorting equipment boosts recycling rates, cuts down on landfill use, and adds to more sustainable waste management methods.

Q4: What are the trends in waste separation technologies for MSW processing?

A4: Automated waste segregation methods have grown in popularity as a result of technology breakthroughs, including artificial intelligence (AI) and machine learning. To improve the accuracy and efficiency of waste segregation, AI-powered cameras and optical sensors are now being used in municipal solid waste (MSW) processing equipment. Additionally, there is a rising interest in developing waste separation equipment that can handle complicated waste streams, such as those produced by commercial and industrial settings.