(3895 products available)

Single turbo

It is perhaps the most common type of turbo found in the Nissans. In a single turbo setup, just one turbocharger is used to compress the exhaust gasses. This leads to increased airflow into the engine, which results in more power. Single turbo Nissans are often lighter, simpler, and cheaper to maintain. However, they suffer from turbo lag, which is the delay in power delivery that is noticed when stepping on the gas pedal. Also, the single turbo might struggle to produce power at higher RPMs.

Sequential Turbos

As the name suggests, the sequential turbo system uses two turbos. The first turbo is a smaller unit that spools up quickly and provides boost at lower engine RPMs. The second one is a larger turbo that kicks in at higher engine RPMs. By using two turbos of different sizes, the sequential turbo system ensures a smooth and linear power delivery throughout the entire power band. The only downside to the sequential turbo system is that it is quite complex and therefore expensive.

Twin-turbo

Similar to the sequential turbo system, the twin-turbo configuration also uses two turbochargers. However, both turbos are of the same size. The twin-turbo setup is mostly found on high-performance engines. The use of two similarly sized turbos leads to quicker throttle response and improved power delivery when compared to the single turbo setup.

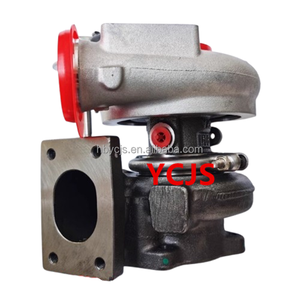

The specifications of N S Turbo parts are important considerations for any business looking to acquire these components. Generally, the specifications of these components differ depending on the model and make.

Turbine Wheel Diameter:

The turbine wheel diameter is a significant consideration when selecting N S turbo parts. It impacts the power and efficiency of the turbo. Typically, the turbine wheel diameter ranges between 40 mm and 70 mm.

Compressor Wheel Diameter:

Like the turbine wheel diameter, the compressor wheel diameter impacts the power and efficiency of the turbo. The compressor wheel diameter on N S turbo parts ranges from 40 mm to 80 mm.

Trim Ratio:

The trim ratio is a specification that affects the performance of the turbo. The trim ratio of the turbine is often between 60 and 80. On the other hand, the compressor trim ratio ranges from 50 to 70.

Maximum Boost Pressure:

Maximum boost pressure is an important specification that influences the power output of the engine. The maximum boost pressure on N S turbo parts typically ranges from 0.5 bar to 2.0 bar.

Turbo Size:

N S Turbo parts come in different sizes. The size of the turbo determines the power output and efficiency. Generally, the turbo size is categorized as small, medium, or large. Small turbos spool quickly but offer a limited boost range. On the other hand, large turbos have a delayed spool time but provide a broader boost range.

Maintaining N S turbo components is vital for ensuring they have a long lifespan and optimal performance. The following are some general maintenance requirements for N S turbo parts.

Oil Changes:

Oil changes should happen at the recommended intervals. This ensures that the turbo receives proper lubrication and stays clean. Additionally, users should only use oil that meets the manufacturer's specifications.

Clean Air Filter:

A clean air filter prevents debris from entering the turbo and causing damage. Users should check the air filter regularly and clean or replace it when necessary.

Cool Down:

The turbo should not be used immediately before or after turning on the engine. This is because the turbo needs a cooling down period to avoid damage.

Inspect Hoses:

The hoses need regular inspections for wear and tear. Damaged hoses should be replaced immediately to prevent turbo issues.

Check Boost Pressure:

Boost pressure should be checked regularly using a gauge. If the boost pressure is low, it could indicate a problem with the turbo.

Understand the Engine:

Reading the car's manual helps one understand the engine's features and requirements. This is important since different engines require different kinds of turbos for optimal performance.

Evaluate Driving Needs:

One's driving habits are also an important factor when choosing an N s turbo. If one drives in a calm manner, a turbo that is designed for fuel efficiency would be a better fit. Alternatively, if one's driving style is more aggressive, a turbo that focuses on high power output might be the better choice.

Consult with Professionals:

Mechanics and other car experts provide valuable information when choosing the right N s turbo. These professionals have experience working with different cars and turbos, so they can recommend what would work best.

Consider Budget:

It's important to choose an N s turbo that provides the desired performance without breaking the bank. More expensive turbos often provide more power but require higher maintenance costs.

Future Considerations:

If one plans on making future modifications to the car, such as upgrading the exhaust system or increasing the engine's efficiency, it is advisable to consider a turbo that can handle these changes. This ensures compatibility and maximizes benefits from the upgrades.

Some turbochargers are easy to replace as long as one has the right tools and mechanical knowledge. The tools required for the job include a socket set, a wrench set, a torque wrench, an extension, a ratchet, a gasket scraper, a new turbocharger kit, and a new turbo oil feed line. One must also have a basic mechanical knowledge of how engines work to be able to replace an N s turbo.

Firstly, the ns turbo part that needs replacing is located under the hood. Then, disconnect the battery before starting the replacement. After that, remove the engine cover to get more room to work. The next step is removing the intake system going to the turbo and the exhaust downpipe connected to the turbo. After that, disconnect the oil feed and return lines. One must be careful with this step not to make a mess with the engine oil while disconnecting the lines.

Remove the wastegate actuator and oil lines, and then unbolt the turbo from the manifold. The next step is removing the turbo from the manifold. This step might require an extension and a ratchet to reach the bolts holding the turbo in place. Now, the old turbo can be replaced with a new one. Reassembly is the last step, and it is done by reversing the steps above. One important thing to note when replacing a turbo is that it needs to be broken in properly to avoid damage.

Q1: How does a turbocharged engine work?

A1: A turbocharged engine uses a turbine-driven forced induction device called a turbocharger to boost the engine's power. The turbocharger uses exhaust gases from the engine to spin a turbine, which draws in more air and forces it into the engine. This extra airflow allows the engine to burn more fuel, resulting in increased power output without increasing the engine's physical size.

Q2: What is the difference between a turbo and a supercharger?

A2: The main difference between a turbo and a supercharger lies in how they are powered and the source of the air they provide. Turbos are powered by the exhaust flow from the engine, while superchargers are mechanically driven by a belt connected to the engine's crankshaft. As a result, superchargers provide immediate boost but can drain horsepower, whereas turbos provide boost at higher RPMs but are more efficient overall.

Q3: Does turbocharging affect engine reliability?

A3: When properly installed and maintained, turbocharging does not inherently affect engine reliability. However, it's crucial to ensure that the turbocharger is compatible with the engine and that both components are of high quality. Turbocharged engines may operate at higher temperatures, so adequate cooling and monitoring are essential to maintain engine reliability.

Q4: Can any engine be turbocharged?

A4: In Ns turbo any engine can be turbocharged, but the process requires careful engineering and modification. Adding a turbocharger changes the dynamics of the engine, so the fuel system, exhaust system, and intake system need to be upgraded to work with the new components. Additionally, the engine must be able to handle the increased pressure and temperature from the turbo.

Q5: What are the benefits of turbocharging an engine?

A5: Turbocharging an engine has several advantages. It improves power output and efficiency, resulting in better fuel economy. Turbocharged engines also provide better performance at high altitudes and can reduce emissions by allowing more complete combustion of fuel.