(3262 products available)

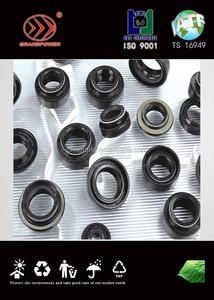

NOK crankshaft oil seal

The crankshaft is the heart of the engine. It converts the up and down motion of the pistons into rotational movement. The crankshaft has two sets of bearings: one on the outside for lubrication and another for the timing belt or chain. The external bearings are the ones that need sealing. The NOK crankshaft oil seal sits in a groove around the crankshaft. Its job is to stop engine oil from leaking out and stop dirt and dust from getting inside the bearings. The seal is made of durable rubber that fits tightly against the crankshaft metal. As the crankshaft spins, it brushes up against the seal. This friction keeps oil contained. The seal is also spring-loaded, which means it has a tiny coil spring inside. The spring puts extra pressure on the seal against the crankshaft. This ensures a snug fit and makes it even harder for oil to escape. Crankshaft seals are very important. A small leak could cause all the engine oil to drip out over time. Then the engine would run dry and get damaged. The NOK crankshaft oil seal prevents this by keeping the oil inside where it belongs.

NOK axle oil seal

Once the engine produces power, the drive axles transmit that power to the wheels. The drive axles rotate so the wheels can roll down the road. Like the crankshaft, the drive axles have external bearings that need sealing. The NOK axle oil seal sits in a groove around the outside of the axle shafts. It seals the bearings to keep grease inside and stop dirt from getting inside. The seal is made of tough material that holds up against road debris. There is also a metal casing around the seal. This helps it fit snugly into the holes on the wheel hub and transmission. Axle oil seals are important because, without them, the grease would eventually dry out. Then, the bearings would run dry and start to grind. This could cause the bearings to fail over time. The NOK axle oil seal prevents this by keeping the grease contained.

NOK hydraulic oil seal

Hydraulic seals stop pressurized oil from leaking out of the pumps, valves, and cylinders that move heavy equipment. The NOK hydraulic oil seal is a special seal that holds up against high-pressure oil. It contains several metal rings, each with a different job. The first rings are called retaining rings. They keep the other seals in place. Then come the backup rings. These are tough rubber rings that seal the gaps and stop oil from seeping out. Next is the wiper seal. Its job is to scrape any dirt or dust off the rods before they go inside the piston. This protects the other seals from abrasion. Finally, the last ring is the piston seal itself. It fits tightly between the piston and the cylinder wall. The seal blocks oil from leaking out and creates a tight barrier between the two sides. The NOK hydraulic oil seal keeps the oil pressure high so the pumps and motors can generate maximum force to move heavy loads.

The specifications of NOK oil seals are designed to meet the needs of different applications and industries. Here are some common oil seal specifications:

Material

NOK oil seals are made of high-quality materials that have excellent wear resistance and chemical stability. Commonly used materials include Nitrile Rubber (NBR), Fluororubber (FKM), and Polyacrylate Rubber (ACM). NBR seals have good elastic properties and are widely used in oil and water environments. FKM seals have excellent chemical resistance and thermal stability and are suitable for high-temperature and high-pressure applications. ACM seals have good oil resistance and aging resistance, making them suitable for harsh environments.

Size

NOK oil seals are available in various sizes to fit different shaft diameters and housing openings. The size of an oil seal is specified by three dimensions: the inner diameter (ID), the outer diameter (OD), and the width (W). For example, an oil seal with an ID of 25 mm, an OD of 40 mm, and a width of 7 mm would be denoted as 25-40-7.

Design

NOK oil seals can have various designs and structures, including single-lip, double-lip, and auxiliary lip seals. Single-lip seals are the most common and suitable for low-speed shaft sealing. Double-lip seals have two lips that provide better sealing performance, especially in the presence of dust or moisture. Auxiliary lip seals have an auxiliary lip that contacts the shaft surface to improve sealing performance and wear resistance.

Spring

Some NOK oil seals use metal or plastic springs to improve sealing performance and wear resistance. Springs provide constant contact pressure between the seal lip and the shaft surface, ensuring a tight seal. The type and material of the spring may vary depending on the specific application and sealing requirements.

Sealing Performance

NOK oil seals are designed to have excellent sealing performance, preventing oil leakage and protecting the shaft from dust, water, and other contaminants. They are tested and evaluated according to international standards and industry standards to ensure reliable sealing performance.

Temperature and Pressure Resistance

NOK oil seals are designed to withstand high and low temperatures and varying pressures. The specified temperature resistance range and pressure rating are used in different applications and environments to ensure stable operation and sealing performance.

Maintaining NOK oil seals is essential to ensure their long-lasting performance and prevent oil leakage. Here are some tips for maintaining NOK oil seals:

Regular Inspection

The NOK oil seals should be routinely examined for signs of wear, damage, or leakage. It is essential to conduct regular inspections of the oil seals, as early detection can help prevent seal failure and oil leakage. When conducting inspections, the condition of the seal lip, body, and sealing surface should be checked. In addition, oil stains, moisture, or dust near the oil seal should be inspected.

Cleaning

The oil seals and their surrounding areas should be cleaned regularly to prevent dirt, dust, and contaminants from interfering with their performance. When cleaning, mild detergents and water can be used. High-pressure cleaning or harsh chemicals should be avoided since they may damage the oil seal.

Alignment and Installation

The NOK oil seals should be properly aligned and installed according to the manufacturer's instructions. Improper alignment and installation can cause uneven wear and premature failure of the oil seal. During installation, ensure the oil seal is fully inserted into the housing and that there is no gap or misalignment between the seal lip and the shaft.

Lubrication

Before installing a new NOK oil seal, a thin layer of grease should be applied to the seal lip to ensure proper lubrication and sealing. Lubrication helps reduce friction between the oil seal and the shaft, extending the seal's life. Ensure that the lubricant is compatible with the oil seal material and the fluid being sealed.

Load and Speed Limits

Adhere to the specified load and speed limits of the NOK oil seals. Exceeding these limits can cause overheating and premature failure of the oil seal. Avoid sudden changes in load or speed, as this may stress the oil seal and affect its performance.

Replacement

Consider replacing the oil seal if any signs of wear, damage, or leakage are detected, even if the leakage is not apparent. Delaying replacement can lead to more significant problems, including oil leakage and damage to surrounding components.

Choosing the right NOK oil seal for a job requires careful consideration of several factors to ensure optimal performance and durability.

Seal Size

Selecting the correct seal size for the application is important. This includes the shaft diameter, housing bore, and seal part number. The seal has to be accurately sized to prevent leaks and reduce premature failure.

Seal Design

NOK has various seal designs, each suited for specific applications and operating conditions. Depending on the application, a lip or rotary seal design can be selected.

Material Composition

The material of the seal is an important factor to consider when choosing NOK oil seals. The material should be compatible with the sealed fluid and the operating environment. Some common materials used are NBR, HNBR, FKM, and PTFE.

Application and industry

Environmental Conditions

Speed and Temperature

Pressure

Type of Fluid Being Sealed

NOK oil seals can be replaced easily. Here are some of the steps that will be taken

Q1: What are NOK oil seals used for?

A1: Generally, NOK oil seals are used to prevent the leakage of liquids or gases in machinery and equipment. They seal the interface between two components, such as a rotating shaft and a stationary housing, to keep lubricants like oil and grease from leaking out and to keep contaminants like dirt and water from getting in.

Q2: Where are NOK oil seals used?

A2: NOK oil seals are used in various applications, including automotive engines, gearboxes, axles, wheels, industrial machinery, construction equipment, and any rotating parts that require sealing to prevent leakage and contamination.

Q3: What are the different types of NOK oil seals?

A3: NOK oil seals come in different types, including lip seals, rotary shaft seals, hydraulic seals, and mechanical seals. The seals are designed for different applications and customized to meet specific sealing requirements.

Q4: Are NOK oil seals good?

A4: NOK oil seals are generally considered good. They are known for their quality and durability, making them a suitable choice for sealing applications. However, the performance of NOK oil seals can depend on various factors, including the specific type of seal, the material, the application, and the installation.