(20 products available)

Market Overview: The industrial cooling systems market is witnessing robust growth, with the global market estimated at US$20.0 billion in 2023 and projected to reach US$28.7 billion by 2030, growing at a CAGR of 5.3%, according to Global Industry Analysts, Inc. Within this landscape, Orion chillers are positioned to benefit from the rising demand for efficient cooling solutions. The Evaporative Cooling Systems segment alone is expected to reach US$11.6 billion by 2030, illustrating a significant shift towards energy-efficient technologies. In regions like the U.S., the market is valued at approximately US$5.2 billion in 2023, while China is forecasted to grow at an impressive 8.2% CAGR, reaching US$6.5 billion by 2030. This regional insight underscores the competitive environment where Orion chillers can thrive, particularly as industries seek sustainable and cost-effective cooling options.

Consumer Behavior and Industry Trends: The increasing focus on energy efficiency and environmental sustainability is driving consumer preferences toward advanced cooling solutions. Industries are increasingly opting for chillers that not only meet operational needs but also align with global sustainability goals, such as using refrigerants with lower global warming potential. The shift towards smart and connected HVAC systems is also notable, as consumers demand integrated solutions that enhance operational efficiency and reduce energy consumption. Moreover, the maritime sector presents an emerging niche for absorption chillers, with significant opportunities driven by waste heat recovery systems. The demand for Orion chillers, particularly in these evolving sectors, reflects broader trends towards innovative, energy-efficient technologies that address contemporary industrial challenges.

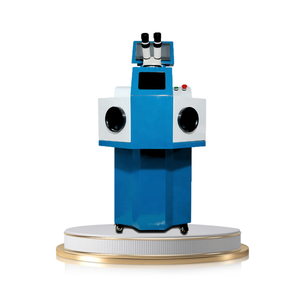

Orion chillers are industrial cooling devices that regulate the temperature of machinery and products within a facility. There are two main categories of Orion chiller systems: air-cooled and water-cooled chillers. Each type has distinct characteristics that make them suitable for particular applications.

Air-Cooled Orion Chillers

An air-cooled chiller uses atmospheric air to disperse heat from the refrigerant inside. It contains an outdoor fan that absorbs heat from the refrigerant and releases it back to the atmosphere. An air-cooled Orion chiller is independent of water supplies and is easier to install. Hence, it is a popular choice for many businesses. Three typical types of air-cooled chillers are scroll, screw, and piston.

Water-Cooled Orion Chillers

A water-cooled chiller dissipates heat with the assistance of water. This type of chiller needs a cooling tower or heat exchanger to release heat. Water-cooled Orion chillers are more energy-efficient than air-cooled ones. However, their installation requires more consideration of available water sources and the setup of cooling equipment.

The water-cooled Orion chiller is available in two compressor options: screw and centrifugal. The latter offers higher efficiency than its counterparts, especially in large-capacity models.

This section outlines the specifications and maintenance procedures for the proper functioning of the Orion chiller.

Different industries require various Orion cooling capacities to suit their purposes. The model number indicates its cooling capacity in kW. For example, the ORC-0620 has a cooling capacity of 620 kW. Another way to determine the cooling capacity is by looking at the condenser model. For instance, the air-cooled condenser models use the prefix CAD, and the water-cooled models use CWD, followed by a certain size that indicates its cooling capacity.

An environmental-friendly refrigerant is essential in any cooling machine to prevent adverse climate impacts. The type and amount of refrigerant affect factors like energy consumption and cooling efficiency. An example of a refrigerant used is the R-134A and R-513A. These two types are both HFC (Hydrofluorocarbon). They contain no ozone-depleting chlorine atoms and have a lower global warming potential compared to conventional refrigerants.

The chilled water temperature is another key specification for the proper functioning of an Orion cooler. An Orion chiller usually delivers chilled water at a specific temperature. For example, if the system's design temperature is 45 °F (7 °C), it will produce water at this temperature. A precise chilled water temperature ensures proper heat exchange and efficient cooling performance in applications such as air conditioning and industrial processes.

The fan's rotational speed, a component of the Orion cooler, determines the amount of airflow produced by the cooler. Typically, the fan speeds range from 1,900 rpm to 2,500 rpm. The more the rotational speed, the more refrigerant evaporated, resulting in more heat absorbed from the coil, increasing the amount of chilly air blowing out of the cooler's vent.

To maintain an Orion cooler, one must frequently inspect the chiller and check for any sign of leakage, which may be a potential problem. Inspection of components like the condenser coil, fans, and filters to see if there's any dirt, debris, or build-up that may affect their functioning is also crucial. Maintaining proper airflow around the chiller is vital since it prevents overheating, which can result in damage to the machine. Installing the chiller in a well-ventilated area would help achieve this.

It is also important to schedule regular professional maintenance services. An expert would inspect the system, adjust the controls, lubricate moving parts, and ensure all components function properly and efficiently. Following the manufacturer's guidelines for periodic maintenance is necessary for all machines and equipment.

Orion portable spot coolers are commonly used commercially, as well as Orion outdoor chiller machines. Some common application scenarios include the following:

Data centers and server rooms

Orion chillers are widely used in data centers and server rooms to maintain the proper temperature of the equipment. Because of their constant flow of heat removal. This ensures that the servers, networks, and other critical components are functional and well. Protecting them from any overheating incident that might deteriorate their performance.

Industrial manufacturing

Chillers carry on their usual roles with great ease and efficiency in the manufacturing industries. They cool down molds and cuts, control processing and ambient temperatures, and even help industrial refrigeration systems to work better. Their constant presence protects product integrity and maximizes production lines, making them indispensable for the smooth development of factories.

Food and beverage processing

In the areas where food and beverages are made, Orion chillers have a lot of uses. They help keep the area at a cool temperature while also providing precise control over the temperature of the processing. Additionally, they are part of cold storage and refrigeration systems. All of this ensures that the quality and freshness of the products are maintained.

Medical and pharmaceutical facilities

From the production to the storage and distribution phases of medicines, chillers play a role in temperature control. This control is critical to ensuring that medicines are reliable and precise. As a result, chillers are crucial instruments in safeguarding public health and the efficacy of medical services.

Event cooling and temporary cooling

Chillers can provide immediate cooling needs. For example, they can support outdoor activities and temporary cooling solutions. This could include anything from outdoor festivals and concerts to sporting events and corporate gatherings. As a rapid response to temperature regulation, they are flexible and can solve problems fast.

Aerospace and automotive industries

Chillers are extensively used in the aerospace and automotive industries for applications such as mold cooling, welding, machining, and surface treatment. They offer precise temperature control and ensure stable cooling, which enhances the quality and productivity of the manufacturing process.

Determine the Load Requirement:

An essential step in selecting an Orion chiller is figuring out the load demand. It involves conducting a detailed assessment of the cooling demand of the application. Factors such as the heat generated by equipment, the building's thermal properties, and desired temperature must be considered. An accurate analysis of the load requirement enables buyers to choose a chiller with the correct capacity.

Consider Energy Efficiency:

Energy efficiency is a crucial factor when choosing an Orion chiller. Look for models with high energy efficiency ratios (EER) or coefficients of performance (COP). These measures indicate the cooling power provided per unit of energy consumed. Selecting an Orion chiller with optimal energy efficiency helps reduce operating costs and environmental impact.

Assess Available Space:

The physical space an Orion chiller occupies is also an essential consideration. Buyers should thoughtfully measure the available installation area and determine if there's enough space to install the unit properly. Space considerations ensure that the chiller can be accommodated without compromising other systems or areas.

Evaluate Noise Levels:

Another aspect to consider when choosing an Orion chiller is its noise level. In some applications or installation locations, excessive noise can be disruptive or create compliance issues. Opt for coolers that produce lower noise levels to ensure quieter operation and minimize disturbances. Chill at a cooler that meets specific requirements, whether away from residential areas or within close proximity to occupied spaces.

Understand Control Options:

Different models of Orion coolers have various control options. These range from simple on/off controls to advanced digital controls with programmable settings, remote monitoring, and integration with building management systems. Consider the desired level of control and automation for the application, and choose a chiller with appropriate control features to ensure precise temperature regulation and convenient system management.

Q1: Do Orion Chillers require a specific type of coolant?

A1: This typically depends on the machine's design and functionality. Most will use water or air as coolants. However, for more efficient performances especially in high-demand industries, refrigerants like R134a or R404A might be preferred.

Q2: How can one tell if the Orion Chiller is not functioning properly?

A2: There are a couple of ways one could tell that the chiller is not functioning as it should. Some includes: abnormal changes in the temperature of the machine being cooled, noisy operation, error messages on control panel, constant high refrigerant pressure, low refrigerant pressure, continuous running without cycling, and ice buildup on evaporator coils.

Q3: Do Orion Chillers require regular maintenance?

A3: Yes. A regular maintenance schedule is crucial if the goal is to optimize its performance, increase its lifespan, and prevent unexpected breakdowns.

Q4: How long do Orion Chillers typically last with proper maintenance?

A4: With proper maintenance, an Orion Chiller can last 10 to 15 years or even longer in some cases.

Q5: Can Orion Chillers be upgraded or modified with additional features?

A5: Yes. It is possible to upgrade or modify some Orion Chillers with add-on features such as noise reduction kits, variable speed drives, predictive maintenance technology, or advanced filtration systems.