(1130 products available)

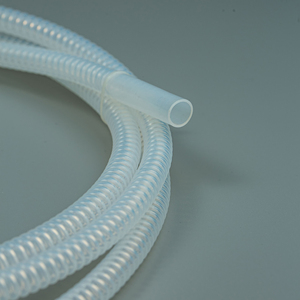

Fluoropolymers PFA and FEP are well known for their high performance in various industries. They are combined into tubes to transfer fluids and gases in different applications. PFA FEP tubes are plastic tubes offering chemical resistance, high-temperature resistance, and electrical insulation. They are used in different applications, including electronics, aerospace, automotive, and chemical industries. These tubes are popular among manufacturers because they are lightweight and flexible. They enhance efficiency in applications requiring fluid and gas transfer.

The PFA FEP tubes come in different sizes, diameters, and lengths. They also have different thicknesses and are used for specific applications. Here are the types of PFA FEP tubes:

PFA Tubing

Perfluoroalkoxy (PFA) tubing is a type of FEP tube. It is preferred in applications that require flexibility and a wide range of operating temperatures. PFA tubing is popular in pharmaceutical and food processing industries. It is autoclavable and meets stringent regulatory requirements. It is available in different sizes and diameters. It can be produced as transparent PFA tubing or as a colored PFA tubing for specific applications.

FEP Tubing

FEP is a fluoropolymer resin that is popular for its high chemical resistance and low friction properties. The FEP tubing is commonly used in applications where reduced permeability is required. It is used in electrical and electronic applications. The FEP tubing has a smooth inner surface, making it ideal for transferring fluids with low shear.

PTFE Capillary Tube

The PFA FEP tube also includes PTFE capillary tubes. They are long, thin tubes with internal diameters. They are used in applications requiring the precise flow of liquids or gases. PTFE capillary tubes have low surface tension, which makes them ideal for moving fluids with high accuracy and without leakage. They are commonly used in medical devices, chromatography, and scientific research.

PTFE Rods and Sheets

Manufacturers also produce PFA FEP tubes in the form of solid rods and sheets. These products are versatile and can be used in various applications. They offer excellent wear resistance, low friction, and high-temperature resistance. The rods and sheets are used to manufacture custom components like bearings, seals, insulators, and mechanical parts.

Fluoropolymer is a thermoplastic resin that has a high melting point and is stable. The FEP and PFA tubes are formed into tubes through a process known as extrusion. Heat is applied to the plastic, making it melt and become fluid. It is then pushed through a die to form the desired shape. Once the tubes are formed, they are cooled, and their sizes are trimmed. The tubes can then be used for various applications.

The features of PFA and FEP tubing include:

The functions of PFA and FEP tubing include:

There are various applications of PFA FEP tubes. These tubes are essential in many industries due to their chemical resistance, electrical properties, and high-temperature capabilities. Some of the applications include:

When purchasing PFA FEP tubes in bulk, it is essential to consider various aspects to ensure the products meet specific requirements. Here are some of the factors business owners should consider:

Consider the tube size and length. Different applications will require different sizes of PFA FEP tubing. It is important to determine the required internal and external diameters. Also, ensure the tubes are available in various wall thicknesses and lengths. Consider the temperature and the environment in which the tubes will be used. FEP and PFA have different melting points. The latter has a higher melting point than the former. Thus, it is important to consider the operating temperatures to ensure the materials are suitable.

It is also important to check the certifications and quality of the PFA FEP tube being purchased. The suppliers should provide quality certification to ensure the products are of high quality and will meet the required standards. If buying FEP tubing for medical applications, it is important to check the medical certifications. The suppliers should also provide reports to show the tubes have been tested and passed.

Another important factor to consider when buying PFA FEP tubes in bulk is the supplier's reputation. Check the reviews from previous customers to get a clear picture of what to expect. Work with a supplier who has positive reviews and has maintained a good reputation in the industry. Also, check the customer service of the supplier. A good supplier should have excellent customer service to help answer any questions and solve issues that may arise.

Lastly, consider the cost of the products. Although it is important to stick to a budget when buying, it is not advisable to settle for less just because a certain supplier has the lowest price. Work with a supplier who offers the best value and not necessarily the cheapest.

Q1: What are the standard lengths for PFA FEP tubes?

A1: There are no standard lengths for PFA FEP tubes. They can be cut to any length required by the customer. However, some manufacturers offer standard lengths of 1 meter or 3 meters.

Q2: Is it possible to print on PFA FEP tubes?

A2: Yes, it is possible to print on PFA FEP tubes using UV printing technology. This process allows for the printing of logos, texts, and other designs on the tubes' surface.

Q3: Can PFA FEP tubes be bent or shaped?

A3: PFA tubes are flexible and can be bent up to a certain degree. However, for more complex shapes, heat shrinkable FEP tubing can be used. Alternatively, rigid FEP tubes can also be used.