(11367 products available)

The polyurethane foam machine spray is a cutting-edge piece of equipment used in various industries for insulation, roofing, sealing, and filling applications. This machine is designed to mix and spray two-component materials, such as polyol and isocyanate, to create high-quality polyurethane foam. It offers excellent versatility and efficiency, making it a popular choice for businesses looking to enhance their productivity and quality of work.

There are several types of polyurethane foam spray machines available on the market, ranging from portable handheld units to large, high-capacity models for industrial use. Portable machines are ideal for small projects and areas that are hard to reach, while larger machines are suitable for extensive applications that require a higher output and coverage.

When considering a pu foam spray machine, it is essential to review its technical specifications. These machines typically have a mixing ratio ranging from 1:1 to 1:2, ensuring precise blending of materials for optimal foam quality. Moreover, they feature adjustable pressure settings, hose lengths between 30-50 feet, and heating capabilities to maintain material consistency.

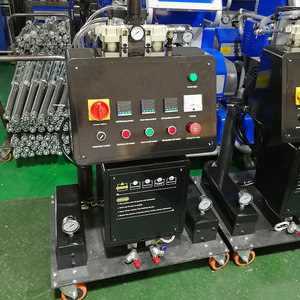

The polyurethane spray foam equipment comes equipped with advanced features to streamline the spraying process. These machines often include digital control panels for easy operation, temperature sensors for monitoring material warmth, and automatic cleaning functions for efficient maintenance. Additionally, some models offer customizable spray patterns and flow rates for tailored application.

Investing in a polyurethane spray machine offers numerous advantages for businesses. Firstly, these machines enable precise material application, reducing wastage and ensuring cost-effectiveness. Secondly, they enhance project efficiency by speeding up the spraying process and improving overall project turnaround time. Lastly, the high-quality foam produced by these machines enhances insulation and sealing properties, leading to superior results.

The pu spray machine is utilized in a wide range of scenarios across industries. It is commonly used in construction for insulating walls, roofs, and foundations, providing thermal and moisture barriers. Additionally, this machine finds applications in manufacturing for creating foam packaging, sealing products, and enhancing product durability. Its versatility makes it a valuable asset in various sectors.

When selecting a polyurethane foam spray machine for your business, consider factors such as the required output capacity, project size, and material compatibility. Choose a machine with a suitable mixing ratio and pressure range to meet your specific application needs. Additionally, opt for models with durable construction and user-friendly features for ease of use and maintenance.

To ensure the longevity and optimal performance of your polyurethane spray foam equipment, regular maintenance is crucial. Clean the machine thoroughly after each use to prevent material buildup and clogging. Inspect hoses, nozzles, and filters for wear and tear, replacing any damaged components promptly. Additionally, follow the manufacturer's guidelines for storing the machine properly when not in use.

In conclusion, the polyurethane foam machine spray is a versatile and efficient solution for businesses looking to enhance their insulation, sealing, and filling processes. With a range of advanced features, precise mixing capabilities, and application versatility, this machine offers significant advantages in terms of productivity and quality. By selecting the right machine, understanding its technical specifications, and prioritizing maintenance, businesses can maximize the benefits of polyurethane spray foam equipment in their operations.