(3254 products available)

Polyurethane sponge machinery produces sponges from polyurethane substances. These machines vary depending on the sponge produced and how the foam constituents are combined.

This machinery type is mainly applied in the production of rigid and flexible polyurethane foams. These machines use an automated process to mix and pour the foam chemicals that form the sponge when it is poured into a mold. The foam's density can be varied depending on the chemical mixture and mold used. Because of their flexibility, these foams are used in upholstery, mattresses, and insulating materials.

The Blow-in machines for polyurethane sponge machinery are primarily used for making higher density foams. This machine works by mixing chemicals and injecting air into the mixture to induce foam formation. This air interaction causes the mixture to expand more than ordinary, thereby producing a denser sponge. This machine is suitable for producing foams applied in industrial insulation and automotive seating.

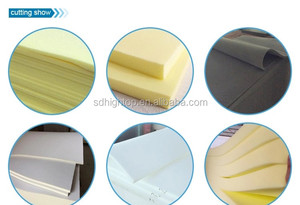

Continuous\/CF machines produce foam sheets continuously. These machines convey the foam mixture between two rolling plates that shape and cure the foam. The foam density can be easily varied by adjusting the mixture ratios or equipment speed. These machines are more effective than batch machines in producing homogeneous\/identical foam sheets. Continuous CF machines are mainly used in making foam insulation panels, mattresses, and building materials.

Batch foam machines produce sponges in batches instead of continuously. These machines mix the foam chemicals in a specified batch with heat applied. Once the batch cures, the foam is cut into parts. While these machines are less efficient, they offer better quality control with more flexible production. The sponge produced with this machine is commonly applied in furniture upholstery, car interiors, and soundproofing materials.

Polyurethane sponges are crucial in the ceramic industry, especially in handling and cleaning fragile ceramic components. They are mostly applied as padding when transporting and protecting ceramic pieces from damage. Also, the sponges are used to clean ceramic molds and dies to ensure accurate production and reduce defects. Sponges are resistant to abrasives\/chemicals and durable, making them a perfect choice for cleaning and maintaining ceramic equipment.

Polyurethane sponges are also used to clean edges on leather and textile materials. These sponges are used in textile printing for evenly applying dyes and inks to fabrics. They help absorb excess chemicals that can weaken fabrics, resulting in longer-lasting textiles. In upholstery, PU sponges are used to clean materials, and their non-abrasive texture eliminates dirt without harming delicate surfaces.

In the metal and machining works, PU sponges clean metal works while absorbing oil, grease, and metal shards. They also clean metal and sponge molds and dies to avoid metal deposits from affecting production. Moreover, they can clean machine parts and equipment to prevent contamination transfers. PU sponges are heat-resistant, thus suitable for handling hot metal pieces without harm.

Polyurethane sponges are used in the composite industry to absorb the resin and harden fiberglass and carbon fiber composites. They are also used to clean plastic molds and absorb residue from previous casts, ensuring better plastic products. Sponges are versatile and fine enough to reach small molds, making them suitable for complex tasks. Their use leads to efficient and consistent production in these industries.

Electronics use sponges to wipe off PCBs and electronic parts without scratching\/damaging them. They also absorb dioxins and other hazardous substances from the production process to protect workers. PU sponges can be grained to clean fine PCB areas for better electronic precision. These sponges will wipe residues and pollutants from PCBs and parts and leave these things spotless.

ISO 9001 certifies that the machines are made following quality management systems, ensuring the manufacturer's quality of production. ISO 14001 certificate identifies that the machine is made following an efficient environmental system to minimize its impact on the ecosystem. ISO 45001 for occupational health and safety standards ensures the machine is safe for the operator, reducing risks and injuries.

CE certification ensures that the machine complies with European standards for safety, health, and environmental protection. It particularly ensures that the machine meets the set standards for the quality and sponge production peculiarities.

Machines with this certification restrict hazardous substances such as lead and mercury, ensuring ecological safety. This certification is essential for operating in regions or markets adhering to this certification standard.

These certifications focus on machine safety features like electrical safety, temperature control, etc. They prevent risks like overheating or electrical faults and ensure that machines follow risk management practices.

ANSI\/ASQ certifications apply American standards to assure service and product quality, machine reliability, and consistency in production. These certifications boost customer confidence in machine performance.

These certifications apply to machines producing sponges and ensure they are manufactured, maintaining reliability, efficiency, and safety per international standards.

The type of machinery defined the kind of sponge produced. A pouring machine is suitable for flexible sponge production, while a blow-in machine is suitable for producing high-density sponge. Customers with specific production needs should ensure they get a machine that meets this requirement.

Select a machine with a production capacity that meets demand. In low demand, a machine with low capacity is alright, while demand requires a high-speed machine. Such machines handle large sponge orders without compromising time.

Customers should get machines that construct different densities of the foam as they might need to produce various sponges. Those with simple density production should only get machines that accommodate their current needs.

Consider the initial investments required and ongoing operating costs. Ensure the choice of machine corresponds to the allocated budget. Fintech machines might offer better returns in the long run, although they will be costly at the onset.

Customers should consider the place of installation and whether there are enough spaces for machines and spaces. These machines can be compact or possess parts, making them occupy more space than anticipated. Ensure there is an adequate space area for these machines and sufficient airflow for their performance.

Customers should consider the manufacturer's warranty and availability of assistance. Further, manufacturers with good technical help and spare availability are more effective in resolving breakdown issues that might impact operations.

A1. When operating these machines, operators should put on PPE such as gloves and goggles while following the machine manual. They should ensure proper ventilation since some chemicals used might cause harm. Always be cautious of the heat and pressure levels on the machine because they could cause burns. Only operate a machine after knowing how it works and observing all safety protocols.

A2. The machine operators should service their machines as specified by the manufacturers, although they should do it at least once yearly. Frequent maintenance helps fix possible machine problems affecting output. It helps keep machines in good condition without spending more on repairs.

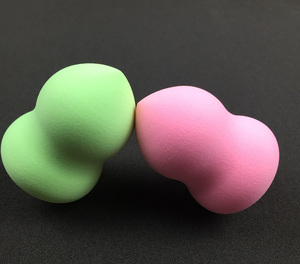

A3. The machines can produce various sponges like flexible foam for furniture and high-density foam for industrial uses. They produce continuous sponges for insulation panels and batch sponges for specialized applications. The machines can produce rigid sponges for refrigeration and packaging standards.

A4. A pour machine can handle the production of green or eco-friendly foam because it blends specific chemicals that do not harm the environment. This machine produces sponges made from renewable resources or low volatile organic compounds. Consumers' choice of a machine can accommodate the production of sustainable foam.

A5. Some defects include unequal density, which causes the sponges to be different in some areas, and improper expansion, which causes the sponge to be either compressed or oversized. A poor batch or mixture can result in a brittle sponge, while other defects cause a rubbery texture that is not wanted. Contamination can also result in sponges with pollutants in them.