(64124 products available)

A product sorting machine is used to sort products accurately according to different attributes. The following is a brief description of some common product sorting machines.

It is a machine that classifies products based on their weight. The machine uses a sensitive weighing system that can measure small variations in weight. It sorts products into predefined weight categories, ensuring that each item is accurately sorted. The weight sorting machine is commonly used in the food industry to ensure that products meet specific weight requirements. It is also used in quality control to separate products that deviate from the standard weight.

The optical sorting machine uses cameras and image processing software to analyze the appearance of products. It can sort products based on color, size, shape, or other visual characteristics. The optical sorter is highly accurate and can handle a large volume of products quickly. It is often used in the food and agricultural industries to remove defective products, foreign materials, or products that do not meet quality standards.

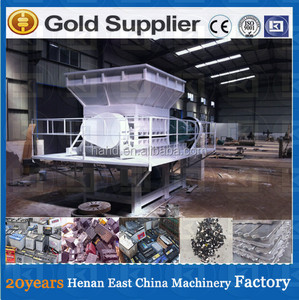

The magnetic separator sorts products based on their magnetic properties. It uses a magnetic field to attract magnetic products while allowing non-magnetic products to pass through. The magnetic separator is commonly used in the recycling industry to separate ferrous metals, such as iron and steel, from non-ferrous metals. It can also be used to remove magnetic contaminants from products to ensure product purity.

It is a machine that uses vibration and gravity to separate products into different categories. Vibratory separators are commonly used in the food processing and recycling industries. They can sort products by size, weight, or other characteristics. The vibratory separator is versatile and can be customized to meet specific sorting requirements. In addition, the vibratory separator has a compact design and occupies a small space, making it suitable for use in confined spaces.

Some general specifications that apply to most product sorting machines include the following.

Power supply: Most product sorting machines require a three-phase AC 380V power supply to function properly. Low-voltage power supply is also needed for the controller and the solenoid valve.

Power: The power of a product sorting machine will depend on the type of sorting required. It can range from a few kilowatts to tens of kilowatts.

Sorting speed: The sorting speed of the product sorting machine will depend on the type of product and the number of products that need to be sorted. It is usually measured in pieces per minute (PPM) and can vary from hundreds to thousands of pieces per minute.

Sorting accuracy: This is an important feature of a product sorting machine. Its accuracy will also depend on the type of products to be sorted. The type of sorting mechanism used will also affect the sorting accuracy of the machine.

Sorting category: Sorting category refers to the types of products that a sorting machine can categorize. It can range from fruits to industrial products. The type of sorting machine used will depend on the product category.

When it comes to product sorting machine maintenance, it is essential that the machines are maintained regularly. This will help to detect any signs of wear and tear early enough and avoid costly repairs. The first important part to maintain is the conveyors. Operators should clean the conveyors regularly to prevent the build-up of debris and dust. The guides and rails of the conveyor system should be checked periodically to ensure that they are properly aligned. The machines should also be lubricated constantly to ensure that they are functioning properly. The power sources, including the electrical components and motors, should also be checked regularly to ensure they are functioning properly. If there are any signs of damage, they should be repaired immediately to avoid extensive damage.

Product sorting machines are widely used in a variety of industries that need to sort and classify products. Here are some of the most common application scenarios for these machines:

In this industry, the product sorting machine is used to sort various kinds of food and beverages. Some of the ways in which it can be used include sorting fruits and vegetables according to their size and shape, sorting dried fruits, nuts, and candies by type, grade, or quality, and sorting seafood by size and quality. In the beverage industry, the sorting machine can be used to sort and group bottles and cans before filling and packaging.

In this industry, the product sorting machine is used to sort and classify various medical products such as tablets, capsules, and pills. It can also be used to sort and group bottles and containers before labeling and packaging. The sorting machine is also used to remove any deformed, damaged, or contaminated products to ensure that only the ones that meet the set standards proceed to the next stage of production.

In the agricultural industry, the sorting machine is used to sort and classify various agricultural products such as fruits, vegetables, and grains. It can sort these products according to size, weight, color, and quality, and remove any foreign materials or defective items.

In the logistics and warehousing industries, the sorting machine is used to sort, classify, and route packages, parcels, and products. It can be used to streamline the order fulfillment process and improve warehouse efficiency. The machine ensures that the right products are sorted to the correct destinations quickly and accurately.

In the automotive industry, the sorting machine is used to sort and classify various automotive parts and components. It can be used to sort small components such as screws, nuts, and bolts, as well as larger parts like engine components and assemblies. The sorting machine ensures that each automotive part is correctly identified and grouped for further assembly processes.

Product sorting machine buyers should choose a machine that is best suited for their specific products. Factors to consider include the shape, size, and fragility of the item. For example, fruit and vegetable sorting machines are used to sort different types of fruits and vegetables based on size, weight, color, and quality.

Another criterion to consider is the type of product. For instance, optical sorters are usually used to sort products based on visual characteristics such as color, shape, and texture. Optical sorters are used in the food and agricultural industry to sort grains, seeds, and nuts based on their quality and color. Buyers should consider their product's features, such as color and shape, before choosing an optical sorter.

Product sorting machine buyers should also consider the sorting criteria of the products. Products can be sorted based on various criteria such as size, weight, color, and quality. For instance, a fruit sorting machine can sort fruits based on size, weight, and color. Buyers should ensure that the sorting criteria of the machine align with their products.

Product sorting machine buyers should consider the capacity and speed of the machine. Buyers should ensure that the machine can meet their current and future production demands. They should also consider the machine's speed and ensure that it is fast enough to keep up with their production line.

Product sorting machine buyers should also consider the space available for the machine. They should choose a machine that can fit into their existing production line. If the machine will take up a lot of space, buyers should ensure that it is worth the investment.

Product sorting machine buyers should also consider their budget and explore different options. They should compare different machines and suppliers to get the best deal. Buyers should also read reviews from previous buyers to gain insight into the machine's performance and quality.

Q1 What are the new trends shaping the demand for product sorting machines?

A1 The product sorting machine market is being driven by two key trends: technological advancements and the growing focus on automation and efficiency. This results in an increasing demand for more advanced sorting solutions that can handle complex products with greater speed and accuracy.

Q2 What are the main factors to consider when choosing a product sorting machine?

A2 When selecting a product sorting machine, there are several essential factors to consider, including the type and volume of products that need to be sorted, the required sorting accuracy and speed, the available budget and space, and the integration compatibility with existing production and automation systems.

Q3 Can a product sorting machine be customized for unique sorting needs?

A3 Many manufacturers offer customization options to tailor product sorting machines to unique sorting requirements. This may include modifying the machine's software, adding specific sensors or sorting criteria, and adjusting the conveyor system to accommodate distinct products. Customization ensures that the sorting machine can effectively handle the specific characteristics and sorting needs of a business's products.

Q4 What are the benefits of integrating a product sorting machine into a production line?

A4 Introducing product sorting machines to production lines can improve operational efficiency, enhance product quality, and boost overall productivity. By automating the sorting process, minimizing human error, and reducing the number of damaged products, this solution streamlines operations and ensures consistent and accurate sorting. In the long run, these benefits help companies to maintain a competitive edge and meet the demands of the market.