(169 products available)

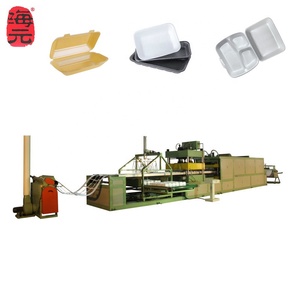

The combination of PSP foam sheet machines and the extrusion technique is widely used. The machine uses continuous extrusion to produce vast volumes of foam sheets. The sheets are light, thick, and steady. It is easy to cut, and raw materials are used to fit various shapes and sizes of the machine.

Secondly, the sheets produced by the machine are suitable for diverse applications, including packaging, insulation, and cushioning. Thirdly, foam sheets with different densities and thicknesses can be produced using an extrusion machine, which is suitable for businesses to meet the needs of different customers. Moreover, foam sheets are usually produced on a large scale by extruding machines, making them suitable for small and large enterprises.Extrusion machines for foam sheets have compact and integrated designs. As a result, it takes up little space and is easy to install in the factory. An extruding foam sheet machine suits an enterprise of any scale. High-quality foam sheets can be produced economically and efficiently to meet commercial needs.

Secondly, the vacuum forming foam machine use a different principle. A heating unit in the machine heats the foam sheet to a specific temperature. An Air Extraction Unit then pulls air or creates a vacuum in the forming box to draw the heated foam sheet down to the shape of the mold in the forming box. The cooled sheet fits the mold's shape perfectly. The machine is fully automated. So it is efficient, precise, and repeatable. A vacuum-forming machine makes it easy to mass-produce products with complex and detailed designs. It is also suitable for small prototypes.

The PSP foam printing machine combines pre-printing sheet treatment, printing, and post-printing sheet treatment into one process. First, the foam sheet is printed on directly (i.e., printed with text, graphics, etc.). Then it is post-treated (i.e., coated, laminated, or marked) using a foam printing machine for specific applications or purposes. Some machines have a printing area of 700mm x 1000mm. Moreover, a Persian-3 film and a quick look at the heating psoriasis are used in the machine, which achieves PMS quality control for all parts. The machine fits various fields, including advertising, decoration, and packaging.)

Others combine machines for greater efficiency. For example, some devices combine hot stamping and printing. Others combine a printing machine with a lamination device. Others combine a printing device with a foam cutting machine. These combination machines are economical and cost-effective for businesses.

Foam sheet width

The width of the foam sheets produced by a PSP foam sheet extruder can vary depending on the model and design of the machine. Generally, the width ranges from 800mm to 2,200mm.

Foam sheet thickness

The thickness of the foam sheets produced by a PSP foam sheet extruder can also vary depending on the machine's capability and the specific requirements of the application. It typically ranges from 2mm to 50mm.

Production capacity

The production capacity of a PSP foam sheet extruder refers to the amount of foam sheet material it can produce in a given time frame. This is typically expressed in kilograms per hour (kg/h) or pounds per hour (lbs/h). For example, some machines may have a production capacity of 100-300kg/h.

Power consumption

The power consumption of a PSP foam sheet extruder refers to the amount of electrical power it uses during operation, typically measured in kilowatts (kW) or kilowatt-hours (kWh). It depends on the size and power of the machine's motor and extruder.

Regular cleaning and disinfection

Users of PSP foam sheet extruder machines should clean and disinfect the entire machine and food production parts regularly to maintain hygiene and safety. This process should include cleaning the materials used, removing residue or pollution from the equipment, and using appropriate cleaning agents and disinfectants for thorough cleaning and disinfection.

Regular maintenance and repairs

Users should develop maintenance and repair plans for the PSP foam sheet machine, regularly checking key parts such as the engine, transmission system, foam agent adding system, etc. They should ensure that each component is in good condition and functioning correctly. If there are any issues, they should carry out timely repairs and replacements to prevent potential safety hazards and malfunctions.

Pay attention to equipment safety

Users should ensure that the equipment is safe and operating correctly. They should regularly check the electrical system and foam agent adding equipment, ensuring that the power supply and connection are secure, and there are no leakage or safety issues. Additionally, users should pay attention to the operation of the extruder and foam agent adders during use, ensuring that they are well-matched and not overloading or overstretching, to avoid safety risks.

The applications of the PSP foam sheet machine are numerous as it is used to produce foam sheets which are then utilized in various industries for different purposes.

Packaging: The primary application of the extruded polystyrene foam sheet machine is to manufacture foam sheets that will be utilized for packaging purposes, such as packaging protective cushions and packaging inserts. Foam sheets are lightweight, cushioning, and shock-absorbent, making them ideal for packaging delicate and fragile items like electronics, glassware, and products that need to be protected against impacts and shocks.

Construction: Another popular application of the foam sheet machine is to produce foam sheets that will be used as insulation sheets in the construction industry for insulating buildings, walls, and roofs, among other things. Foam sheets have a high insulation value and are lightweight, making them ideal for insulating everywhere heat transfer is required, including walls, roofs, floors, and around pipes. Foam sheets not only improve energy efficiency but also minimize heat loss and gain to make heating and cooling efforts easier.

Signage and displays: Foam sheets are used to make lightweight signage, displays, and point-of-purchase materials. The sheets can be cut, routed, and printed to create eye-catching graphics and promotional displays for retail environments.

Automotive: In the automotive industry, foam sheets are used to produce interior components, headliners, and trunk liners, to name a few. The sheets are lightweight, which assists in reducing the overall weight of vehicles and enhancing fuel efficiency.

Sports and leisure: Foam sheets are used to manufacture sports equipment, protective gear, and automotive accessories. They are commonly found in the production of goggles, swimsuits, and life jackets.

Choosing the right PSP foam sheet machine is an important task. Here's a brief guide for buyers to make an informed decision for their specific needs.

Q1: How does a PSP foam sheet machine work?

A1: The basic working principle of the PSP foam plate machine is to heat the plastic raw materials first and then stir them evenly with the foaming agent in the mixer. After that, they will be extruded into foam sheets through the extruder and the die. Finally, the foam sheets will be cooled and solidified.

Q2: Which materials are used in a PSP foam sheet machine?

A2: Common materials include Expanded Polystyrene (EPS), Polypropylene (PP), Polyethylene (PE), and Polyvinyl Chloride (PVC). Among them, Expanded Polystyrene (EPS) is a plastic material consisting of spherical particles. It is lightweight, has good thermal insulation, and is easily foamed, which is suitable for foaming technology.

Q3: What are the advantages of a PSP foam sheet machine?

A3: First, the production efficiency of the PSP foam sheet machine is high, which can produce a large quantity of foam sheets in a short time. Second, the quality of the foam sheets produced is stable, and the thickness is uniform. Third, the machines are easy to operate and can be automated.

Q4: Are there any disadvantages to using a PSP foam sheet machine?

A4: The production cost is relatively high; the energy consumption is high during the foaming process; and the machines are bulky and require a large space.