(177 products available)

Roof cutters are essential equipment for roofers and contractors to perform quality work in the specified time. It is needed because it cuts better in tough angles and produces better finishes. That is why various types of cutters are designed for the various types of roofs that exist.

Some of the roof cutter types include the following:

Remodeling roof cutters

Remodeling roof cutters are used for roof material removal. It has a narrow blade set at a right angle to the body and looks like a mop. The blade vibrates in and out of the roof. The vibration makes it easy to cut through shingles, tar paper, or any other material that needs to be cut. The cutters can be used to pull and push roofs up. This is because the head is narrow, and the user can draw it close to the roof edges to remove all the materials easily. It is mainly used to replace roofs, remove the old roofing material, and prepare a new roof for installation.

Double head roof cutter

A double head roof cutter is a construction tool that helps a builder or contractor cut different roofs and other parts. It is generally made of a special strong metal that does not break or get damaged easily. The cutter has two sharp ends that make it cut faster and smoother. This will make it easier around corners and make cuts better in hard places. It is also designed to reduce the vibration felt inside the hand when using it for a long time. Its main purpose is to cut out patterns and openings in roof materials, such as plywood or shingles, so that everything fits nicely when the roof is built.

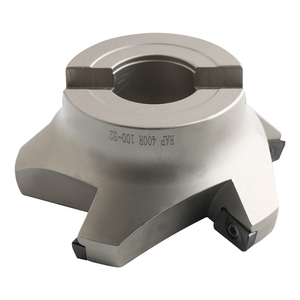

Circular roof cutters

As the name suggests, the circular roof cutter is a circular saw that is used for roof cutting. It has a toothed metal disk that is fastened to the motor, and the motor turns the tooth in a cutting manner. What makes circular roof cutters unique is that they are used to cut sheet metals and roofing materials. Unlike other cutters that cut within a specific area, the circular cutters cut materials in long and straight lines. They can also cut to a depth of 1 inch, depending on the blade adjustment.

The main function of a roof rake is to remove snow accumulation from pitched or flat roofs. It helps prevent the weight of the snow from causing structural damage to the roof. Roof rakes also assist in clearing excess water from flat roofs to prevent leaks. The lightweight, elongated design with a handle and an adjustable or fixed blade made from durable materials like aluminum or plastic allows easy and safe snow removal from hard-to-reach areas.

There are several features of the roof cutter that help in providing cutting capability.

Sharp Blades

The roof cutters have sharp blades that allow them to cut through roofing materials like shingles and plywood, making it easy to replace or fix a roof.

Smooth Operation

Roof cutters work without much shaking, so the hands don't get tired, and it's easy to make straight cuts that look good on the roof.

Compact Size

Roof cutters are small, so it's simple to bring them up ladders or in tight spaces to reach any part of a roof that needs fixing.

Lightweight

It is lightweight, so it is easy to carry and control, making cutting roofs safer and faster for workers.

Every roof cutter will have three main components designed to execute its cutting function. These components include blades, cutting motion, and body design.

Blades

The blades used for cutting roofs are different depending on the type of material being cut. For example, shingle cutters have blade designs that will ensure the blade cuts the shingle the same way scissors do to paper. Meanwhile, a circular saw roof cutter has teeth that are designed to cut through tough plywood.

Cutting motion

It can be a simple push or pull, or it can be a spinning action, depending on the cutter type. Some cutters are designed to make a vibrating motion, which is excellent for slicing through soft material.

Body design

Some roof cutters can be easily handled in tight spaces, while others are heavier and suited for charge cutting tasks.

Roof cutters are specialized tools used in various roofing and construction scenarios to cut through different roofing materials. The situations in which a roof cutter can be used will help the user know when it is appropriate to use them.

Roof installation and replacement

It is just like every other tool used in the improvement of the house. It will help during the installation and replacement of roofs. Any type, such as shingles, tiles, or metal, can be cut to the desired shape and size using a roof cutter. This will make the new roof fit perfectly when replacing the old roof.

Roofing Upgrades in the Home

For homeowners who want to upgrade their roofs, whether going for a new type of material or redesigning the roof, a roofing nailer will be needed to make these changes. In this case, a roof cutter will be used to help the homeowner accomplish the desired roofing style.

Roof repairs

In the case of a sudden emergency or small damage to a roof such as leaks, missing shingles, or broken tiles, a roof cutter is used to replace those damaged materials. This helps the roof cutter to be an important tool for the user who wants to do small repairs on a roof or contractors who have big projects.

Adding a new roof layer

Sometimes in roofing, the new material is added on top of the existing material. When doing this, a roof cutter will be needed to ensure that both layers of the old material are cut so they can easily blend with the new material that will be placed on top.

Installing roofing accessories

Roof cutters are also used to install accessories such as vents, skylights, and chimneys. Cutting openings for these installations will ensure that they fit properly and the roof integrity is maintained.

When buying or renting a roof cutter, there are several factors one need to consider in order to get the best one for the specific cutting task. These factors will also help to ensure that the cutter is efficient and does not need frequent replacements.

Type of roofing material

Consider what type of material will be cut since not all cordless roof cutters are meant for all types of material. For instance, shingle will require a cutter that can easily slice through the material, like a roofing molder. Metal roofing will, therefore, require a circular saw or shears, which will be competent enough to handle the hard material.

Power source

There are powered roof cutters, and there are manual ones. The powered one includes corded or cordless shingle cutters that are meant for prolonged use. Manual cutters include rakes and hammers, which are shorter in use but have less power in the cutting task.

Ergonomic design

Considering the job-related features of the cutter, such as weight, handle type, and grip, will ensure comfort, especially when doing the job for hours. Go for lightweight cutters to make it easy to handle. Check the handles – a good, easy, firm grip will prevent slipping and blisters.

Blade quality and adjustability

Make sure that the blades used for cutting are of good quality, long-lasting, and sharp. One should also check the type of blade used and whether it is possible to change or adjust the one in the cutter. It is because different roofing tasks will require different blades and different blade heights.

Budget

It, therefore, depends on the user’s budget since there are various affordable options and some that are premium cut through the roof. It is also necessary not to compromise quality at least to get an efficient and effective cutter for the delicate roofing job.A1: No, it actually depends on the type of job, the material used, and the working environment. Manual cutters are best for small jobs – are they easy to carry or too heavy? But don't worry, if the project is big or the material is tough, then nothing will be better than powered roofing cutters.

A2: Maintaining roof cutters will make them last longer. Cleaning the cutter after use will prevent it from being blocked – all the dust and material should be removed from it. Also, check whether the blades are sharp or need adjustments. Lastly, do storage in a dry and safe area away from children.

A3: For home roofings, a circular saw roof cutter can be used for fast and effective cutting. A cordless roof cutter is better suited for hard-to-reach areas.

A4: Cordless electric cutters are great for mobility and flexibility. This is good for projects that require movement from one location to another all the time. In situations where power is not an issue, corded cutters are better because they provide continuous energy.