(3000 products available)

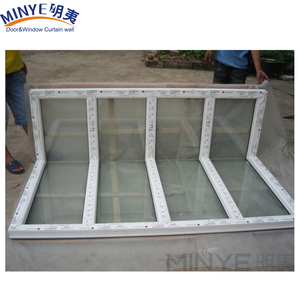

Plastic windows are an excellent choice for any home for many reasons. They are energy efficient, low maintenance, affordable, and have good sound insulation. Plastic windows are reinforced to improve their strength, functionality, and durability. The reinforcement of plastic window has different types, which include:

Window frames come in different specifications depending on the manufacturer. Popular plastic window frame options are made from PVC. These windows have lots of benefits that attract buyers. Here are some of them.

Easy to Clean

Plastic windows are easy to clean. They don't need any special cleaning products or techniques. A simple mixture of soap and water will do the trick. This makes it easy to maintain their appearance. Plastic window frames also resist the buildup of grime and mold. This means they won't need extra cleaning methods to remove stubborn dirt.

Weather Resistance

Plastic window frames are designed to withstand harsh weather conditions. They tend to last longer when exposed to extreme sunlight or heat. In addition, they resist damage from water or moisture. This means they won't get warped or rusted. Plastic window frames also resist damage from cold temperatures. Features like thermal insulation help maintain a stable indoor temperature. This reduces the effect of extreme weather on the window frame. The thermal insulation also protects the plastic window frames from rapid temperature changes. This increases their durability.

Cost-Effective

Plastic window frames are affordable. They are a good choice for people working within a strict budget. The maintenance costs of plastic window frames are also low. They are easy to clean and don't require special products or tools.

Energy Efficiency

Plastic window frames can improve energy efficiency. They have features like multi-chambered profiles that reduce heat transfer. This helps to maintain a stable indoor temperature. The thermal insulation helps to cut heating costs during winter. During summer, the windows can help keep the room cool by preventing the entry of sunlight and heat.

Versatility

Plastic window frames are versatile. They come in different styles and colors to suit any building's design. They can also fit different types of windows, such as sliding or casement windows. This allows customization to fit specific preferences.

When selecting a suitable reinforcement of plastic windows for projects, consider the following:

Project requirements

Assessing the project requirements entails understanding the specific needs and expectations of the project. This involves considering factors such as the location of the project, environmental conditions, and the level of structural integrity required. By evaluating these aspects, one can determine the essential features needed for plastic window reinforcements. For instance, in areas with high wind loads or extreme weather conditions, reinforcements that offer superior strength and durability may be necessary. Similarly, projects situated near the coast may require reinforcements resistant to corrosion due to salt exposure. Understanding project requirements allows for informed decision-making regarding the selection of reinforcements that align with the project's needs.

Material selection

Material selection is a crucial aspect of choosing plastic window reinforcements. Various materials are available, each offering unique features and benefits. Steel reinforcements are known for their high strength and durability, making them suitable for applications requiring maximum load-bearing capacity. On the other hand, fiberglass reinforcements offer a lightweight and corrosion-resistant option, making them ideal for coastal areas. Additionally, aluminum reinforcements strike a balance between strength and aesthetics, making them a popular choice for many projects. Considering the specific requirements of the project, such as load-bearing needs, environmental conditions, and desired aesthetics, can help determine the most suitable material for plastic window reinforcements.

Compatibility with window design

Compatibility with window design refers to the importance of ensuring that the chosen plastic window reinforcements integrate seamlessly with the overall window design and construction. This involves considering factors such as the size, shape, and configuration of the windows, as well as the aesthetic considerations and functional requirements. The selected reinforcements should be able to accommodate the specific window design, ensuring a proper fit and alignment. Moreover, compatibility extends beyond the physical aspects to encompass the functional integration of the reinforcements with window components such as locks, handles, and sealing systems. This ensures that the reinforcements work cohesively with other window elements, providing smooth operation, enhanced security, and effective weather sealing. A plastic window reinforcement that is compatible with the window design improves structural integrity and performance and contributes to the overall aesthetic appeal and functionality of the windows.

Installation and maintenance

Installation and maintenance are critical considerations when choosing plastic window reinforcements. The ease of installation can significantly impact the project timeline and labor costs. Reinforcements that are straightforward to install, with clear instructions and compatible with standard window fabrication processes, can save time and effort during the installation phase. Additionally, considering the long-term maintenance aspects of the reinforcements is essential. Choosing reinforcements that require minimal maintenance and are resistant to corrosion, such as stainless steel or coated materials, can reduce the need for frequent upkeep and prolong the lifespan of the reinforcements. Accessibility for cleaning, inspecting, and repairing the reinforcements is also crucial, as it ensures that they can be adequately maintained to uphold their performance and durability over time.

Replacing a reinforced plastic window can be a big job. The complexity of the job depends on whether one is replacing the whole frame or just the glass within the existing frame. Here are general guidelines for each scenario:

Tools and materials needed:

Steps to replace a plastic window with reinforcement

For full-frame replacement

Q1: Do plastic windows add value to a home?

A1: Yes, plastic windows can add value to a home. They improve the house's energy efficiency, require less maintenance, and enhance its overall appearance, which can attract potential buyers.

Q2: How long do plastic windows last?

A2: Plastic windows, particularly those made of vinyl, are designed to last for decades. However, their longevity can be influenced by factors such as installation quality, window design, and environmental conditions.

Q3: Are plastic windows suitable for all climates?

A3: Plastic windows are appropriate for all climates. They are designed to withstand extreme weather conditions. Nevertheless, choosing high-quality windows suitable for specific climatic conditions is essential.

Q4: Do plastic windows reduce noise?

A4: Plastic windows can minimize noise by providing a tight seal and being energy efficient. Windows with double or triple glazing offer additional noise insulation, making them ideal for noisy regions.

Q5: Can plastic windows be painted?

A5: Plastic windows can be painted. However, specialized paints designed for plastic are required to ensure adherence and durability. It's essential to follow the manufacturer's instructions for the best results.