(368 products available)

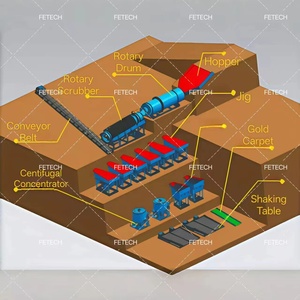

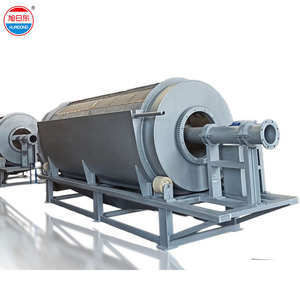

The rotating drum separator machine, also known as a rotating screen separator, comes in different types based mostly on the industry application. Here are some of the common types of rotating drum separator machines:

Rotary Screen Separator/Strainer

The rotary screen separator strainer is a common type that is applied mostly in liquid treatment industries. It works as a liquid filtration tool to separate solid contaminants from a liquid effluent. Once the feed liquid is introduced into the separator, the rotating drum moves through the incoming liquid. The contaminants float on the liquid surface, pass through the mesh, and stay in the separator drum. As the drum rotates, the drum mesh filters out solids and repels purified liquid.

Rotary Kiln

The rotary drum separator kiln is more of a heating separator machine than a filtration device. It is a cylindrical, concentric, and insulated drum that rolls along an axis that is inclined to the horizontal plane. The separator works by adding heat to substances while they roll and move in different directions. Rotary separator drums are commonly used in cement production lines to pyro-process cement raw materials. In the cement-making process, the kiln destroys the chemical bonds of the materials at very high temperatures. Rotary separators can also be used to decompose and for the thermal treatment of organic materials, such as municipal solid waste.

Rotary Air Separator

Also known as an air classifier, the rotary separator air drum works by using airflow to separate fine particles from coarse ones. It mostly processes dry materials and is very useful in the food processing industry, mineral recycling, and sand making. Rotary air classifiers can be used to separate flour, sugar, and other food products from sand, calcite, quartz, and other mineral materials. This machine can also be used to separate light plastics, rubber, and organic materials from heavier ones, such as metals and rocks.

Rotary Barrel Screens

These types of screens are set at an incline and are commonly used to segregate materials by sizes. Usually, smaller-sized materials fall through the mesh apertures while larger-sized materials move further along the mesh and exit the drum.

The separating capacity of a rotary separator in the poultry industry is typically measured in kg/hour. It can vary based on the drum's size, rotational speed, and the material being processed. For instance, a small separator might process around 1,000 to 5,000 kg/hour, while medium-sized separators could handle 10,000 to 25,000 kg/hour. Larger industrial separators may have the capacity to process up to 50,000 kg/hour or more.

Power requirements for rotary separators also differ according to their sizes and capacities. Separators that process smaller amounts of material don't require a lot of electricity and can be driven by a 2 to 5.5 kW electric motor. Medium-sized separators need electric motors with slightly more power, around 5.5 to 18.5 kW. More industrious separators that are used at an industrial scale may need motors that use 18.5 kW or more. Motors with higher power will consume more electricity, which is measured in kilowatt hours (kWh). A motor that uses 18.5 kW will consume 18.5 kW x 24 hours = 444 kWh in a single day. If it’s processing 50,000 kg of material in a day, that equals a power consumption of 0.00888 kWh per kg.

The drum diameter and length of a separator can also vary quite differently based on the separator and the material it is separating. For example, separators with a 1,000 kg/hour capacity will have a drum diameter of about 1,000 mm and a drum length of 2,000 mm, while drums that separate poultry waste with a higher capacity will be even larger - for example, 1,400 mm in diameter and 2,800 in length for a separator that can process 10,000 kg/hour.

Maintaining a rotary drum waste separator is very important in order to keep it operating efficiently, to maximise its lifespan, and to reduce the chances of failure or breakdown. Some regular maintenance tips include:

A rotating drum separator has various application industries, such as mineral processing, food processing, wastewater treatment, and chemical industries. Below are the specific uses in these industries:

When picking a drum separator for waste or any other material, there are some important factors that must be looked at closely. This includes looking at things like the quality and how durable the machine is. Questions about the separator's application and whether the separator produces quality end materials must be asked to ensure the right choice is made.

When selecting a suitable separator, the separator's function in the waste recycling process and its end use must be determined first. What kinds of materials does the drum separator intend to process? To what extent does it intend to separate materials? What kind of materials does it expect to come out from the drum separator? These are some of the questions that must be asked to ensure that the right drum separator is selected.

The quality of the building materials of the separating machine is another important thing that must be looked at closely before buying. A properly built separator will have corrosion-resistant materials or surface coatings to protect it against wear and tear and damage from corrosive materials. Such separators will have a long service life and require little to no maintenance.

The durability of the separating machine is mostly dependent on the drive system. So, in order to choose a drum separator that would last long under constant use, it's best to know and understand the drive system. Gear drives are known for their strength, and they are often used in large industrial separators. Chain drives also have good strength and can last a long time, depending on the configuration and quality. Another durable drive system is the belt drives; they are versatile, reliable, and known for their long life. Hydraulic drives are suitable for the heavy industry and large waste processing facilities. Each of these drive systems will have a different life span depending on the drum separator's quality, configuration, design, and industrial application.

A durable rotating drum separator will also have fully enclosed drives that are placed away from dust and debris. Separators that are fully enclosed will require very little maintenance, and they will not be exposed to any damage from the environment or foreign objects.

Selecting the right drum separator can be easy with the help of a few key pointers. Checking upon the drum separator supplier is also an important step in ensuring that the right choice is made. The supplier will have several types of models to choose from. So, looking at the supplier catalog is a great way to familiarize the buyer with the different available options.

Q: What is the difference between a static and a rotating drum separator?

A: The static separator is essentially a drum separator model that performs the same basic filtration process but has a cylindrical housing that remains static, or still, while the feed moves through it. A key difference between static and rotating drum separators is how the filtrate or product is drawn off and how the mesh or filter cloth is cleaned.

Q: Can a drum separator be used for oily water?

A: Induced gravity separation using a coalescing drum separator is one of the common methods used to treat oily water. A drum separator can efficiently separate dispersed oil from water when used with appropriate coalescing media.

Q: How many types of drum separators are there?

A: According to standard industrial practices, there are four types of drum separators. They are the magnetic, non-magnetic, electromagnetic, and induction drum separators.

Q: How often does the drum separator separator mesh get cleaned?

A: The frequency of cleaning the drum separator mesh can vary depending on factors such as the quality of the material being processed, the operating conditions, and the type of separator being used.