(221063 products available)

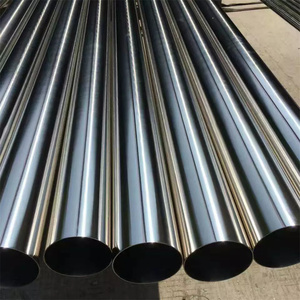

S.S tube or stainless steel tube is a long and hollow SS product with a stainless steel alloy that forms its structure. The alloy typically includes nickel and chromium, which makes the tube more resistant to corrosion. The tube goes through different manufacturing processes to form various grades and sizes. These tubes are used in applications that require components with high strength and corrosion resistance. They are used in construction, automotive, aerospace, medical devices, and many other industries.

These tubes come in different sizes, grades, and finishes depending on the application. Here are the common types:

Stainless steel pipes are long-lasting and sturdy. They have many applications in various industries because of this. Their applications include:

Stainless steel tubes have a wide range of applications across various industries and sectors due to their durability, corrosion resistance, and strength. Here are some common usage scenarios:

Construction and Infrastructure

Structural Support: Stainless steel tubes are used in construction for beams, columns, and frameworks, especially in high-rise buildings, bridges, and structures where strength and corrosion resistance are essential.

Handrails and Balustrades: Stainless steel tubes are commonly used for handrails and balustrades in buildings, staircases, escalators, and walkways due to their strength and aesthetic appeal.

Interior and Exterior Design: Stainless steel tubes are used in architectural elements such as awnings, canopies, pergolas, and decorative features in both interior and exterior design.

Automotive and Transportation

Exhaust Systems: Stainless steel tubes are used in automotive exhaust systems due to their high-temperature resistance and corrosion properties.

Chassis and Frame Components: Stainless steel tubes are used in the chassis and frame components of vehicles, motorcycles, bicycles, and other modes of transportation for strength and weight reduction.

Oil and Gas Industry

Pipelines: Stainless steel tubes are used for transporting oil, gas, water, and other fluids in pipelines due to their strength and resistance to corrosion.

Offshore Platforms: Stainless steel tubes are used in offshore platforms, rigs, and drilling equipment due to their ability to withstand harsh marine environments.

Manufacturing and Industry

Process Equipment: Stainless steel tubes are used in manufacturing facilities for process equipment such as tanks, vessels, heat exchangers, and pipes.

HVAC Systems: Stainless steel tubes are used in heating, ventilation, and air conditioning (HVAC) systems for ductwork, pipes, and fittings due to their durability and corrosion resistance.

Medical and Healthcare

Medical Devices: Stainless steel tubes are used in the manufacturing of medical devices, instruments, and implants due to their biocompatibility and sterilization.

Healthcare Facilities: Stainless steel tubes are used in healthcare facilities such as hospitals, clinics, and laboratories for plumbing, HVAC, and structural applications.

Food and Beverage Industry

Processing Equipment: Stainless steel tubes are used in food processing equipment, dairy and beverage production, and sanitary piping systems due to their food-grade properties and easy-to-clean surfaces.

Kitchen and Restaurant Applications: Stainless steel tubes are used in commercial kitchens, restaurant equipment, appliances, and utensils due to their durability and resistance to stains and odors.

Wholesale buyers can choose the right Stainless Steel Tube for their applications by considering the following factors:

Grade and Finish

The application demands. Tubes with a polished finish, such as a decorative handrail, are suitable for architectural functions. However, tubes with a matte or industrial finish are acceptable for most applications.

Type and Size

The application also determines the type of tube. The round tube is the most popular, but the structural steel tube is better for certain applications. Also, the size of the tube must be appropriate for the application. A tube that is too small or large will not work effectively. For example, a small tube is good for plumbing or electrical wiring. At the same time, a large-diameter stainless steel pipe is better for carrying water, gas, or waste materials.

Wall Thickness

Consider the pressure or load-bearing capacity required. A thicker wall tube is suitable for high-pressure applications, like hydraulic systems. Thicker wall tubes are also suitable for structural support, such as beams or columns. In contrast, a thinner wall tube is adequate for low-pressure applications, such as furniture frames or partitions.

Length

The tube must be of the correct length to meet the application's needs. Consider the cut and weld process for longer tubes to obtain the required length on-site. In contrast, shorter tubes are ready to use and require no additional processing.

Certification and Compliance

Ensure the tube meets the regulatory standards and quality certifications. This ensures the tube's safety and reliability for the intended application. Consider the tube's source and choose a reputable supplier with excellent customer service and technical support.

Q1: What are the applications of s.s tubes?

A1: S.s tubes are used in several applications. These include: construction and structural applications, automotive and transportation, manufacturing and industrial applications, oil and gas industry, medical and healthcare applications, food and beverage industry, aerospace and defense, chemical processing, water treatment, electrical and electronic applications, marine applications, sports and fitness equipment, decorative and aesthetic applications.

Q2: What are the grades of stainless steel?

A2: There are different grades of stainless steel. These include: austenitic, ferritic, duplex and martensitic. Austenitic is the most commonly used type. It has nickel and chromium. The steel is non-magnetic and it can be used in high temperatures.

Q3: How can someone distinguish between black pipe and stainless steel s.s tube?

A3: The pipes are similar in appearance but used for different applications. They carry different materials. Stainless steel s.s tubes are used to transport water, gas, and air. Stainless steel tubes are safer since they don't require a specific coating for protection against corrosion.

Q4: What is the life span of s.s tubes?

A4: These tubes have a long life span. They are durable and require little maintenance. The life span of the tubes depends on some factors. These include the type of steel grade, application, and environment.