(10599 products available)

A foam machine is a piece of equipment that makes foam. There are two main types of foam: flexible and rigid. Both types can be produced using the same basic ingredients with the same machine. Some machines can also make specialty foams used for cushioning beds and pillows.

The first type is the flexible foam machine, also known as a soft foam machine. It is commonly used to manufacture products such as chairs, mattresses, and upholstery. The functioning of this machine begins with the mixing of raw materials like polyol, isocyanate, water, and any other additives required for flexibility. Once the ingredients are added, it's whipped up into a thick foam mixture. This foam mixture expands and is then poured or gunned onto molds or furnitures where it will harden into soft foam into fully formed products.

Rigid foam machines are used to make hard plastic foams. These foams are often used for insulation purposes in buildings or for creating lightweight structural components. Examples include polystyrene, phenolic, or polyurethane foam. The functioning of rigid foam machines is similar to that of flexible foam machines. The main difference is that the chemicals used and the temperature at which they're mixed is done at high pressure in high volumes. The mixture is then expanded into a gas within the mold. Once the foams harden, they become solid and are gunned onto the area where they are needed.

Some foam machines can produce specialized types of foam. Those with a higher set of functions are usually more expensive. Latex voids are created inside the fabric using air as a blowing agent, resulting in lightweight fabric with good insulation. Latex, rubber, and PU foams are manufactured using air compressor machines that spray air into the mixture to expand and create soft voids in the material. For melamine foam, the machine will use a chemical reaction to create hard voids in the material.

Shoe-foaming machines are automatic and semi-automatic devices used in the shoe-making industry to create and apply foam, including PU foam, onto various components of footwear such as insoles, midoles, uppers, and outsoles. The machine is designed to produce foamy mixtures that provide cushioning, comfort, and structural support to shoes. This machine often comes with a stirrer that agitates the mixture and ensures the uniform application of foam.

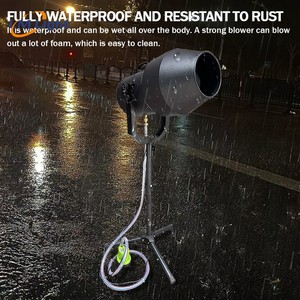

Some machines are mobile and can be moved around on different surfaces. They are often easy to transport and are used at events or for entertainment purposes. Mobile foam machines work by heating up a concentrated solution and mixing it with water and air.

The performance of a foam food machine depends on its specifications. When buying, business buyers should check these to ensure they get what their intended market needs.

Output Capacity Per Hour

A specification that shows the volume of foam the machine can produce in a specific timeframe. It's often indicated in liters or gallons per hour. The beast foam machine will have an output capacity that meets the needs of the business, considering the customers' demand and operating hours.

Foam Density Control

Foam machines often come with adjustable controls, which are critical features to ensure buyers can produce foam with different densities to meet varying applications. The machine will come with a digital panel or knobs that allow the operator to adjust the density of the foam being produced. The foam density will be measured in kg/m3 or g/cm3.

Machines that sell foam for furniture need to have programmable density settings. This means the machine will have pre-set foam densities that can be selected based on specific requirements. Moreover, it should have the flexibility to customize foam densities for specialized applications.

Mixing Speed and Power

The mixing speed and power will affect the quality and consistency of the foam produced. When buying foam food machines, business buyers should look for machines with a powerful motor and variable mixing speeds to achieve different types of foam.

Compatible Foam Chemicals

Different foam machines are compatible with specific foam chemicals or additives. When selecting a machine, chemical compatibility is critical because it affects the quality and performance of the foam produced.

The foam chemicals compatibility will be mentioned in the machine manual and specifications. It will include details such as the manufacturer's recommended foam chemicals and any specific requirements or limitations.

To ensure longevity and consistent performance, foam-making machine maintenance is essential. Research shows that about 85% of businesses can benefit from preventative maintenance. This is because it reduces the need for repairs and extends the lifespan of the equipment.

It is advisable to begin with routine cleaning. Operators should clean the machine regularly to prevent foam residue build-up. They should disassemble the parts and clean them with suitable cleaning agents. This helps maintain hygiene and prevents foam clogging.

Dealers who sell foam machines for food encourage buyers to lubricate moving parts occasionally. Lubricate the motor, bearings, and mixing paddles to reduce wear and tear from friction and extend the machine's lifespan.

Operators are advised to inspect the machine for wear and tear signs. They should check for damaged or loose components and foam production parts. Repair or replace any damaged components to avoid operational risks.

Push-based foam dispensers should be tested routinely to ensure they release foam correctly. This practice will help identify potential issues before they worsen, causing detrimental effects on the business operations.

Foam-making machines are essential in the production of cushions and mattresses. They create soft foam used for cushioning support in mattresses and pillows. They also help to manufacture car seats and forensics, among other uses.

Some of the uses of the foam machine can be on the:

When buying a foam machine for sale, buyers should get machines with different capabilities and features to suit varying business needs. Additionally, buyers should consider finding a foam machine that can handle different types of foams. For instance, a machine that can handle both polyurethane and polyethylene foams will be an ideal option for most customers. Also, buyers should invest in machines with good quality and reliable performance. Such machines will produce consistent and high-quality foam products. Buyers should also get foam machines for sale that are easy to use. In this case, they should look for machines with clear instructions, straightforward setups and user-friendly controls.

Buyers should also get foam machines for sale that come with adequate customer support and service. In this case, they should ensure the supplier offers installation guidance and after-sales service. Moreover, buyers should consider machines that are cost-effective in terms of maintenance and operating costs. They should also get machines with compatible specifications for customers planning to integrate their production processes with existing systems. Moreover, buyers should get machines for customers with varying production capacities. Some customers will be looking for machines to handle small-scale production, while others will need high-capacity machines for large-scale production. Buyers should also invest in foam machines for sale that come with safety features like emergency stops and protective enclosures. Such machines will ensure customers' employees are safe.

Additionally, when purchasing foam machines for sale, buyers should consider the energy efficiency of the machine. In this case, they should look for machines that use energy-efficient pumps and motors. Buyers should also get foam machines for sale that come with modular or customizable options. Such machines will allow customers to modify or add to their setups to meet their specific requirements. Moreover, buyers should get foam machines for sale that are compatible with the latest technology and advancements. For example, some foam machines come with automated systems which can help streamline production processes and improve accuracy. Also, buyers should choose foam machines for sale whose instructions are easy to clean and maintain.

Buyers should consider getting foam machines for sale from reputable suppliers with positive reviews. They should also take time and read reviews from previous customers to avoid disappointing purchases.

Q1: Is there a market for foam-making machines?

A1: Yes, there is a market for foam-making machines. There are many products made of foam, and those that need to make more foams will seek foam-making machines.

Q2: Can anyone use a foam machine?

A2: Yes, foam machines are safe to use and can be used by practically anyone.

Q3: How long does a foam machine last?

A3: Foam machine lifespan differs based on a manufacturer's specification, build quality, maintenance, frequency of use, and operating conditions. A good foam machine can last 10 to 15 years.