(51727 products available)

A servo 180, or more precisely, a 180-degree servo motor, is designed to provide a range of motion of up to 180 degrees. This range is standard for small and compact servo motors that are typically used in robotics, model making, and other applications where precise control of angular position is required. The limited range of motion can be advantageous for applications that do not require full rotation and where precision and accuracy within that range are essential. There are many types of servo 180 on the market, including:

Standard 180-degree servo

This is a common type of servo motor that offers precise control over its position within a range of 180 degrees. It is widely used in applications such as robotics and remote-controlled vehicles, where accurate positioning and smooth motion are required. The standard 180-degree servo is compact and durable, making it suitable for both indoor and outdoor use.

Mini 180-degree servo

The mini 180-degree servo is designed to offer the same level of precision and control as standard servos but within a smaller and more compact form factor. This makes them ideal for use in applications such as drones, where space is limited but precise control over movement is still essential. Like their larger counterparts, mini servos provide accurate positioning with a range of 180 degrees.

Digital 180-degree servo

Digital servos use advanced circuitry to provide better accuracy, faster response times, and improved torque compared to analog servos. They are ideal for high-performance applications such as competitive robotics and racing cars, where precise control and quick adjustments are essential. Digital servos also offer a wider range of motion of up to 180 degrees.

Torque servo motor

Torque servo motors are powerful devices that provide high levels of torque in a compact design. They are ideal for heavy-duty applications such as industrial automation, robotics, and CNC machinery. With their ability to handle high loads while maintaining precision, torque servo motors offer reliable performance in demanding environments.

When choosing a servo motor, consider the application, torque requirements, speed specifications, accuracy and precision, control system compatibility, power supply considerations, durability and reliability, and cost considerations.

Application

Identify the specific application for the servo motor. Determine the intended use of the servo motor, such as in robotics, automation, CNC machining, or other industrial applications. Different applications may require different types of servo motors.

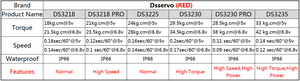

Torque requirements

Determine the torque requirements for the application. Evaluate the maximum torque needed to drive the load. Consider the static torque required to start the motion and the dynamic torque needed to maintain it. This ensures the servo motor can handle the application's torque demands.

Speed specifications

Determine the desired speed specifications. Measure the maximum speed required for the application. This includes the minimum speed needed to achieve the desired performance. Also, determine the motor's speed capabilities to ensure it meets the application's speed requirements.

Accuracy and precision

Evaluate the accuracy and precision needed for the application. This includes the position, speed, and torque control. This ensures the servo motor can achieve the desired level of control for the application.

Control system compatibility

Consider the compatibility of the control system. Determine if the servo motor is compatible with the existing control system. This includes the communication protocols and feedback mechanisms. This ensures seamless integration with the control system.

Power supply considerations

Evaluate the power supply considerations for the servo motor. Determine the voltage and current requirements of the motor. This includes the power supply's capacity and compatibility. This ensures the power supply can support the servo motor's needs.

Durability and reliability

Consider the durability and reliability of the servo motor. Assess the motor's construction and materials used. This includes the degree of protection against dust and moisture. This ensures the motor can operate reliably in different environments.

Cost considerations

Evaluate the cost considerations for the servo motor. Compare the prices of different brands and models. This includes the initial cost and the long-term maintenance and operational costs. This ensures the best value for money is obtained without compromising quality.

A 180-degree servo motor has several features and functions that make it useful in various applications. Below are some common features and designs of a typical 180-degree servo motor:

Control Circuitry:

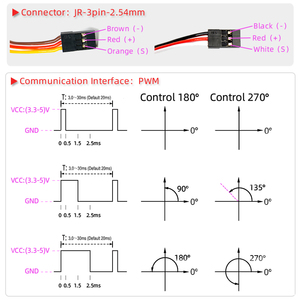

These are the internal circuits that allow the servo to process incoming signals, usually in the form of PWM (Pulse Width Modulation). The control circuitry ensures the servo motor can accurately interpret the desired position and adjust the motor to achieve that position. This helps in enhancing precision and reliability in position sensing and maintaining the motor's response to changes in the control signal.

Feedback Mechanism:

This includes potentiometers or encoders that provide the servo with information about its current position. Feedback mechanisms help maintain the accuracy of the position by correcting any errors in the motor's output. This is important in applications that require high levels of precision, such as robotics and aerial drones.

Gear Train:

The gear train helps in increasing the motor's torque and precisely controlling the servo's output shaft's movement. The gear train's design and ratio can affect the servo's speed, torque, and resolution. Servos use gear trains to reduce the speed of the motor while increasing the torque, making it suitable for heavy-load applications.

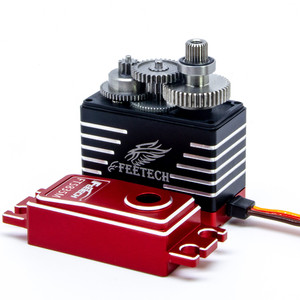

Housing:

The durable material used to make the housing protects the internal components of the servo from dust, moisture, and mechanical damage. The housing design can also affect the servo's cooling and noise levels. Servos are typically made from aluminum or plastic, which helps to shield the internal components from environmental hazards and physical impacts.

Safety and quality issues should be considered when choosing a servo motor. This is because they determine the devices' reliability, longevity, and performance.

Electrical safety

Some of the electrical safety features in servo motors are over-voltage protection, over-current protection, and short-circuit protection. Over-voltage and over-current protection can prevent damage to the motor caused by excess voltage and current. This increases the motor's life span. Short-circuit protection ensures the motor is not damaged when there is a short circuit by shutting down the power supply.

Thermal safety

Thermal protection features, such as temperature sensors and cooling systems, ensure the motor operates at the right temperature. If the motor's temperature rises significantly due to continuous heavy load or inadequate cooling, the temperature sensor will shut down the motor to avoid damage. Cooling systems, such as fans, help to dissipate heat and keep the motor cool.

Quality assurance

Quality assurance measures, such as rigorous testing, help to ensure that the servo motor meets high-quality standards. This includes testing the motor for electrical safety, mechanical safety, and environmental safety. Testing also ensures the motor performs well under different conditions and is durable. It also checks the quality of the materials used to make the motor.

Certifications

Certifications are an indication that the servo motor has been tested and meets industry standards. Some common certifications are CE, RoHS, REACH, and WEEE. CE certification shows that the motor complies with the EU's electrical safety, health, and environmental requirements. Motors with the RoHS certification comply with the restriction of hazardous substances regulation. REACH certification shows the manufacturer complies with the registration, evaluation, authorization, and restriction of chemicals regulation. WEEE certification shows the manufacturer complies with waste electrical and electronic equipment directives.

Supplier reputation

Choosing a motor from a reputable supplier is also important because they are known for their quality, reliability, and customer service. They also have a history of quality satisfaction and product quality. Buyers can also read reviews about the supplier before making the order.

Q1: What are the typical applications for a 180-degree servo motor?

A1: 180-degree servo motors are commonly used in radio-controlled devices, robotics, automation, and other applications that require precise positioning within a 180-degree range.

Q2: What are the typical applications for a 180-degree servo motor?

A2: 180-degree servo motors are commonly used in radio-controlled devices, robotics, automation, and other applications that require precise positioning within a 180-degree range.

Q3: How can buyers ensure they get a quality servo motor?

A3: To ensure the quality of the servo motor, it is recommended to obtain it from reputable manufacturers or suppliers, read reviews, and check certifications or quality assurance programs.

Q4: Are there any safety considerations when using 180-degree servo motors?

A4: Yes, some safety considerations include ensuring the motor is rated for its intended load, protecting electrical connections from moisture or damage, and following the manufacturer's installation and operating guidelines.

Q5: What are the advantages of 180-degree servos over other types of actuators?

A5: 180-degree servos offer better precision, control, and efficiency in applications requiring limited rotational movement. They are also more compact and easier to install than other types of actuators.