(14956 products available)

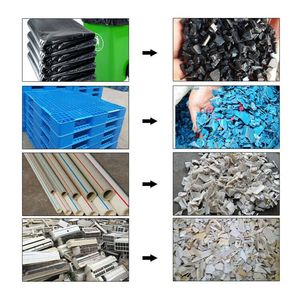

There are various types of shredders 15 based on the materials they are designed to process, the mechanism they use, and their applications.

Cylindrical Shredder

A shredder with a solid cylindrical body. The cutter shaft has circle-shaped cutters knighted on the shaft. A cylindrical shredder is usually located at the center of the plant.

Trommel Shredder

It has a rotating drum that comprises a cylindrical screen. The shredder usually changes the material shape and size through the rolling movement. A trommel shredder also has separate units like conveyors and air classifiers that will separate various kinds of materials.

Cutter Shredder

This type of shredder uses a cutter to cut through different types of shape and sizes of materials. The cutter can cut through fibers, plastics, and foam material.

Centrifugal Shredder

It works through the principle of centrifugal force. It usually impels the material from the center outwards. Some common types of centrifugal shredders include vacuum disc shredders and drum shredders.

Single-Shaft Shredder

It consists of a heavy-duty shaft with mounted knives that will cut and shred material as it rotates. A single-shaft shredder can handle a wide variety of materials.

Two-Shaft Shredder

It has two parallel rotating shafts with intermeshing cutters or blades. The shredders cut the incoming materials through a dragging and pushing motion between the blades.

Document and waste shredders have different specifications depending on the type, model, and manufacturer. However, the following are general specifications when it's possible to observe them.

Capacity

The capacity is the maximum weight of documents the machine can shred per hour. It is calculated based on several factors, including the document's weight. Generally, a shredder 15 with higher capacities tends to be more efficient.

Cut Type

Shredder machines cut documents in different ways. Some shred in strips, while others might cut the documents into confetti or particles. Strip-cut type shredders generally provide lower security compared to other shredders cut types.

Blade Count

The total number of blades can also determine how efficient and quick a shredder shreds documents. For example, shredders with less than 10 blades might be less efficient compared to those with more than 15 blades.

Power Source

A shredder machine can use electricity or be powered by a gas engine. Electrical-powered shredders are common, and they use electric motors in the range of 2 to 20 HP. Gas-powered shredders might be more applicable in situations where the documents need to be shredded in the remote area.

Noise Levels

Generally, a shredding machine is expected to produce noise levels of about 55 to 60 decibels. If a shredder produces noise levels above 70 decibels, the machine will be much louder than normal talk and might be disruptive, attracting unnecessary attentions.

The maintenance of a shredder is essential for smooth operations, longevity, and optimal performance. Here are some maintenance tips to keep in mind.

A paper shredder 15 has many applications in various industries. Below is a detailed description of some of them.

Medical facilities

An extremely secure and privacy-preserving application of document shredders can be found in medical facilities. Patient records, medical histories, and sensitive information fall under the category of protected health information (PHI), which must be confidential. Therefore, when medical institutions eliminate documents containing PHI, they employ document shredders to ensure that this information is unrecognizable and cannot be reconstructed. This practice helps protect patient privacy and comply with legal requirements.

Legal offices

Legal offices frequently utilize document shredders to dispose of documents securely. Documents such as legal briefs, contracts, client correspondence, and sensitive legal filings can contain confidential client information or privileged legal strategies. Legal professionals must ensure that these documents are permanently destroyed to protect client confidentiality and maintain attorney-client privilege. Document shredders provide a straightforward and effective way to dispose of these documents securely.

Educational consoles

Document shredders are helpful for educational institutions. Schools, colleges, and universities handle various documents that may contain sensitive information, such as student records, enrollment forms, financial information, and staff personnel files. Additionally, educational institutions must comply with regulations such as the Family Educational Rights and Privacy Act (FERPA), which mandates the secure disposal of student information. Document shredders provide a simple and effective way to shred these documents, ensuring that the information is correctly and permanently destroyed.

Government agencies

Document shredders have an important application in government agencies. Government agencies deal with many sensitive and confidential documents, such as citizen files, financial records, security-related materials, and internal documents. To maintain national and public security and protect citizen privacy, government agencies must securely destroy these documents to prevent unauthorized access and disclosure. Document shredders can shred these documents and protect the agency's credibility and integrity.

Corporate offices

Corporate offices are a typical application place for document shredders. Businesses handle many sensitive documents, such as business plans, financial statements, personnel records, client information, and trade secrets. To protect company information and maintain competitiveness, corporate offices need to shred documents containing sensitive information when disposing of them. Document shredders provide an efficient and straightforward means to shred these documents, providing information security for corporate offices.

Selecting the right document shredder for home use, especially a powerful one like the shredder 15, requires careful consideration.

Q1 What are the benefits of using an industrial shredder in a waste management system?

A1 Industrial shredders are pivotal in enhancing waste management systems. Their capacity to reduce waste volume diminutively leads to optimized storage and streamlined recycling processes. By converting diverse waste materials into smaller, more manageable pieces, shredders facilitate efficient transportation. Various industrial shredders can tackle many materials, from paper to plastics and metals. Moreover, shredders lay the groundwork for subsequent treatment procedures by preparing materials for recycling, ensuring that waste management systems function seamlessly and sustainably.

Q2 Can shredders help reduce carbon footprints?

A2 Shredders contribute significantly to sustainability by facilitating recycling and minimizing carbon footprints. Shredders reduce waste volume, making recycling operations more efficient. They ensure that recyclables are promptly reintroduced into the production cycle, thereby diminishing the requirement for virgin materials and the associated carbon emissions from extraction and processing. Furthermore, by cutting down on waste that would otherwise occupy landfills, shredders aid in reducing methane emissions—a potent greenhouse gas produced in such sites. The collective impact of shredders on recycling rates and landfill reduction plays a crucial role in combating climate change.

Q3 Which type of industrial shredder is appropriate for a specific material?

A3 Choosing the right industrial shredder is crucial for optimal material processing. When selecting a shredder, it's essential to consider the material's characteristics, such as its type, size, thickness, and any specific features like moisture content or embedded objects. Additionally, the desired output—whether the priority is a rapid throughput or achieving precision in particle size—plays a significant role. As previously mentioned, various shredders are designed to handle specific materials. Nonetheless, adaptability is key. Some machines offer versatility, allowing them to process a range of materials provided that they are configured with appropriate blades and filters.

Q4 Are industrial shredders safe to operate?

A4 Industrial shredders prioritize safety, especially in high-demand settings where numerous operators interact with the machinery daily. Beyond the standard safety features like emergency stops and guarding, many shredders now incorporate advanced safety systems such as operator detection, presence monitoring, and material handling safeguards. These active safety mechanisms routinely monitor and prevent potential hazards, ensuring a safer operational environment. It's crucial, however, that users are educated about the machine's inherent dangers. Through proper training and familiarization with the shredder's safety functions, operators can significantly mitigate risks and accidents.

Q5 How long do industrial shredders last?

A5 The lifespan of industrial shredders is influenced by several factors. First and foremost, the quality of materials and engineering during the shredder's manufacturing plays a significant role in determining its longevity. Additionally, the frequency and duration of the shredder's use—its run hours—directly impact wear and tear. Apart from the operational factors, regular maintenance is paramount. Scheduled maintenance not only ensures optimal performance but also substantially extends the machine's lifespan. When maintained correctly, many industrial shredders can operate efficiently for a decade or more, meeting the demands of various industries.