(306 products available)

A corn grinder is a machine used to break down corn into its various byproducts, such as corn flour, cornmeal, corn grits, and corn syrup. It is an essential tool in the food processing industry. Corn is native to America but is now widely used all over the world. There is a huge demand for ground corn in the market.

Cheap corn grinders are usually made from plastic and stainless steel. They are portable and can be used at home for small-scale production. Some of these models come with additional features that allow users to preprocess the corn before grinding, such as drying the maize. Others have multiple grinding options. Grinder manufacturers produce small corn grinders in three main types, including:

Wet grinders

Wet corn grinders process maize after it has been soaked in water. Corn milling companies usually use them to produce finer products. The wet maize grinder has a larger capacity and uses more power than its dry counterpart. Some models combine the grinding process with other processes, such as sifting, to produce a more refined final product. They also come with special features to handle wet corn, such as increase resistance to moisture.

Dry Grinders

Dry corn grinders process maize that has not undergone any preprocessing. They prepare cornmeal, corn flour, corn syrup, and corn grits. Unlike wet corn grinders, dry grinders are more affordable, smaller in size, and use less power. Some models can be used at home for small-scale production.

Universal Grinder

A universal grinder can grind different types of grains, such as corn, wheat, barley, and beans. It usually comes with a number of milling options to produce various final products like flour, cornmeal, and corn grits. The device has removable parts that allow users to change the grinding plates depending on the type of grains they want to grind.

Recently, some manufacturers have started to make electric corn grinders that use solar energy. They are ideal for use in areas that do not have access to electricity. Solar power corn grinders have environmentally friendly DC motors that provide adequate power for processing corn.

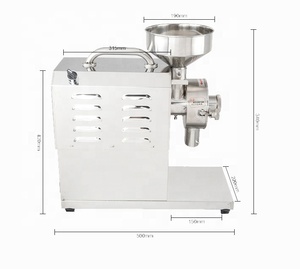

Small corn grinders are built with the inner and outer disc plate, stainless steel funnel holder, base frame, long handle, and wooden pestle. These grinder machines possess a 110V/240 power supply. The power supply and the rotational shafts with a speed of 3500rpm perform functions and provide an output of more than 50kgs in an hour. The noise level ranges between 40 to 80 decibels. The weight of an electric grinder machine may be between 30 to 40 kgs, and it will be more than 10kgs for a manual corn grinder machine.

Maintenance of corn grinders includes cleaning metallic plates and other parts of the corn grinder to remove clogs. Cleaning wipes or brushes can be used to clean the plates. Small wet cloths can be used to clean small areas. Corn grinders are diamond-shaped. Brushes are recommended for cleaning larger areas. Avoid using metal objects that may scratch the corn grinder plates. Businesses can use the following maintenance tips to keep their corn grinders in perfect working condition so that they don't break down and slow production.

Manual corn grinders can be oiled or lubricated from time to time to keep them functioning smoothly. Electric grinders with moving parts can be oiled from time to time as well, but operators should be careful and ensure they don't get exposed to oil. When cleaning corn grinders, the user should ensure no food debris is left, as it may freeze the functioning of some food items, and meat debris is not good. Create a regular cleaning schedule so that the corn grinder becomes more productive over time and its lifespan increases. Some food-grade lubricants can be used on grinder machines to prevent rust. When taking them out of storage, businesses should wipe them clean and apply food-grade lubricant oil before use.

Incorporating small cheap corn grinders into business models highlights entrepreneurship, localization, and the demand for fresh, high-quality products. These scenarios emphasize the versatility and affordability of small corn grinders, making them valuable resources for various commercial ventures.

When buying a corn grinder, several factors need to be considered. Knowing the most important features of a small corn grinder can increase sales. Choose grinders with useful features and prerequisites.

Horsepower and Milling Speed

Opting for a grinder with a minimum of 1-1.5 horsepower is ideal for achieving satisfactory milling speed and efficiency. Some grinders are available in small to medium horsepower and can have a decently fine corn meal for the customer.

Capacity and Grinding Speed

A small grinder that is portable, because it is smaller, has a slower grinding speed and capacity. In some instances, the ability to hold 5-10 pounds of corn at one time might suffice because the customer does not want a larger one, and this could be a more cost-effective choice.

Available Power Sources

A corn grinder's accessibility and power source can significantly impact its suitability for various settings and users. Hand-powered corn grinders are great for camping, while electric-powered options work best at home or in commercial settings. Solar power is great for off-the-grid situations. Knowing the power source is essential for product knowledge and ability to aid customers in knowing what will serve their needs best.

Grinder Types

Knowing the differences between a hammer mill corn grinder and a roller corn mill is essential for product knowledge. Small farms will want something small and budget-friendly but still functional. A roller can achieve a near-flour consistency and has a finer, quieter milling process. A hammer corn grinder is more robust and tackles more significant projects, even whole grains, with a harder exterior.

Storage Bin Size

An adjustable storage area is critical for product knowledge. Most bins can change from holding small to large amounts by altering the mill's settings. Some grinders have storage areas of 5-15 pounds in a bin, which is an excellent feature for customers.

Cleaning and Maintenance

Easy removal of parts and a user manual talking about how to clean and maintain the grinder is essential. Lubrication needs and any other pertinent features should be included in the manual.

Grind Size Options

While most grinders have a set of finer and coarser options, some have more advanced settings to create everything from cracked corn to flour. When flour options are available, it is excellent to understand how to mold the corn into various products.

Q1: What power does a corn grinder have?

A1: A corn grinder may have a different power depending on the model and size. For small grinders, it could be around 200 watts to 1,000 watts. Larger or industrial corn grinders have more power and can range from 5 horsepower to over 50 horsepower.

Q2: Is the corn grinder motor AC or DC?

A2: The motor food grinders use are usually alternating current motors. Some smaller models have direct current motors, and those are typically under 1,000 watts.

Q3: How many bags of corn can a grinder process in an hour?

A3: It depends on the corn grinder's size and power. Some small to medium-sized corn grinders process between 2 to 6 bags in an hour. More giant industrial grinders can process up to 30 bags or more in an hour.

Q4: How much heat does a corn grinder produce while grinding?

A4: Smaller corn grinders tend to produce more heat while grinding. It can be around 60 to 100 watts. More giant grinders are more efficient and generate around 200 to 400 watts of heat.