(539 products available)

A speed air-cooled chiller is a cooling device that uses compressed refrigerant to absorb heat from the inner part of a building. Here are some common types of speed air-cooled chillers.

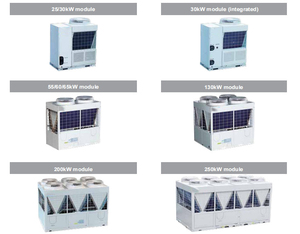

Modular chillers

Modular chillers are designed in sections that can be put together making up the final machine. The main advantage with these types of chillers is that they give room for expansion as a business grows. If more cooling is needed at some point, extra modules can easily be added on without having to replace the whole chiller system. Another interesting thing about modular chillers is how flexible they are installation-wise. Because these machines come in different pieces rather than one big chunk, it's usually easier to install them into spaces where bigger units just wouldn't fit at all. Perhaps something else worth mentioning here could be talking about servicing; since there are several smaller sections instead of just one large bit, servicing might sometimes get quicker too since technicians may find only certain parts needing attention rather than everything all together.

Scroll chillers

Scroll chillers are cooling systems commonly used in commercial buildings to control temperatures. They work by using two spirals, or scrolls, that compress refrigerants, which then absorb heat from the building. One advantage of scroll chillers is their compact size. Compared to other types of chillers, like screw or centrifugal ones, scroll units take up less space and can easily fit into tight areas. Another benefit is that they have fewer moving parts, leading to lower maintenance needs and costs over time. Because there's less physical wear inside these machines, they also tend to last longer, making them a reliable choice for businesses looking to manage indoor air quality effectively.

Low-noise chillers

Low-noise air-cooled chillers are designed to operate quietly and minimize the amount of noise they produce while functioning. This is achieved through various features such as sound enclosures, which are cabinets or boxes that completely cover the compressor and condenser coils. The purpose of these sound enclosures is to muffle or deaden any sounds coming from these parts. Another feature that helps reduce noise levels is variable-speed compressors. Unlike traditional fixed-speed motors that constantly run at full power regardless of need, variable-speed motors can adjust their pumping power according to what is actually required at the moment. By changing this compressor speed, it not only provides better temperature control but also leads to quieter operation since they do not always have to be running at maximum intensity all the time.

It is essential to know the specifications of the speed air cooler chiller before purchasing one, as this will help understand how it operates.

Chiller Capacity

The chilling capacity (in kW/ton) of a speed air-cooled chiller shows how much heat it can remove from a warm fluid per unit of time. This helps know the fundamental size of the chiller. Depending on its capacity, a chiller will suit only specific applications.

Temperature Range

Speed air-cooled chillers can typically operate within specified inlet and outlet temperature ranges. This indicates the temperatures of the fluid (often water or another coolant) that must flow through the chiller to allow it to function effectively. The temperature range must be taken into account to ensure compatibility with a given process or system.

Cooling Efficiency

The coefficient of performance (COP) or Energy Efficiency Ratio (EER) of a speed air-cooled chiller shows its cooling efficiency. A higher COP or EER indicates that the chiller consumes less energy to remove a given amount of heat, which can translate into lower operating costs.

Maintaining a high-speed air-cooled chiller is crucial for ensuring consistent performance and a long lifespan. A regular maintenance program can help identify potential problems, cut downtime, and prolong the life of the chiller.

Regular Inspection

Always visually inspect the chiller for obvious signs of wear and tear, leaks, damage, and anything unusual that may call for immediate attention.

Cleaning

Keep all coils, condensers, evaporators, and filters free from debris buildup by routinely cleaning them. An air-cooled chiller's efficiency and waste of energy can both be improved by keeping these parts clean.

Lubrication

Generally, moving parts of a chiller (fans and pumps) require constant lubrication to work smoothly and without strain.

Industry statics show that the global industrial cooling systems market was valued at $16.66 billion in 2022 and is expected to reach $20.93 billion by 2030. This indicates a rising demand globally.

The high demand shows the many uses of industrial cooling systems like the speed air cooler chiller.

Speed air chillers can be used for the following:

When considering air speed chillers for industrial applications, it is important to take into account a wide range of factors so as to ensure optimal performance, efficiency, and suitability for the specific cooling needs of the facility in question.

Cooling capacity:

Chillers are defined by their cooling capacities, which is the ability to absorb heat and remove it from the environment in terms of temperature. Hence, it is necessary to determine the amount of cooling needed for the facility or process to be chilled. Take into consideration a variety of factors, such as heat load, ambient temperature, and desired temperature.

Efficiency:

Opt for a chiller with a speed that is energy-efficient. Analyze the chiller's coefficient of performance (COP) or energy efficiency ratio (EER) to indicate its efficiency in converting energy to cooling.

Environmental considerations:

Pay attention to the type of refrigerant used in the air-cooled chiller and its impact on the environment. Consider chillers that use low-global warming potential (GWP) refrigerants to reduce environmental impact.

Noise levels:

Because of its large condenser fans and compressors, air-cooled chillers are known to be noisy. Determine the permissible noise level for the application and select a chiller with the necessary noise reduction technologies, such as sound enclosures or variable-speed fans if needed.

Maintenance and service:

Consider the maintenance and servicing requirements of the chiller. Look for models with easily accessible components for routine maintenance tasks. Determine the availability of trained service providers in the area who can handle repairs and maintenance.

Q: How Does an Air Cooled Chiller Work?

A: An air-cooled chiller works in a similar way to that of a refrigerant-based cooling system. The fundamental process is essentially the same. The air-cooled chiller starts off by absorbing heat from the liquid that needs to be cooled. This is done through a component known as an evaporator. Following this, the refrigerant that has absorbed the heat is circulated through the compressor which then increases the pressure and temperature of the refrigerant. Next, the refrigerant is sent to the condenser where the heat is released, and the refrigerant is cooled down. Finally, the evaporator cools down the water or liquid which can then be used to cool down other equipment or be circulated through a cooling system.

Q: Are Air Cooled Chilliers Efficient?

A: Air-cooled chillers while being efficient have their own drawbacks as well. They are ideal for smaller capacities or when there are limited budgets for cooling systems. However, for larger cooling needs or more energy-efficient options, water-cooled chillers with cooling towers may provide better efficiency in terms of energy usage. This is especially more applicable to industrial settings. It is worth noting that factors such as the maintenance of the system and regularly scheduled inspections can maximize a chiller's efficiency.

Q: How Long Do Air Cooled Chillers Last?

A: On average and depending on how well a machine is maintained, an air-cooled chiller can last anywhere between 10 to 15 years. Regular maintenance and inspections can ensure the machine operates smoothly without any interruptions. It is also vital to ensure that the machine is well taken care of and is appropriate for its application use to avoid any damages and prolong its life span.