(1457 products available)

Market Overview: The global spiral chiller market is poised for substantial growth, driven by increasing demand across various industrial sectors. The broader industrial cooling systems market, which includes spiral chillers, has been valued at approximately US$20.0 billion in 2023 and is projected to reach US$28.7 billion by 2030, reflecting a CAGR of 5.3% during this period, according to Global Industry Analysts. Notably, the food and beverage application segment is expected to grow at a CAGR of 5.4%, highlighting the rising need for efficient cooling solutions to preserve product quality and safety. Moreover, regions such as the U.S., estimated at $5.2 billion in 2023, and China, anticipated to grow at an impressive 8.2% CAGR, signify significant opportunities for growth in the spiral chiller market.

Industry Insights: As industries increasingly focus on energy efficiency and sustainability, consumer behavior is shifting towards advanced cooling technologies, including spiral chillers. The integration of smart features and IoT capabilities is becoming a key trend, enabling real-time monitoring and optimization of cooling processes. Major players in the market, such as Carrier and Johnson Controls, are adapting their strategies to enhance product offerings and address customer pain points related to energy consumption and operational costs. Additionally, the growing emphasis on compliance with environmental regulations is propelling the adoption of eco-friendly refrigerants and energy-efficient systems. This evolving landscape indicates that the spiral chiller market is not only expanding but also adapting to meet the demands of a more conscious consumer base.

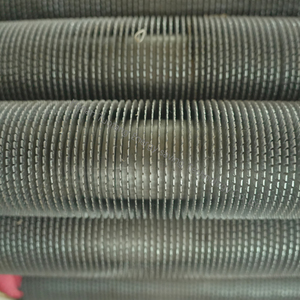

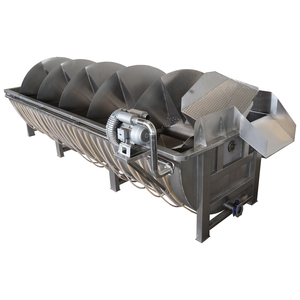

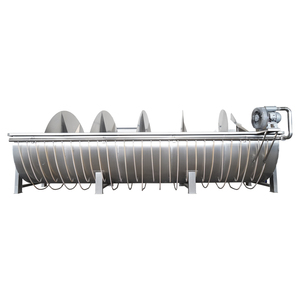

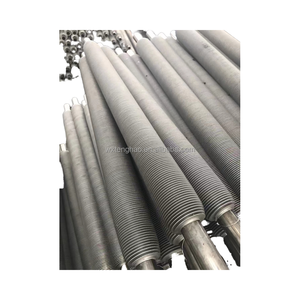

A cooling system that brings down the temperature of food and beverages items is called a chiller. Spiral chilling is a process that helps in cooling down the food product by spiral coiling refrigerants around the food item. A spiral fridge uses the same kind of technique. Spiral chillers are large machinery used in the industrial food manufacturing and processing sector to cool food items quickly by spreading them over spirally arranged surfaces at low temperatures.

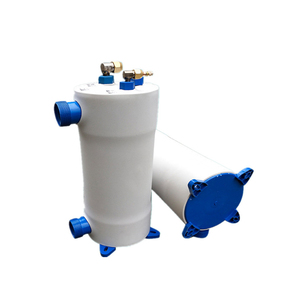

Chillers can be divided into three categories based on the type of refrigerant.

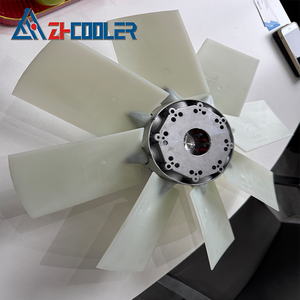

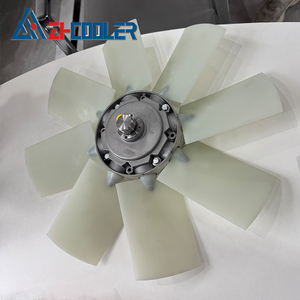

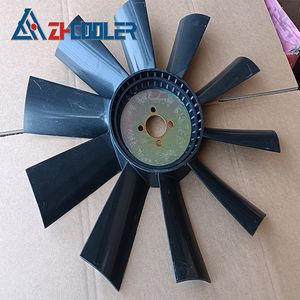

Based on the cooling method, Spiral chillers can be divided into two types:

In addition to the above, spiral chillers can also be categorized based on the airflow direction.

Capacity:

Spiral chillers have various capacities ranging from 100 kg/hr to 1500 kg/hr or even higher. The capacity is the maximum amount of food the spiral chiller can cool in one hour.

Cooling speed:

Cooling speed is the time taken by the spiral chillers to cool the hot food to a temperature between -1°C to 5°C. Generally, spiral chillers cool food at a rate of 2°C to 5°C per minute.

Temperature range:

The temperature range of spiral chillers is usually between 0°C and -40°C. This indicates the temperature at which the spiral chiller operates.

Energy consumption:

It is estimated that spiral chillers consume 2 to 15 kWh of electricity per batch of chilled food, depending on factors such as capacity, cooling speed, and refrigerant.

Runnning cost:

The operating cost of the spiral chiller is about USD 1 to 5 per hour, including electricity cost, refrigerant cost, etc.

Spiral chillers require regular maintenance to keep them working at their best. Both spiral chiller suppliers and users can follow these tips to make sure the machine works efficiently and safely.

Consider the following factors when choosing a spiral chiller:

Cooling capacity

The primary factor to consider is the machine's cooling capacity. The required cooling capacity is determined by many factors, including the type of food, the quantity, the initial temperature, and the desired final temperature.

Floor space

Because spiral chillers have a compact design, they can easily be integrated into existing production lines and require less floor space than other types of cooling systems.

Energy efficiency

It's crucial to choose an energy-efficient spiraling cooler to minimize operating costs and reduce environmental impact.

Flexibility

It can be a good idea to select a spiral fridge that can cool different types of food products, such as liquids, solids, and semi-solids, to varying shapes and sizes.

Maintenance requirements

A spiral cooler that is easy to clean and maintain will help ensure food safety and minimize downtime.

Food safety compliance

Spiral chillers should comply with food safety standards, such as HACCP, to ensure that they are designed and manufactured to minimize the risk of food contamination.

Noise level

Pay attention to the noise level produced by the spiral chiller, as some industrial facilities are located near residential areas and need to comply with local regulations on allowable noise levels.

Q1: Why is cooling rate important in a spiral chiller?

A1: The cooling rate influences food safety. Fast cooling minimizes bacterial growth. Also, rapid cooling improves food quality by maintaining the cellular structure of frozen foods.

Q2: What is the lifespan of a spiral chiller?

A2: With proper maintenance, spiral coolers can last up to 15 years or more.

Q3: Can a spiral chiller be modified to cool different types of products?

A3: Yes, some spirals can be modified. New evaporators may be added or existing ones rearranged to improve the performance of the spiral chiller. However, before any modification, consult the manufacturer to ensure compatibility and safety.

Q4: What are the most recent developments in spiral chilling technology?

A4: Some spirals have automated cleaning systems. Others have hybrid refrigeration that combines spiral chillers with freezing to reduce energy use during peak cooling times.