(180 products available)

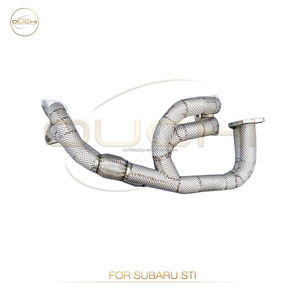

Top Mount STI Headers:

Top mount sti header are positioned above the engine, making them suitable for vehicles with engine layouts that allow this configuration. This header style is often seen in Subaru WRX models. Top mount headers are known for their ability to reduce turbo lag and improve throttle response, making them ideal for performance-oriented driving.

Equal-Length Headers:

Equal-length headers are designed to ensure that each exhaust pipe leading away from the engine's cylinders is the same length. This design minimizes exhaust gas turbulence, reduces back pressure, and optimizes the scavenging effect. As a result, equal-length headers improve engine efficiency, increase horsepower, and provide a smoother exhaust note. These headers are commonly used in racing and high-performance applications where maximizing engine output is critical.

Unequal Length Headers:

Unequal-length headers feature exhaust pipes of varying lengths. This design creates a specific firing order and exhaust pulse pattern that can enhance low-end torque. Unequal-length headers are often found in factory-built performance vehicles and are favored by enthusiasts who prioritize strong low-end power delivery. While unequal-length headers may not provide the same level of peak horsepower gains as equal-length headers, they excel in applications requiring robust low-end performance.

Stainless Steel Headers:

Stainless steel headers are constructed from high-grade stainless steel alloys. This material choice provides excellent corrosion resistance, making these headers suitable for various driving conditions and environments. Stainless steel headers offer durability and longevity, ensuring they can withstand the high temperatures and stresses of exhaust gas flow. Additionally, the smooth internal surfaces of stainless steel headers minimize exhaust turbulence, contributing to improved engine performance and efficiency.

Long Tube Headers:

Long tube headers are characterized by their extended primary pipes that lead further down the vehicle's chassis. This design maximizes exhaust scavenging, resulting in significant improvements in mid-range and high-end horsepower. Long tube headers are often used in performance applications where maximizing engine output is a priority. However, due to their extended length, long tube headers may require modifications to the vehicle's exhaust system.

Shorty Headers:

Shorty headers have shorter primary pipes that exit the engine bay relatively quickly. This design leads to increased back pressure compared to long tube headers. Shorty headers are typically easier to install and may not require significant exhaust system modifications. As a result, shorty headers are often chosen for applications prioritizing cost-effectiveness and improved engine response without the need for extensive exhaust system changes.

Material

STI headers come in three main types, and the material used in each type is different. There are headers made from stainless steel, cast iron, and carbon steel. Each type has its own advantages. For instance, stainless steel headers have great resistance to corrosion and rusting. They are also very durable and strong.

Type of Coating

Some headers have a special type of coating on the surface. This is done to improve the appearance of the header and also offer protection. One of the common types of coating is the ceramic coating. It is done to protect the headers from high temperatures and corrosion.

Size

STI headers come in different sizes. The size of a header is determined by the size of the exhaust pipes. The exhaust pipes are measured in inches. Most headers have pipe sizes that range from 1.5 to 2.5 inches in diameter. This means the pipes will measure 1.5 to 2.5 inches across in round.

Type

There are different types of STI headers. Each type is designed to suit a particular model of Subaru vehicle. The most common types are unequal length and equal length headers. The headers are also designed for specific purposes. For instance, some headers are designed for racing.

Fitment

Different models of Subaru vehicles have headers that are designed to fit perfectly in the exhaust system. This is important because it helps eliminate any potential issues. For instance, it helps prevent any leaks or cracks that may occur in the exhaust system due to improper fitment.

Maintaining STI headers is important to keep them in good condition and functioning well. Here are some maintenance practices.

Choosing the right STi headers for a business can be a challenging task. Here are some ideas to consider:

Many Subaru headers are available for DIY replacement. Nonetheless, the process is a bit complicated and requires mechanical knowledge to execute it successfully. Below is a step-by-step guide on how to replace an STI header:

Q: Are STI headers worth the money?

A: The worth of STI headers depends on various factors. They are generally more expensive than standard headers because they are made of high-quality materials and designed to improve the vehicle's performance. If the user is looking to improve the performance of their vehicle, they are worth the money.

Q: Do STI headers fit all vehicles?

A: No, STI headers are not made to fit all vehicles. They are designed to fit specific makes and models. It is important to verify that the headers will fit the vehicle before purchasing them.

Q: How long do STI headers last?

A: The longevity of STI headers can vary depending on several factors, such as the type of material they are made from, the level of maintenance, and the driving conditions. Generally, they are designed to be durable and can last a long time with proper maintenance.

Q: Do STI headers require maintenance?

A: Yes, STI headers require some level of maintenance to ensure they function properly and last a long time. Users should routinely check them for any signs of damage or wear and address any issues promptly. Additionally, keeping them clean is important, especially in areas with high levels of dirt or debris.