(8257 products available)

T8 heatsinks are crucial for maintaining optimal temperatures in LED lighting applications. These components dissipate heat away from the LED lights, thus preventing overheating and ensuring their functionality. T8 LED tubing is a popular choice among businesses due to its versatility and energy efficiency. Understanding the different types of T8 heatsinks allows buyers to make informed decisions that meet their specific needs. The types of T8 heatsinks can be classified as follows:

Aluminum Extrusion Heatsink

The aluminum extrusion heatsink is one of the most common types. It is cost-effective and lightweight and offers a good thermal performance. This heatsink is made of aluminum, which is extruded to form various designs and profiles. The design can be customized to fit specific LED requirements. The aluminum extrusion heatsink is easy to manufacture and suitable for a wide range of applications.

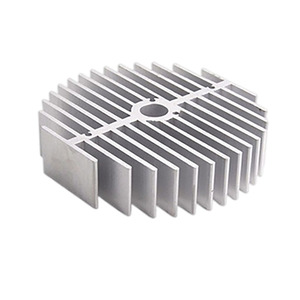

Aluminum Fin Heatsink

This heatsink is designed with multiple thin aluminum fins. The fins increase the surface area for heat dissipation. As a result, this design allows for efficient passive cooling. The aluminum fin heatsink is mounted directly onto the LED light source. It is ideal for applications with limited space and low thermal resistance requirements.

Copper Heatsink

Copper is known for its superior thermal conductivity. The copper heatsink is designed specifically to dissipate heat from high-power LED sources. It can be fabricated into different designs, such as extrusion or machined. The copper heatsink offers excellent performance in high-temperature environments.

Active Cooling Heatsink

This heatsink is designed with an integrated fan or blower. The active cooling heatsink provides forced air circulation. This mechanism leads to more efficient heat dissipation. The cooling system reduces the LED temperature in high-power or high-density lighting applications. However, it requires a power source and may produce noise during operation.

Hybrid Heatsink

The hybrid heatsink combines aluminum and copper. It is designed for applications that require a balance between cost and thermal performance. The heatsink can be lightweight and offer good heat dissipation. It can also be optimized for specific LED configurations. The hybrid heatsink is versatile and suitable for various T8 LED applications.

LED light t8 tube heatsinks are popular for their high performance, durability and versatility. Here are the key features and functions of LED tube light heatsink:

Efficient Heat Dissipation

The primary function of an LED heatsink is to dissipate heat away from the LED components. This is critical to maintaining their optimal performance and longevity. The heat dissipation is caused by the conduction and convection through the aluminum material. This allows the LEDs to operate at lower temperatures.

Improved LED Efficiency

Lowering the LED's operating temperature improves its efficiency. The LEDs emit more light per watt of power consumed. This results in brighter lights and energy savings.

Extended Lifespan of LED Lights

Efficient heat dissipation ensures the LEDs do not suffer from thermal degradation. As a result, it improves the tube's overall lifespan and reduces maintenance costs.

Robust and Lightweight Design

Most tube lights' heatsinks are made of aluminum due to their lightweight and robust properties. Aluminum is resistant to rust and corrosion, making the T8 heatsink durable and long-lasting. Aluminum can be extruded into different shapes and sizes to fit various design requirements.

Compatibility with Standard T8 Tubes

These heatsinks are designed for T8 standard fluorescent tubes. They are compatible with most T8 LED light strips in the market. This feature enables easy retrofitting of existing T8 fluorescent tube fixtures to LED technology, thus improving energy efficiency.

Passive Cooling System

T8 LED tube heatsink is designed for passive cooling. It eliminates the need for fans or other active cooling components. For instance, the fins create a larger surface area to promote heat dissipation through natural convection.

Customizable Length and Diameter

The heatsinks can be modified to fit various tube lengths and diameters. This feature provides manufacturers with design flexibility to create LED tubes of different sizes and specifications.

LED light bars are used in various industries and applications. Some of the common usage scenarios include:

Automotive Industry

T8 LED light bars are commonly used as truck and car headlights, taillights, brake lights, fog lights, and off-road lighting. The LED bars improve visibility and safety on the roads.

Construction Industry

Companies in the construction industry use T8 LED light bars for outdoor lighting. The bars illuminate construction sites, roads, parking lots, and other areas. They are also used for task lighting and general lighting in construction equipment and vehicles.

Recreational Vehicles

T8 LED light bars are used in ATVs, UTVs, motorcycles, bicycles, snowmobiles, and other recreational vehicles for lighting. The LED bars enhance visibility and safety during recreational activities.

Commercial Vehicles

These LED light bars are used in commercial vehicles like vans, buses, trailers, and delivery trucks for lighting. The bars improve visibility and safety while transporting goods and people.

Emergency Vehicles

T8 LED light bars are used in police cars, ambulances, fire trucks, and other emergency vehicles. The bars ensure visibility and safety in emergencies.

Marine Industry

T8 LED light bars are widely used in boats, ships, yachts, and other watercraft. The bars improve visibility and safety while navigating the waters.

Agriculture Industry

Farm machinery like tractors, harvesters, and other equipment are fitted with T8 LED light bars for lighting. The bars enhance visibility and safety when working on farms.

Sports and Entertainment

These LED light bars are used in outdoor sports facilities, stadiums, arenas, and other locations for lighting. The bars improve visibility during sporting events held at night.

Warehouses and Logistics

T8 LED light bars are used in forklifts, pallet jacks, and other material handling equipment for lighting. The bars enhance visibility and safety when moving goods in warehouses and logistics centers.

Security and Surveillance

LED light bars illuminate security perimeters, surveillance areas, and other locations. They enhance visibility and monitoring of security and surveillance areas.

When looking at various T8 LED tube lights for sale, it is important to consider various factors to ensure the right product is purchased. Here are some key points to keep in mind:

Compatibility with Existing Fixtures

One of the major factors to consider when buying T8 LED tubes in bulk is whether the tube is compatible with the existing hardware. If a customer is looking to replace their existing T8 fluorescent tubes, then a retrofit LED tube would be appropriate. However, if a customer is looking to replace an older hardware system entirely, then a T8 tube that is not dependent on ballast would be more appropriate.

Direction of Light

Another important factor to consider is the direction of the light. Some tubes, like the T8 LED tube double-sided light, are more appropriate for certain settings than others. For example, double-headed tubes are better for areas that need light in all directions, like parking lots. In contrast, single-headed tubes are more appropriate for use in fixtures that already have a space for a single tube to fit.

Color Temperature and CRI

When buying T8 LED tubes in bulk, it is essential to consider the color temperature of the light to ensure that it is appropriate for the space where it will be installed. Color temperature indicates whether the light will have a cool or a warm hue. In contrast, CRI indicates how the light affects the appearance of color, with a higher index meaning that the light will make colors appear more natural.

Heat Dissipation

The other factor to consider is the way the tube dissipates heat. Because fluorescent tubes produce a lot of heat while in operation, it is important to have a good way to get rid of it to keep the tubes from overheating. An effective heat sink is essential for not only the performance of the tube but also its safety and longevity.

Q1: Are there LED options for T8 tube lights?

A1: Yes, there are T8 LED tubes that come with integrated LED T8 tube light fixtures. These options eliminate the need for a ballast and are known for their energy efficiency and longer lifespan.

Q2: What are the common lengths for T8 fluorescent tubes?

A2: The standard length for T8 tubes is 48 inches. However, there are also 2-foot T8 tubes and other non-standard sizes like 36-inch tubes and 60-inch tubes.

Q3: What does a T8 heatsink do?

A3: A T8 heatsink is responsible for dissipating the heat that is generated by the fluorescent or LED tubes during operation. It helps maintain optimal temperature levels for the lights and ensures efficient performance and longevity.

Q4: What is the difference between T5 and T8 tubes?

A4: The main difference between T5 and T8 tubes is their diameter. T5 tubes have a diameter of 5/8 inches, while T8 tubes have a diameter of 1 inch. T5 tubes are more efficient and brighter than T8, but T8 tubes are easier to install and maintain.

Q5: What are the common problems with T8 fluorescent tubes?

A5: Common problems with T8 fluorescent tubes include flickering, buzzing noise, and poor lighting. These problems are often caused by a faulty ballast, old tube lights, or improper installation. They can also be due to moisture and dirt buildup.