(356 products available)

Construction enterprises heavily rely on tci rock cutter because these machines bring specialized capabilities to stone-based and hard-material operations throughout the industry. These machines achieve precise stone surface outcomes by performing cutting functions, shaping operations, and finishing tasks. The diverse range of capabilities showcased by tci rock cutter along with their technological development makes them vital equipment that professionals choose for boosting productivity and precise stone processing operations. The machines provide different operational options through multiple configurations which allow them to work optimally for various construction needs.

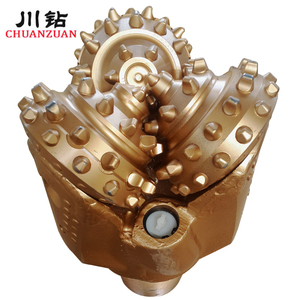

The market contains different types of tci rock cutter machines that have specialized features for particular operational needs. Three common stone processing machines available in the market include bridge saws, CNC routers, and edge polishers. Bridge saws function effectively at cutting significant stone slabs through their equipped diamond-tipped blade systems which deliver precise and clean cuts. A CNC router operates as a versatile machine that excels at creating complex patterns during stone surface engravings, particularly for producing intricate stone artwork. Edge polishers specialize in stone slab edge finishing through a process which produces polished surfaces to enhance their visual appearance. The different types of tci rock cutter exist to handle unique stone processing applications while providing perfect integration to specific stone industry operations.

Each tci rock cutter contains functionalities that enhance the efficiency of stone processing operations. These machines provide exact specifications for stone cutting and both shaping and polishing operations for various construction tasks. The combination of automated controls together with variable speed settings and advanced safety features improves operational efficiency and user convenience during the stone processing workflow. The automation system enables users to set exact cutting parameters through its control features alongside multi-speed controls that adapt to materials during processing. Safety mechanisms possess two key features which include emergency stops and protective guards which guarantee user security during equipment operation. tci rock cutter components possess durable construction together with reliability characteristics that enable their utilization in challenging environments for prolonged periods.

The construction of tci rock cutter requires high-quality components for maintaining performance standards and boosting lifespan. The machine requires essential parts composed of steel frames combined with diamond blades and electronic controls to operate effectively. The steel frame structure adds stability through its design characteristics and diamond blades allow precise cutting of hard materials. The electronic control system enables automated processing with efficient operation and better measurement accuracy. Manufacturers can create tci rock cutter products specifically designed for different working needs by selecting appropriate materials which increase machine operational quality and durability. Innovation in material science receives advancements from technological developments which enhance the sustainability and performance characteristics of these machines.

For maximum benefits of tci rock cutter users must understand both its functioning abilities together with its constraints. Machine selection for optimal performance should match the extent and type of stone processing work at hand. The machine must receive proper maintenance and calibration because this practice helps prevent operational issues and promotes better productivity. Safety features should be used to safeguard operators while also reducing potential risks that occur during operations. Construction projects should analyze how to integrate tci rock cutter with additional equipment to create more streamlined processes that lead to better efficiency. The desired performance outcomes and equipment longevity depend heavily on both training people correctly and making them follow operational procedures. Equipment performance remains at its maximum level and operational time stays consistent by performing scheduled maintenance and replacing retiring components on time.

Various factors need consideration when selecting tci rock cutter for construction work to guarantee both peak performance and maximum operational effectiveness. Begin the performance assessment by determining both the project application and the processed stone type. The design of different stone processing machines enables work on specific materials including granite marble alongside limestone because each type needs its own particular cutting method. The chosen machine must correspond to the dimensions of an ongoing construction task. A machine's capacity to handle workload determines the equipment selection for big projects yet small businesses need smaller-scale products.

Another essential factor to consider when choosing tci rock cutter involves the selection of integrated technological features. Modern machines contain innovative automation features with automated control systems which provide users with better precision and easy usability. CNC technology and digital measurement tools and programmable settings integrated with the machines enable users to create challenging designs and complex patterns. A technology selection should correspond both to project complexity and the expected customization level. The evaluation must examine both how well the machine will endure wear and tear and the maintenance needs since they determine total operational costs and machine reliability.

Users must prioritize safety during their operation of tci rock cutter. All operation personnel must receive training about safety protocols which embraces protective equipment usage and operational guidelines requirements. Protective guards together with emergency stop functions found on machines serve to decrease operational risks. The machinery requires regular maintenance checks to verify its working safety conditions persist.

Technological advancements have significantly improved the efficiency of tci rock cutter. Features like CNC technology enable precise control over cutting and shaping processes, reducing waste and enhancing productivity. Automation reduces manual intervention, speeding up operations and minimizing errors. Staying updated with the latest technological innovations can lead to better project outcomes.

Yes, many manufacturers offer customization options for tci rock cutter. Customization can include modifications to machine size, capacity, and technological features to better suit specific project requirements. This flexibility allows for tailored solutions that align with unique construction challenges and objectives, improving overall efficiency and results.

The longevity of tci rock cutter is influenced by several factors, including the quality of materials used in construction, regular maintenance, and adherence to operational guidelines. High-quality components like diamond blades and robust steel frames contribute to durability. Routine inspections and timely replacement of worn parts can extend the machine's lifespan and maintain optimal performance.

Environmental considerations can be integrated into the use of tci rock cutter by selecting machines that minimize energy consumption and reduce waste. Using water recycling systems during stone cutting and polishing can conserve resources. Additionally, opting for machines designed to produce less dust and emissions can help mitigate environmental impact, promoting sustainable construction practices.