Types of Tiling Lath

A tiling lath is a metal or wooden strip that serves as a base for plaster or tiles. It is fixed onto a framework, usually made of wood or metal, which is then attached to a wall or ceiling. Once the tiles or plaster are ready, they can be fixed onto the lath using nails, screws, or adhesives. Laths are an essential part of any tiling job as they provide the necessary support and structure for the tiles or plaster to be fixed securely.

There are different types of lath for tiling depending on the material, and they are as follows:

- Wooden lath: These are thin strips of wood, usually between 1/4 and 3/8 inches thick. They are also known as slats. Wooden laths are traditionally used in plastering and are nailed to a wooden frame. They can also be used to create a framework for hanging plaster in curved or irregular spaces. One of the advantages of wooden lath is that it is easy to work with and less prone to damage. However, it has some disadvantages, such as being prone to warping and requiring more time to install compared to other types of lath.

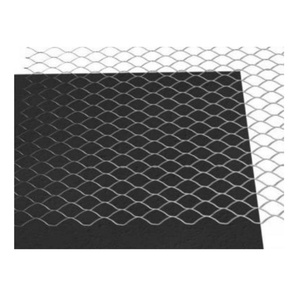

- Metal lath: This is a more common type of lath used for plastering and is made of galvanized steel or aluminum. It is relatively thin (usually around 25 gauge) and has a mesh pattern to allow the plaster to grip and cure effectively. Metal lath comes in sheets that are attached to a frame using screws. It is more durable and provides better support for heavier plaster applications. Metal lath also has the advantage of being resistant to moisture and fire. However, it is less flexible and can be more expensive than other lath types.

- Cardboard lath: As the name suggests, this lath is made from cardboard. It is used mainly for interior plastering applications. It is lightweight and easy to install and can be used for both straight and curved surfaces. Cardboard lath is also more affordable than metal or wood lath. However, it is less durable and cannot be used in high-moisture areas.

- Gypsum lath: This is a type of lath made of gypsum plaster sandwiched between two sheets of heavy paper. It is also known as rock lath and is used for interior plastering applications. Gypsum lath can be used to create fire-resistant walls and ceilings and is easy to install and provide a smooth, stable surface for plastering. However, it is heavy and cannot be used in high-moisture areas.

Functions and features of tiling lath

Tiling laths are timber strips with several features that make them suitable for fixing tiles on walls. Their functions include:

- Support: The lath provides a solid base for fixing tiles. The closely spaced lath allows even weight distribution of the tiles and prevents the tiles from cracking due to excess weight. Tiling laths also prevent water damage to the wall by providing a space behind the tiles that allows moisture to escape and dry, preventing mold growth.

- Alignment: Tiling laths ensure the tiles are aligned correctly. The straight lath serves as a guide for tilers to fix tiles in a straight line. The laths are fixed using a level to ensure the tiles are also level. This ensures the final tiled surface is straight and level.

- Ventilation: The gap behind the tiled surface created by the lath allows for airflow and ventilation. This ventilation regulates temperature, especially in bathrooms and kitchens, and prevents the buildup of moisture that causes mold growth.

- Material: The laths are usually made of timber, which is lightweight, easily cut and fixed, and cost-effective. Some laths are made of metal, which is more durable and provides better moisture resistance. Gypsum board laths are lightweight, easy to install, and provide a smooth surface for tile adhesion.

- Surface area: The flat surface of the lath provides excellent adhesion for tile mortar, ensuring the tiles are firmly fixed. The spacing between the laths allows the mortar to grip the tiles and dry effectively.

- Moisture resistance: Some laths are treated with chemicals to prevent rot and warping, which is essential in areas with high moisture levels like bathrooms and kitchens. This treatment increases the laths' lifespan and maintains structural integrity.

- Compatibility: Tiling laths can be used with different types of tiles, including ceramic, porcelain, and natural stone tiles. This versatility makes laths suitable for various tiling projects.

- Ease of installation: Tiling laths are easy to install using basic tools. They can be cut to size and fixed to walls using screws or nails, making tiling projects straightforward.

- Durability: With proper installation, tiling laths can last for many years. They provide a solid and stable base for tiles, ensuring that the tiled surface remains intact.

Scenarios of Tiling Lath

As mentioned above, lath is a thin strip of wood used as a foundation for plaster or tiles. Tiling lath is used in different scenarios, including the following:

- Building and construction: Construction companies use tiling lath in the construction of walls and roofs, providing a solid base for plaster and tiles. Lath is also used in bridges, decks, and piers. It helps distribute weight evenly and provides structural support. Tiling lath is also used in the construction of wooden frame houses. It is used as a base for plaster and tiles in houses with wooden frames.

- Remodelling: Lath is used in remodelling old houses with plaster and wooden frames. It provides a base for new plaster or tiles. Tiling lath is also used in modern homes, providing a base for plaster or tiles in renovated areas.

- Road and railway construction: Lath is used in the construction of roads and railways. It helps distribute weight evenly and provides structural support in areas such as bridges and tunnels. Tiling lath is also used in the maintenance of roads and railway infrastructure. It provides a base for plaster in the repair of cracks and potholes.

- Furniture making: Lath is used in the construction of chairs, tables, and cabinets. It is also used in the making of modern furniture, providing a base for plaster or tiles in chair and table surfaces. Tiling lath is also used in the repair of wooden frame furniture, providing a base for tiles or plaster in repaired areas.

- Decorative applications: Lath is used in the construction of decorative wooden frames. It is also used in the construction of ceilings, providing a base for plaster or tiles in vaulted and coffered ceilings. Tiling lath is also used in the decoration of walls, providing a base for plaster or tiles in ornate patterns and designs.

How to Choose Tiling Lath

Choosing the right lath for tiles involves considering several factors. Here are some of them:

-

Assess the Project Requirements

The first step is to evaluate the specific requirements of the project. This involves determining the type and location of tiles to be installed. For example, is it floor tiles or wall tiles? Are they going to be installed in high-moisture areas like showers and bathrooms? Understanding these factors will help in selecting a lath that meets the needs of the particular project.

-

Consider the Tile Type

Different types of tiles have unique requirements. Heavy natural stone tiles usually need a strong and stable backing like cement board lath. On the other hand, lighter ceramic and porcelain tiles can be supported by gypsum lath or cement board. Therefore, it is important to consider the type of tiles to be used to choose an appropriate lath.

-

Evaluate Moisture Resistance

Moisture-resistant laths like cement board are crucial in areas with high humidity and moisture. This includes places like kitchen backsplashes and bathroom walls. Such laths prevent mold growth and ensure the longevity of the tiled surface.

-

Check Compatibility with Framing

Laths should be compatible with the framing material used in the construction. For wooden frames, cement board or gypsum lath can be used. On the other hand, steel frames work best with product lath. This ensures ease of installation and structural integrity.

-

Installation Method

Different laths have unique methods of installation. For instance, gypsum lath is nailed or screwed in place, while cement board is screwed directly onto the framing. Understanding the installation methods will help in choosing a lath suitable for the skill level of the person carrying out the task.

-

Evaluate Cost and Availability

Laths for tiles come in different price ranges. It is important to evaluate their cost and select one that falls within budget. Additionally, consider the availability of the lath in the local area to ensure it can be easily obtained.

-

Consult with Professionals

Before making a final decision, it does not hurt to consult with professionals. This includes contractors and tile manufacturers. They provide valuable insights and recommendations based on experience and expertise.

tiling lath Q & A

Q1: What is the purpose of a lath in tiling?

A1: The lath provides a stable base for the adhesive to grip onto when securing tiles to walls. It prevents flexing or movement that could crack tiles.

Q2: Why not just use plywood instead of lath?

A2: Plywood can trap moisture and cause mold or mildew. Lath is made from thin slats of wood that allow mortar to dry fully and provides the perfect amount of grip for tile adhesive.

Q3: How does one prepare walls for tiling lath?

A3: Ensure walls are clean, level, and free from moisture. If using gypsum board, make sure it is not damaged and securely fastened to the wall studs.

Q4: What is the maximum size of tiles that can be used with lath?

A4: Lath can support up to 18-inch square tiles. For larger tiles, backer board is recommended as it provides more stability than lath.

Q5: Can lath be used for floor tiling?

A5: No, lath does not provide the strength or stability needed for floor surfaces that will hold weight. Use backer boards or plywood for floor tiling projects.

Popularity Trends

The web search volume for the keyword "tiling lath" in the Construction & Building Machinery category shows an average monthly search of 40, with a significant 100% increase over the last three months. Despite this spike, the one-year change remains at 0%, indicating stability in the long term.

Analyzing the monthly data reveals a fluctuating trend in web search volume for "tiling lath." From December 2023 to November 2024, web searches peaked at 50 in January, February, March, August, and October, while dipping to a low of 20 in September. The most notable drop occurred in July, where web searches decreased to 30. This pattern suggests a seasonal variation, with peaks typically occurring in the months traditionally associated with construction activities and building renovations.

The detailed examination of the web search volume trends for "tiling lath" highlights the impact of seasonal demand on this keyword. The peaks during early and mid-year suggest increased interest during optimal construction periods, while the valleys, particularly in late summer and early autumn, could indicate a slowdown in building activities or a shift in focus towards other materials or projects. This analysis underscores the importance of understanding seasonal trends in the construction industry to anticipate changes in search behavior related to construction and building machinery.