(118 products available)

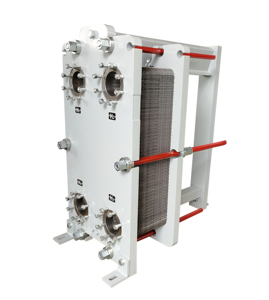

Titanium heat exchangers are critical components designed to transfer thermal energy between two mediums without mingling them. They are specifically crafted to resist corroding environments, which makes titanium an attractive choice for heat exchangers. The working principle of titanium heat exchangers is based on the manufacturer fabricating plates or tubes out of titanium. These plates or tubes are used to create channels. The channels are then used to route the two fluids. As the fluids flow through their respective channels, they come close to each other without mixing. Heat is thus transferred from one fluid to another. Titanium heat exchangers can further be divided into three categories:

Specifications of titanium heat exchanger freon waters are varied according to different applications. The following are some common specifications.

Maintenance requirements of titanium heat exchangers are usually as follows:

Business buyers in diverse fields can leverage the versatile uses of titanium heat exchangers.

Air conditioning and refrigeration:

Titanium heat exchanger freon waters sits well in air conditioning systems intended for cool winters and warm summers. They help remove heat from the refrigerant so that it can get rid of heat from the indoor or enclosed spaces. Also, titanium heat exchangers are used to cool the refrigerant in commercial refrigeration systems, such as walk-in coolers, grocery store freezers, and large-scale fridges and freezers. In these systems, titanium heat exchanger tubes transfer heat from the refrigerant to outside air or water, maintaining a low temperature inside the refrigeration unit to keep food items fresh and prevent them from spoiling.

Marine applications:

Titanium heat exchangers are used in various marine applications, including boat cooling systems, desalinators, and underwater submersibles. In boat cooling systems, titanium freon AC coils are used in the engine's cooling system to remove heat from the engine coolant. Titanium heat exchanger refrigerants also serve as desalination plants, where seawater is heated to evaporate the water and leave behind salt. The purified water is then condensed through a titanium refrigerant heat exchanger, which cools the water by transferring heat to the surrounding environment. Furthermore, titanium heat exchanger steel pipes are used in underwater submersibles to regulate temperature within the vessel, maintaining comfort for crew members and the integrity of onboard equipment.

Industrial processes:

Many industries, like the chemical, oil and gas, power generation, pulp and paper, and food and beverage industries, use titanium heat exchanger condensers to carry out their operations. In the chemical industry, titanium heat exchangers are fitted into reactors, separators, and dryers, among other units, to facilitate chemical reactions and process materials. Titanium air conditioning coils can be applied in the petroleum industry to refine crude oil and separate natural gas components. Power plants use titanium heat exchanger tubes in steam generators, condensers, and cooling towers to transfer heat. Also, titanium heat exchanger plates serve in the food and beverage industry, where they are used in pasteurizers, sterilizers, and process lines to process, cool, or heat food and beverage items.

When choosing a titanium freon heat exchanger, several factors influence the decision to select an exchanger that suits the application needs and specifications.

Application requirements analysis

To begin with, buyers need to determine the fluids to be used in the heat exchanger and check their temperature and pressure conditions. They should also take note of the allowable size and installation space for the heat exchanger. With this information, buyers can easily decide on the type and design of the heat exchanger that works for their industrial plant.

Hydraulic performance

Next, buyers should consider the hydraulic performance of the titanium freon heat exchanger. It's important to pay attention to flow areas, pressure drops, and hydraulic diameters to ensure that the exchanger can meet the needs of the system in order to avoid the inconvenience of system cooperation later on.

Service and maintenance

It should be easy to clean, inspect, and maintain over the lifespan of the heat exchanger through the selection of titanium heat exchanger Freons for water and also consider the service and maintenance options available. If there are any repair requirements, the heat exchanger should be serviced quickly and conveniently. A good service level will help reduce lifetime costs.

Q1: How long can a titanium heat exchanger last?

A1: The typical lifespan of titanium heat exchangers Freon is about 20 years. However,Heat exchangers can last longer if they are well-maintained and operated under ideal conditions.

Q2: Can users fix a titanium heat exchanger?

A2: Small damages such as hairline cracks and leaks in the titanium heat exchanger can be repaired using a welding technique known as weld overlay. However, if the damage is significant or if the heat exchanger is not functioning effectively, it is better to replace it completely.

Q3: What are the signs that a titanium heat exchanger is bad?

A3: There are several signs that indicate a damaged titanium heat exchanger. They include; a drop in Freon pressure, the presence of air or carbon in the water, overheating of the compressor, or the titanium heat exchanger burner not working. If any of these signs occur, it is better to call an expert to advise on replacing or repairing the unit.

Q4: What happens when a titanium heat exchanger is clogged?

A4: A clogged titanium heat exchanger will impede the flow of water. This blockage will affect heat transfer and cause the unit to overheat. Continuous overheating can cause the compressor to fail and damage other components of the chiller or AC system.