(89093 products available)

To clay machine refers to a set of tools and equipment used to process and prepare clay for pottery making and other ceramic products. There are many types of clay machines, which can be categorized into two main categories: manual and electric.

Manual clay machines

Standing clay templates are generally used in the first type of manual machine. For example, the manual hand roller is a representative of the standing type. It provides a template for a potter to manually use their hands to roll out the clay and create various shapes. In addition, a hand-turned slab roller consists of two parallel rolls separated by an adjustable gap and a flat template. Potters put wet clay between the two rolls to press the clay into thin slabs after turning the roller by hand. Manual slab rollers like these require less effort and skill than other manual techniques.

Electric clay machines

Electric roller tables are popular options for commercial pottery studios and educational institutions because they provide a streamlined production process. An electric roller has a wheel powered by an electric motor that revolves around the table, along with a slab of loosely covered fabric. Potters can use the roller to help shape and mold clay into different pottery pieces. Whether for functional or decorative use, electric rollers offer efficient and precise options for pottery-making.

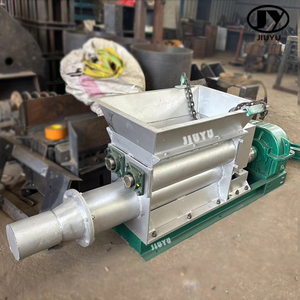

Another type of electric machine is an extrusion table. The extrusion process uses a screw or piston to force soft clay through a shaped die or opening. The extruder has a vertical column or barrel made of metal or plastic that contains a moving part. Potters can then cut the extruded clay into specific lengths and shapes, which is a great way to quickly create pottery pieces. Moreover, wheel-thrown electric clay machines are the most popular pottery-making machines. With the help of an electric motor, the machine rotates at high speed around the center, while potters sit on top and shape clay into various pottery products with both hands. After being completed, the ceramic works will be very smooth. Additionally, the entire process will be much easier and faster.

Using a clay machine has several creative usage scenarios for ceramic artists, hobbyists, and professionals.

When purchasing a clay-making machine, buyers should look beyond aesthetics and consider attributes that will improve their pottery-making experience. The types of machine work and what business buyers want in terms of volume and variety should be the primary considerations when choosing a machine.

For a diverse pottery production line, an all-in-one clay machine is ideal, as it incorporates various functions into one unit. Clay preparation machines, on the other hand, are standalone units that also prepare clay for use in other pottery-making processes. If what one needs is a machine that only extrudes clay, an extrusion machine is preferable. Jiggering and jogging machines shape pottery by either rotating the clay around a stationary form or moving the clay between two heated platens. Both types of machines are better suited for shaping symmetrical pottery or ceramic pieces.

How the clay is fed into the machine should also be a consideration, as the weighing and processing of the clay in different machines vary. Consider whether the machine is operated manually, electrically, or hydraulically, and ensure that the operating system is well-suited to the primary expertise of the staff working at the particular pottery workshop.

In addition to the above methods of categorization, buyers can also choose based on the size and weight of the machine, as well as its capacity and speed. Whether a compact, bench-top model or a large, industrial-sized machine is required will depend on measuring the available space in the workshop. The capacity and speed of the machine will also differ according to the specific type, and these measurements must be aligned with the estimated output needed each month to fulfill customer demands. Precision and consistency are two essential attributes buyers should look for. The ease of adjustment and adaptability of the machine should also be considered, as this will ensure that it can skillfully cater to a range of clay types and pottery designs.

Finally, business buyers should not undermine the importance of easy-to-understand operation and comfortable maintenance. A clearly illustrated user manual and well-defined maintenance schedules will ease the staff's familiarity with and maintenance of the machine. Security and safety features should also be considered, as these will help to reduce the risk of accidents and potential injuries. Warranty, certification, and documentation should all be carefully vetted, even if the machine is small and low in value.

Q1: How did the first clay-making machine work?

A1: The first machine used a simple belt-driven system to wedge, roll, and cut clay. It did not have the efficiency or automation of modern machines.

Q2: What is the impact of the clay machine on the environment ?

A2: Clay machines reduce environmental impacts by using recycled clay and improving material utilization. However, energy use and emissions from larger machines remain concerns.

Q3: What is the trend in clay machine technology?

A3: The trend is toward more automated, computer-controlled machines that integrate entire production lines from clay preparation to shaping, drying, and firing.

Q4: Are there machines for specific types of clay?

A4: Yes, there are specialized machines optimized for working with particular clay bodies, such as lightweight insulation clays, refractories, ceramics, etc.

Q5: What is the future of clay-making machines?

A5: The future lies in smarter machines with AI, higher energy efficiency, zero waste, and more skilled laborer training programs to strengthen the human-machine relationship.