(5222 products available)

Tool holders are crucial parts of CNC (computer numerical control) machines designed to hold cutting tools. The

tool holder has an internal taper that evenly fits the external taper of the spindle, with both having matching angles and grooves to enhance grip and precise alignment.

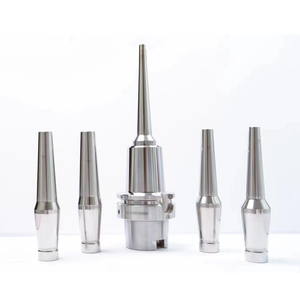

BT30 tool holders

are used in CNC equipment to support and hold various tools, especially in milling operations. They have a small tapers holder that provides a good balance and works well for lighter-duty machining.Things to consider when choosing a BT30 tool holder include the hardness, clamping force, which is reliable, static precision, dynamic precision, working environment, temperature, vibration, floating, dust, moisture, humidity, and voltage.

Common types of BT30 tool holders include:

End Mill Holders

Tool Holders with Presetters

An end mill holder specifically secures an end mill cutter in place. It provides higher accuracy and better grinding rounding than ordinary tool holders to enhance the holding ability. End mill holders can also adapt to cutting tools such as counterbore cutting tools and reamers.

The tool preset holder is designed to preset the tool's length before executing a machining operation. This enables the user to minimize machine downtime and maximize efficiency.

Adapter holders or sleeves are used to convert between fitments, for example, to allow an SK tool to be used with a BT spindle.

The tool holder has a specific maximum weight it can support, which depends on the tool length. The maximum tool holder weight can be calculated by a formula: Maximum weight = (Maximum RPM)/(Tool Length). The tool holder will have some unique specifications that are kind of universal for these types of tool holders:

Dimensions and Capacity

The tool holders will have dimensions and capacity unique to them. Each tool holder was designed for various cutting tools that it should hold. These dimensions will also differ from each taper holder. For instance, the BT30 tool holder can hold a tool with a maximum diameter of 25 millimeters.

Retention Knobs

The retention knobs are used to secure the cutting tool in place. These knobs can vary in height. The retention pin has an industry-standard height of 0.200 inches, but other heights can be custom ordered.

Cooling Through

Some tool holders have passages for coolant to circulate while machining. This passage is also referred to as a "through" and can be included or not, depending on the specific tool holder.

Socket Drive

Like retention knobs, the socket drives can differ from one tool holder to another. Socket drives are the locations where the set screw of the cutting tool will reside. It is usually spherical or dimpled and is designed to securely hold the cutting tool in place.

Taper Size

As mentioned earlier, taper sizes are unique to each tool holder. The taper sizes are integral in ensuring that the tool holder fits correctly in the spindle. The BT30 has a taper size of 7:24 per inch.

Like all machining tools and parts, proper care and maintenance are required to protect the BT30 tool holder from damage and ensure its longevity. Tool holders will usually be removed from the machine and cleaned after cutting. Following this process, the following steps can be taken to protect the tool holder:

Store the tool holder in an appropriate tool holder rack or cabinet when dry. Make sure that none of the tool holders touches each other. It is always better to protect the holders when they are not in use.

Any dirt buildup can be removed by soaking it in a mixture of vinegar, hydrochloric acid, and water in a 1:1:1 ratio. Other than this, a mixture of vinegar and baking soda will also work. Using any other unapproved solution may damage the tool holder.

Ensure tool holders are regularly inspected for cracks or damage. If any is found, the tool holder should be repaired immediately.

Usually common in CNC machines and bits, the BT30 tool holder is used in many industries.

Metalworking Industry

Metalworking refers to industries that make products directly from metals. Such industries use CNC machining centers that require BT30 tool holder attachments. The machining centers cut and shape metal into diverse forms.

Manufacturing Sector

The manufacturing sector involves many industries that make various products. Many of them use CNC machines for precision, automation, and efficiency. As mentioned earlier, BT30 attachments are great for achieving these three qualities. They are commonly used in the metallurgical and woodworking industries.

Aerospace and Automotive Industries

Automotive and aerospace industries often use BT30 tool holder attachments for CNC machining centers. Such machining centers cut and shape metal with extreme precision. They create parts that make cars, airplanes, and satellites.

Woodworking and Construction

A BT30 tool holder is great for more than just metal. It's also perfect for woodworking materials like laminate, composites, and MDF. This makes it an excellent accessory for CNC routers used in the carpentry business. These machines need to precisely cut and shape furniture components, molds, floors, and cabinetry. In the construction industry, they are used for custom architectural details, cabinetry, and furniture pieces, as well as CNC machines to make construction molds.

When choosing BT30 tool holders, buyers need to consider some specific aspects to ensure the holders will meet their needs.

Grippers'

First, buyers need to choose the type of gripper for their tooling system. The gripper is the part of the holder that grips the tool. There are two main types of grippers: internal and external. Internal grippers grip the tool from the inside, while external grippers clamp the tool from the outside. External grippers generally provide more holding power than internal ones. However, internal grippers are more compact and can hold tools with a tighter radius.

Different types of holders require different kinds of grippers. For example, tool holders that use pneumatic or hydraulic clamping systems will require specific grippers compatible with those systems.

Material

Tool holders are commonly made of steel. There are two main kinds of steel used in tool holders: alloy and carbon. Carbon steel is more durable than carbon steel, so it is the more common material. It's also a little lighter. Alloy steel is stronger and heavier. Choose the steel holder depending on the working environment of the machine and the weight needed.

Machine compatibility

Different machines may require specific tool holders to fit their spindles. Ensure the BT30 tool holder is suitable for the intended machine.

Tool compatibility

Different tools may require specific tool holders to fit their shapes and sizes. Some tools, like face mills, require holders with more mass to dampen vibrations. Others, like end mills, can use lighter holders. Also, certain tools have unique shank configurations that may need special adapters or holders.

Balance requirements

It is crucial to consider the balance requirements of the tool in use. High-speed CNC machines usually run at high RPMs. Unbalanced holders can create excessive vibration causing damage to the machine and the holder. They can also reduce the tool's cutting efficiency. For this reason, choosing a holder that matches the balance requirements of the tool is a good idea. For example, some tools require semi-precision, and others require precision balance holders.

Q1: Do tool holders have a standard?

A1: Yes, tool holders have a standard. The most commonly used standards are the CAT, ISO, BT, and HSKat, which are often used in various CNC machining equipment.

Q2: What is the function of the tool holder?

A2: The tool holder has a few functions, such as supporting the cutting tools, clamping the tools firmly in place, maintaining the alignment of the tool during operation, and absorbing shock and vibration generated during the cutting process.

Q3: What is the difference between BT30 and BT40 tool holders?

A3: The BT30 tool holder has an advantageous compact lightweight design that helps to reduce vibration during the machining process, thereby improving accuracy and surface finishing. On the contrary, BT40 tool holders are more solid and widely used in heavy-duty machining situations. They are suitable for handling larger workpieces and more complex machining tasks.