(2871 products available)

Usually, a tools holder HSK is a short form of the high-speed steel tools holder, which is a renowned tool holder of machine tools. Tool holders are significant parts of machinery that help to hold the tool in place. Several types of tool holders are available on the market.

Universal tool holders can be used to hold any insert geometry, as long as it has been of an indexed insert. This can be a great advantage and often offers a much lower initial cost. However, the universal toolholder's adjustability might result in less than optimal.

Also regarded as specialized tool holders, specific tool holders are designed to hold a specific insert geometry. In addition to that, they also cater to a particular application requirement. While specific tool holders may offer a perfect fit and enhanced performance, they can come at a higher cost and may limit versatility.

There are many tool holder standards, like the double-contact taper (CT), which are prevalent in high-end machining centers. Other prevalent standards are the HSK (Hohl-Schnecken-Kupplung or Hollow Hill Screw Coupling), which are renowned for their high stiffness and precision alignment. Also, the SK tapers are pretty popular in vertical mills, while the MK is also known as the Morse taper machine. The BT is mostly used in bridge saw machines. Depending upon the need, working requirement, and project, buyers can choose any of the above-mentioned standards.

Tools holder HSK comes with technology-specific specifications based on different needs in the industry. The following are standard specifications buyers should know when buying these tool holders.

Tapert Diameter

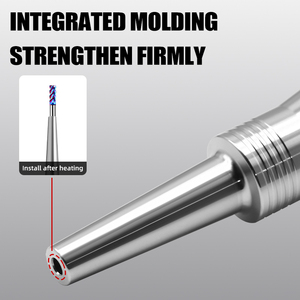

Like most tool holders, HSs holders come with an HSK taper characterized by a specific taper diameter. The taper diameter affects the grip strength of the tool. A tool holder with a larger taper diameter will offer better stability and clamping force.

Length

HSK tool holders have various lengths. Shorter holders are more common and suitable for jobs that require high-speed machining. Longer holders provide more clearance, and they are suitable for deep-cutting applications.

Maximum RPM

The maximum revolutions per minute of an HSK tool holder determines its machining capability. This is the speed at which the tool holder rotates. HSK tool holders with a higher RPM are suitable for high-speed machining operations.

Weight

HSK tool holders are generally lightweight, which is a feature that improves overall machine performance. However, the weight varies depending on the length and size. Machines that require high-speed cuts and lower centrifugal forces prefer lighter tool holders.

Proper maintenance of tools holders increases their lifespan and ensures optimum performance. The following are some practical maintenance tips for HSK tool holders.

The tool holder is extremely useful and helpful for various equipment and machines all around the industrial sector.

CNC machines:

An HSK tool holder is frequently used in CNC machines to hold cutting tools such as saw blades for precise machining operations. The HSK's quick-release mechanism allows for smooth tool changes and increased production efficiency, as multiple tools can be quickly swapped out to adapt to different machining tasks without stopping the CNC machine for extended periods. This helps to reduce downtime and increase overall productivity on the CNC machining floor.

Automotive Industry:

In the automotive industry, an HSK tool holder can be used in robotic arms for assembly or welding tasks. The precise control and repeatability of the HSK tool holder enable accurate positioning and smooth operation of robotic arms when handling automotive components, resulting in high-quality automotive products.

Medical Device Manufacturing:

Medical device manufacturing requires high-precision machining of small, complex parts. HSK tool holders are commonly used in CNC machines and micro-milling machines for medical device production because of their ability to maintain tool stability and precision.

Aerospace industry:

In the aerospace industry, precise machining of complex components is critical. High-speed spindles used in precision machining centers and HSK tool holders are commonly used for cutting tools. HSK tool holders have a quick-change feature that allows for smooth transition between different cutting tools, increasing productivity and efficiency.

Woodworking:

In the woodworking industry, the woodworking industry often needs to perform complex machining operations such as cutting, drilling, and milling on different types of wood materials. High-speed spindles are commonly used in woodworking machining centers and CNC machines for woodworking. An HSK tool holder can be used to hold cutting tools such as saw blades and drill bits. The high-speed rotation capability of HSK tool holders allows for efficient and precise machining of wood.

Plastic Products:

In the plastic product manufacturing industry, precision machining of plastic materials is required to produce high-quality plastic products. An HSK tool holder can be used in CNC machines or machining centers to hold cutting tools for milling and drilling. The tool change speed and accuracy of HSK tool holders meet the production needs of plastic products.

Tools holders are essential parts of CNC machines. They ensure that the tool is held firmly and effectively, which helps to carry out the machining operation perfectly. However, when choosing the suitable tools holders for the machine tool, first, know the kind of tasks the machine will perform and its spindle connection type. This section will discuss the things one is likely to come across when choosing the tools holder.

Q1. What is the difference between HSK and BT tool holders?

A1. The HSK tool holder has an inner taper with axial draw, allowing higher rotational speeds and reduces the risk of slippage in the tool holder. On the other hand, BT tool holders taper externally and rely on friction and gravity to maintain the position. HSK tool holders are more commonly used in high-speed applications, while BT tool holders are used in various milling machines.

Q2. Is tool holder HSK standardized?

A2. Yes, the standardized HSK tool holders increase interchangeability between tools, holders, and spindles from different manufacturers.

Q3. How does tool holder HSK improve machining efficiency?

A3. HSK tool holders improve machining efficiency by providing a secure and rigid tool holder system. Their unique taper and locking mechanism minimize tool chatter, enhance cutting performance, improve spindle utilization, and increase feed rates.

Q4. Can HSK tool holders be used with Cat and Bt holders?

A4. It is not recommended because HSK tool holders are designed for high-performance machining. When using them with machines not designed for HSK tool holders, their benefits may be reduced.