(532 products available)

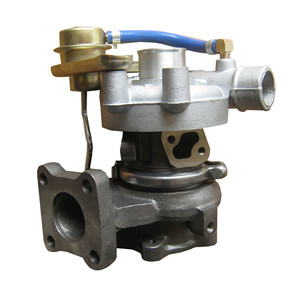

It's safe to say that no one wants to drive a sluggish car. As a result, the automotive industry has come up with ways to maximize engine efficiency and power. One of the most popular methods is using CT9 turbocahrgers. The device forces more air into the engine to produce more power. While there are several types of turbochargers, CT9 turbochargers stand out when it comes to car models like Lexus, Toyota, and Subaru. So, what are the different types of CT9 turbos?

Toyota CT9 turbocharger

Generally, Toyota CT9 turbochargers are designed for specific models like the Toyota Land Cruiser 2.8D 1KZ-TE, Toyota Hilux Surf 2.8D 1KZ-TE, and Toyota Previa 2.4D 3CT-TE. However, they are also further divided into different types based on the model. For instance, the Toyota CT9 turbo for the Toyota Land Cruiser is known as CT9A/CT9B turbo. The CT9A/CT9B turbo is further divided into two main categories; the Normal turbo and the High-Performance turbo. The Normal CT9A/CT9B turbo has a modest boost pressure and is designed to be a direct replacement for the existing turbo. On the other hand, the High-Performance CT9A/CT9B turbo is modified to increase airflow and boost pressure. As a result, it delivers a more significant power increase when compared to the Normal CT9A and CT9B turbos.

K03 and K03-029 turbos

The CT9 turbochargers are also known as KO3 and KO3-029 turbochargargers. The K03 turbo is the standard turbo for most vehicles. It is efficient but has a limited power ceiling. On the other hand, the K03-029 turbo is an upgraded version. The K03-029 turbo has a larger compressor wheel and housing, allowing it to generate more boost and power.

Overall, CT9 turbocahrgers are compresed air manufacturers with different types suitable for various applications. They are also further divided into different models, each with unique features to meet specific needs.

Specifications of CT9 Turbos are as follows:

Compressor wheel:

The compressor wheel is the heart of the CT9 turbo. It is usually constructed of aluminum and has a diameter of 42-46 mm. The compressor wheel's function is to increase airflow into the engine, therefore increasing horsepower and torque. The compressor wheel is also designed to be lightweight so that it can spin faster and provide boost pressure more quickly.

Turbine wheel:

The turbine wheel drives the turbine shaft and is usually constructed of high-strength stainless steel. The turbine wheel has a diameter of 40-44 mm. The turbine wheel's function is to exhaust airflow out of the turbo, which helps to drive the turbine and create boost pressure.

Turbocharger housing:

The turbocharger housing consists of the compressor housing and turbine housing. These housings are responsible for directing airflow in and out of the turbo. The compressor housing is typically made of aluminum, while the turbine housing is made of high-strength stainless steel. The housing also contains vanes that help to guide airflow and increase efficiency.

Bearing system:

The bearing system supports the turbine and compressor wheels, allowing them to spin smoothly. The CT9 turbo uses a journal bearing system, which is common in many turbochargers. This system consists of two bearings that support the shaft between the wheels. The bearings are lubricated with engine oil, allowing for smooth operation.

Oil feed and drain lines:

The oil feed and drain lines are responsible for delivering oil to the turbo and draining excess oil away. These lines are critical for lubrication and cooling of the turbo, ensuring optimal performance. The oil feed and drain lines are typically made of high-strength rubber and steel to withstand the high temperatures and pressures of the turbocharger system.

CT9 turbos must be maintained regularly for optimal performance. Here are a few maintenance tips:

Choosing the right CT9 turbo for a vehicle can be a complex process. It's important to consider several factors to ensure the turbo meets the specific needs and expectations for performance and reliability.

Understand the Engine:

One should comprehend the current engine setup, including its displacement, configuration, and any existing modifications. This understanding is essential because different engines respond differently to turbocharging.

Determine Performance Goals:

Consider what performance improvements are desired. Is there a need for more low-end torque for towing, or is the focus more on high-end power for track performance? Different CT9 turbos excel in varying areas.

Research Turbo Specifications:

Turbos CT9 come with different specifications, including turbine and compressor wheel sizes. Research these details and understand how they impact engine performance. A larger turbine might provide more top-end power but could result in turbo lag.

Quality and Reliability:

It's crucial to select a reputable supplier for turbos CT9 to ensure the quality and reliability of the turbo. Chovm.com offers various suppliers with customer reviews that can assist in determining the reliability of the supplier.

Consider Installation and Compatibility:

Ensure the chosen turbo is compatible with the current engine and exhaust system. Also, consider the complexity of the installation process and whether any additional components or modifications are required.

Budget:

Establish a budget for the turbo purchase and any necessary supporting components, such as intercoolers, exhaust systems, or engine management systems. Sometimes, spending a little more for a turbo with the desired specifications can be more cost-effective than settling for a cheaper, less suitable option.

Replacing a Turbo CT9 is not a simple task. It requires attention, knowledge, and mechanical skills. Here is a step-by-step guide on how to replace Turbo CT9:

Tools Needed

Step-by-Step Guide

Prepare the Vehicle

Park the vehicle on a level surface. Set the parking brake and disconnect the negative battery cable. Use the jack and jack stands to raise the vehicle and secure it.

Drain Fluids

Place an oil drain pan under the turbocharger to drain the oil. Drain the coolant from the cooling system.

Remove the Exhaust Downpipe

Use a socket set to remove the bolts connecting the exhaust downpipe to the turbo. Carefully lower the downpipe.

Remove the Intake Pipe

Use a wrench set to remove the bolts securing the intake pipe to the turbo. Disconnect the pipe from the turbo.

Disconnect the Oil Lines

Use a wrench set to remove the oil lines connected to the turbo. Be prepared for oil spills and drain the oil lines into the oil drain pan.

Remove the Coolant Lines

Disconnect the coolant lines connected to the turbo. Drain any coolant from the lines.

Remove the Wastegate Actuator

Use a socket set to remove the wastegate actuator from the turbo. Disconnect the actuator from the turbo.

Remove the Turbocharger Bolts

Use a socket set to remove the bolts securing the turbo to the exhaust manifold. Carefully slide the turbo out of the engine bay.

Install the New Turbo

Position the new turbo onto the exhaust manifold and tighten the bolts. Reconnect the wastegate actuator, oil lines, coolant lines, intake pipe, and exhaust downpipe. Ensure all connections are secure and leak-free.

Refill Fluids

Refill the engine oil and coolant. Start the engine and let it run for a few minutes. Check for any leaks or unusual noises.

Q1: What is the CT9 turbo?

A1: The CT9 turbo is a factory turbo used in most 1.0L 3-cylinder petrol engines from the Toyota group.

Q2: What is the common problem with the CT9 turbo?

A2: The CT9 turbo has several common problems. However, turbo failure is the most reported issue. This problem arises due to wear and tear, which is mostly caused by neglecting regular oil changes and low oil levels.

Q3: How long does a CT9 turbo last?

A3: A CT9 turbo can last up to 200,000 miles. However, this mileage can be affected by several factors. For instance, driving habits, oil quality, and poor maintenance can cause the turbo to fail prematurely.