(41338 products available)

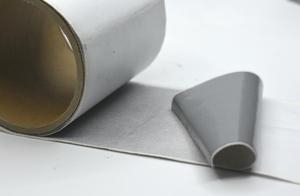

Waterproof roofing membranes are thin, continuous sheets primarily designed for waterproofing. They are used in various construction applications, especially for roofs. Membranes are made from different materials; some require adhesives for application, while others are self-adhesive or can be applied using heat. Below are the different types of waterproof roofing membranes:

Bitumen-Based Membranes

Bitumen-based membranes are the most popular waterproof roofing membranes. They are used on flat roofs and consist of a base layer of fiberglass or polyester felt saturated with hot or cold asphalt. The top layer is usually modified bitumen, which is either APP (atactic polypropylene) or SBS (styrene-butadiene-styrene). APP is a thermoplastic that becomes soft when heat is applied, while SBS is a rubber-like thermoplastic. These membranes are durable, economical, and effective in waterproofing.

EPDM Rubber Membranes

EPDM rubber membranes are made from synthetic rubber and are mainly used for flat roofs. They are known for their exceptional durability and resistance to UV radiation, extreme temperatures, and ozone. These membranes are usually black but can be white to reflect heat. EPDM membranes are easy to install, requiring only a few basic tools, and are often glued down or held in place by weights.

TPO Membranes

TPO (Thermoplastic Olefin) membranes are also used on flat roofs. They are made from a blend of polypropylene and rubber, providing excellent UV resistance, heat reflectivity, and waterproofing. These membranes are usually white and can be mechanically fastened, glued, or heat-welded. They are popular in commercial roofing due to their energy efficiency and cost-effectiveness.

PVC Roofing Membranes

PVC membranes are thermoplastic and consist of a plastic matrix reinforced with polyester. They have a layer of liquid plastic containing halogenated flame retardants. The top layer is made of UV inhibitors and pigments, usually black or white. PVC membranes are popular in commercial applications because they are lightweight, durable, and recyclable. They resist chemicals, water, and fire, making them ideal for restaurant and industrial facility roofs.

Modified Bitumen Membranes

These membranes combine the durability of bitumen with the elasticity of rubber. They are modified with a polymer, making them more resistant to temperature changes. Modified bitumen membranes are installed using torch application, peel-and-stick, or hot asphalt. They are popular for residential flat roofs.

Liquid Applied Membranes

Liquid-applied membranes are different from other membranes because they do not come in sheets. Instead, they are applied as liquids that harden into a seamless membrane. They are made from polyurethane or silicone. Liquid applied membranes are more versatile, ideal for irregularly shaped roofs, and create a strong, adhesive bond with the substrate. They also resist UV degradation and ponding water.

Prevent water from coming in:

Waterproof membranes keep water from leaking into the building through the roof. This protects the roof and the entire building.

Control water vapor:

Some membranes allow water vapor to escape. This helps prevent condensation buildup inside the roof. Controlling moisture keeps the roof healthy.

Cover different materials:

Membranes come in various materials, like rubber, plastic, asphalt, or modified bitumen. Each type works well for specific roof needs.

Adapt to different temperatures:

Some membranes remain flexible when it's cold outside. Others don't get soft when it's hot. This flexibility prevents issues as the roof material expands and contracts with the temperature changes.

Protection from the sun:

Certain membranes reflect the sun's heat and light away. This helps keep the building cooler and protects the roof from sun damage over time.

Simple to install:

Many waterproof membranes are easy to put on the roof. They can be rolled out and stuck on without complicated procedures. This makes installation faster and saves money.

Long-lasting and strong:

Once installed, these membranes can last many years—proofing them against holes, rips, or leaks. They keep the roof safe for a long time.

Easy to repair:

If the membrane ever gets damaged, it is usually simple to fix. Patching holes or tears only takes a short time so that the roof stays protected.

Reduce noise and heat:

Some membranes help cut down outside sounds that come through the roof. Others help keep the building cooler by blocking the sun's heat from above.

Environmentally friendly options:

There are membranes made with recyclable materials or that help the roof qualify for green building ratings. These eco-friendly choices appeal to companies wanting less impact on the planet.

Waterproof roofing membranes are versatile and widely applicable in the construction and infrastructure industry. Here are some common usage scenarios:

Commercial Buildings

Waterproof roofing membranes are widely used on flat or low-slope roofs in commercial buildings such as office complexes, shopping malls, hospitals, and hotels. The membranes provide effective moisture management, protecting the building from water infiltration and extending the longevity of the roofing system.

Residential Homes

Many residential homes use waterproof roofing membranes in both steep-sloped and low-slope roofs. The membranes act as a water barrier, preventing leaks caused by heavy rain, snow, or ice dams. This helps safeguard the roof structure, insulation, and interior spaces.

Parking Garages

Waterproof membranes are commonly used to cover the roofs of parking garages. The membranes protect the garage structure from water damage caused by rain, melting snow, and ice. This reduces maintenance costs and increases the lifespan of the parking garage.

Balconies and Terraces

Balconies and terraces often serve as outdoor living spaces. Waterproof roofing membranes provide a durable and reliable waterproofing solution to prevent water infiltration into the building envelope.

Green Roofs

Green roofs use waterproof roofing membranes to manage water effectively. The membranes prevent water infiltration into the roof structure, ensuring the longevity of the roofing system. They also support sustainable building practices by reducing stormwater runoff and improving energy efficiency.

Industrial Facilities

Waterproof membranes are used in industrial facilities like factories, warehouses, and manufacturing plants. The membranes protect the building from water damage, ensuring the safety of operations, equipment, and stored materials.

Hospital and Healthcare Facilities

Waterproof membranes are important in healthcare facilities to prevent water infiltration. This is important in maintaining a clean and safe environment for patients, staff, and medical equipment.

Data Centers

Data centers rely on waterproof roofing membranes to prevent water infiltration. This protects sensitive equipment and ensures uninterrupted operations. The membranes also help maintain optimal temperature and humidity levels within the data center.

Sports Facilities

Waterproof membranes are used in sports facilities like stadiums, arenas, and gymnasiums. The membranes protect the building from water damage and ensure the safety of athletes, spectators, and staff.

Cost of waterproof membrane for roof

EPDM is among the most cost-effective membranes, while PVC is on the higher end. However, it is crucial to evaluate the long-term advantages versus the initial investment. High-quality membranes often deliver superior durability and lower maintenance costs over time.

Durability and climate suitability

This should be the primary factor when choosing a membrane. Consider the local climate conditions and temperature range. For warmer climates, PVC may be better due to its UV resistance. In contrast, EPDM is ideal for cooler regions as it performs well under varying temperatures.

The roof's characteristics also matter. TPO is suitable for most flat roofs, while PVC excels on roofs with high foot traffic. Membrane durability is vital. High-quality membranes last 25 to 30 years, offering long-term protection.

Installation and maintenance

Ease of installation: Some membranes, like TPO, are straightforward to install, reducing labor costs. Others, such as PVC, require skilled labor but provide better long-term results.

Maintenance requirements: Consider the long-term maintenance needs of each membrane type. EPDM requires less maintenance once installed, while TPO may need more skilled labor for repairs.

Aesthetic considerations

Color options: Most membranes are black on the outside for heat absorption. However, white TPO and PVC membranes are available for UV protection.

Design integration: Ensure the chosen membrane fits the building's design and does not compromise aesthetics.

Environmental impact

Recyclability: Opt for membranes that are partially or fully recyclable at the end of their lifespan, such as PVC and TPO. This reduces environmental impact.

Material sustainability: Choose membranes with sustainable materials. For instance, TPO is made from less oil than others, making it more sustainable.

Q1: What are the common types of waterproof roofing membranes?

A1: There are several types of waterproof roofing membranes, including; thermoplastic polyolefin (TPO), ethylene propylene diene monomer (EPDM), thermoplastic polyvinyl chloride (PVC), modified bitumen, built-up roofing (BUR), and liquid-applied membranes.

Q2: What are the waterproofing membranes for roofs called?

A2: Waterproof membranes for roofs are commonly referred to as roofing membranes. They are essential components in flat or low-sloped roofs, providing waterproofing protection and contributing to energy efficiency and structural integrity.

Q3: What is a waterproof roofing membrane?

A3: A waterproof roofing membrane is a thin layer of material applied to the roof surface. It is designed to prevent water from penetrating the roof. Waterproof membranes protect the roof from water damage, leaks, and other related issues.

Q4: Do waterproof roofing membranes work?

A4: Yes, waterproof membranes work effectively. They help in preventing water damage by creating a barrier that stops water from seeping through the roof. However, proper installation and maintenance are crucial for their long-term effectiveness.

Q5: What is the difference between a waterproof and a water-resistant membrane?

A5: Waterproof membranes are designed to prevent water from passing through, even under high pressure. In contrast, water-resistant membranes can stop water from passing through under low or medium pressure. Essentially, waterproofing offers a higher level of protection than water-resistant.