Types of Zongshen 150cc Engines

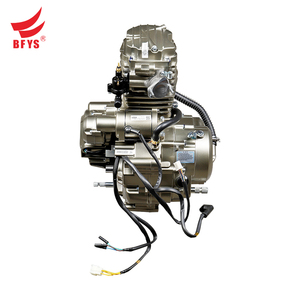

The Zongshen 150cc engine is a popular choice for motorcycles and other small vehicles due to its fuel efficiency, low emissions, and reliable performance. These engines come in different variants to suit various applications and performance requirements.

Water-Cooled Engine

The Zongshen water-cooled engine features an advanced cooling system that uses liquid to regulate engine temperature, providing several key benefits:

- Superior temperature regulation

- Enhanced performance during high-speed operation

- Improved engine efficiency

- Reduced wear and tear

- Quieter operation

Best for: High-performance motorcycles and vehicles requiring stable power output during extended use or high-speed operations

Air-Cooled Engine

The Zongshen air-cooled engine relies on air circulation to dissipate heat, offering its own set of advantages:

- Simpler structural design

- Lower maintenance requirements

- More affordable price point

- Lighter weight

- Easier to repair

Best for: Daily commuters, recreational riders, and applications where simplicity and reliability are prioritized over maximum performance

Expert Tip: If you primarily ride in hot climates or frequently operate your motorcycle at high speeds, consider investing in a water-cooled Zongshen engine for better thermal management and engine longevity.

| Feature | Water-Cooled Engine | Air-Cooled Engine |

|---|---|---|

| Cooling Method | Liquid circulation system | Air flow around engine fins |

| Temperature Stability | Excellent | Good |

| Maintenance Complexity | Higher | Lower |

| Weight | Heavier | Lighter |

| Cost | Higher | Lower |

| Ideal Usage | Performance riding, extended operation | City commuting, casual riding |

Specifications and Technical Details

The Zongshen 150cc engine is a robust four-stroke power unit primarily designed for motorcycles. Understanding its technical specifications is essential for proper operation, maintenance, and performance expectations.

| Specification | Details | Notes |

|---|---|---|

| Engine Type | Four-stroke, single cylinder | Provides balance between power and fuel economy |

| Displacement | 149.5ml (cc) | Standard 150cc class designation |

| Maximum Power | 9.5kW at 8000rpm | Suitable for various motorcycle applications |

| Maximum Torque | 11.5N·m at 6500rpm | Provides good low-end acceleration |

| Bore × Stroke | 57.0mm × 58.6mm | Slightly under-square design for better torque |

| Compression Ratio | 9.0:1 | Balanced for regular fuel usage |

| Ignition System | Transistorized (CDI) | Reliable electronic ignition |

| Starting System | Electric and kick start | Dual starting options for convenience |

| Lubrication | Pressure and splash | Combined system for thorough component protection |

| Valve System | SOHC, 2 valves per cylinder | Simpler design focused on reliability |

Performance Curve

Performance Note: The Zongshen 150cc engine delivers its peak torque at a moderate 6500rpm, making it particularly suitable for everyday riding with good acceleration in the mid-range where most street riding occurs. The power band is relatively broad, providing usable power from approximately 4000rpm to 8500rpm.

Maintenance and Care

Proper maintenance is essential for maximizing the lifespan and performance of your Zongshen 150cc engine. Following a regular maintenance schedule will help prevent breakdowns, reduce repair costs, and ensure optimal operation.

Essential Maintenance Schedule

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Engine oil change | Every 1000km or 3 months | Critical |

| Oil filter replacement | Every other oil change | High |

| Air filter cleaning/replacement | Every 2000km or as needed | High |

| Spark plug inspection/replacement | Every 3000km | Medium |

| Valve clearance check | Every 5000km | High |

| Cooling system inspection | Monthly (water-cooled engines) | Critical |

| Battery maintenance | Quarterly | Medium |

| Complete service | Annually or every 10,000km | Critical |

Maintenance Best Practices

-

Follow the service schedule

Adhere to the manufacturer's recommended maintenance intervals. Regular service ensures all engine components are functioning properly and helps identify potential issues before they become serious problems.

-

Use genuine parts

Always use authentic Zongshen replacement parts for repairs and service. Genuine parts are designed specifically for your engine, ensuring proper fit, function, and longevity compared to aftermarket alternatives.

-

Keep the engine clean

Regularly clean the external surfaces of your engine to prevent buildup of dirt, oil, and debris. This not only helps with visual inspections but also prevents contaminants from entering critical components.

-

Use the correct oil

Always use the manufacturer-recommended grade of engine oil (typically 10W-40 for most conditions). Quality oil is crucial for proper lubrication and heat dissipation within the engine.

-

Monitor the cooling system

For water-cooled models, regularly check coolant levels and inspect hoses for leaks or damage. Maintain proper coolant mixture according to climate conditions. For air-cooled models, ensure cooling fins are clean and unobstructed.

-

Maintain the electrical system

Keep battery terminals clean and properly connected. Check wiring for signs of wear or damage, and ensure all electrical components are functioning correctly.

-

Pay attention to tire maintenance

While not directly related to the engine, proper tire maintenance affects overall performance and safety. Check tire pressure regularly and inspect tread condition.

Warning: Never operate a Zongshen 150cc engine with insufficient oil levels or after detecting unusual noises, vibrations, or smoke. Continuing operation under these conditions can result in severe engine damage.

How to Choose Zongshen 150cc Engines

Selecting the right Zongshen 150cc engine requires careful consideration of several key factors to ensure it meets your specific needs and application requirements.

Application Considerations

Different applications demand different engine characteristics:

- Daily commuting: Focus on fuel efficiency and reliability

- Delivery services: Emphasis on torque and durability

- Off-road use: Look for rugged construction and low-end power

- Racing/Performance: Higher compression models with better cooling

Environmental Considerations

Regional regulations and operating conditions affect engine selection:

- Emission standards: Ensure compliance with local regulations

- Climate: Water-cooled for hot regions, air-cooled sufficient for moderate climates

- Altitude: Consider performance impacts at high elevations

- Fuel quality: Higher quality fuels allow for higher compression engines

Key Selection Criteria

| Selection Factor | Considerations | Impact on Decision |

|---|---|---|

| Fuel Efficiency | Operational costs, range requirements | Critical for delivery, commuting, or long-distance applications |

| Maintenance Requirements | Service intervals, part availability, technical complexity | Consider local service capabilities and your mechanical expertise |

| Performance Specifications | Power, torque, acceleration needs | Match to application demands (speed vs. load carrying) |

| Noise and Vibration | Comfort, operational environment restrictions | Important for urban use or noise-sensitive applications |

| Size and Weight | Installation constraints, vehicle weight distribution | Consider frame compatibility and overall weight balance |

| Cost Factors | Initial purchase, parts, maintenance expenses | Balance upfront costs against long-term reliability needs |

| Compatibility | Mounting points, electrical systems, transmission type | Ensure proper integration with existing components |

Buyer's Tip: When comparing Zongshen 150cc engine models, request detailed specification sheets and, if possible, seek testimonials from users in similar applications to yours. Consider the total cost of ownership rather than just the purchase price.

DIY Engine Replacement Guide

Replacing a Zongshen 150cc engine requires mechanical knowledge and appropriate tools, but with careful preparation and attention to detail, it can be accomplished by experienced DIY enthusiasts.

Preparation Steps

Tools Needed

- Socket set (metric)

- Torque wrench

- Screwdriver set

- Pliers and wire cutters

- Engine hoist or lift

- Drain pan

- Safety equipment (gloves, eye protection)

- Manufacturer's service manual

Before You Begin

- Obtain a compatible replacement engine

- Photograph existing connections for reference

- Work in a well-ventilated, clean area

- Disconnect the battery (negative terminal first)

- Allow the engine to cool completely

- Prepare containers for fluids

- Organize a system for keeping track of fasteners

Replacement Process

-

Disassembly Preparation

Remove any body panels, fairings, or covers that might obstruct access to the engine. Document the position of all components before removal to ensure proper reassembly.

-

Disconnect Components

Methodically disconnect all electrical connections (ignition coil, sensors, starter motor), fuel lines, throttle cables, and exhaust system. Label each connection clearly as you proceed.

-

Fluid Drainage

Drain all fluids from the engine including oil and coolant (for water-cooled models). Dispose of these fluids properly according to local regulations.

-

Remove Mounting Hardware

Locate and remove all bolts securing the engine to the frame. Support the engine with a jack or engine hoist before removing the final mounting bolts.

-

Engine Extraction

Carefully lift or lower the engine from the frame, paying attention to clearance issues. This step often requires an assistant to guide the engine and prevent damage to other components.

-

Install New Engine

Position the replacement engine in the frame, aligning all mounting points. Insert mounting bolts hand-tight initially to allow for adjustments.

-

Secure Engine Mounts

Once properly positioned, tighten all engine mounting bolts to the manufacturer's torque specifications in the correct sequence.

-

Reconnect Components

Reconnect all electrical connections, fuel lines, cables, and exhaust components in reverse order of disassembly. Refer to your photos and notes for guidance.

-

Fluid Refill

Add the specified type and amount of engine oil and coolant (if applicable). Check for proper levels according to the owner's manual.

-

Final Inspection

Perform a thorough inspection of all connections, ensuring everything is properly secured and no tools or parts remain in the engine area.

-

Initial Start and Testing

Reconnect the battery, start the engine, and allow it to idle while checking for leaks, unusual noises, or vibrations. Perform a careful test ride after confirming proper operation.

Safety Warning: Engine replacement involves working with heavy components and potentially hazardous fluids. If you're unsure about any step in the process, consult a professional mechanic. Improper installation can lead to serious damage or safety hazards.

Frequently Asked Questions

The cost of a Zongshen 150cc engine typically ranges from $400 to $800 USD, depending on several factors:

- Model specifications: Water-cooled engines generally cost more than air-cooled versions

- Supplier source: Direct factory purchases may offer better pricing than through distributors

- Geographic location: Import duties and shipping costs vary by country

- Quantity ordered: Bulk purchases often qualify for discounts

- New vs. rebuilt: Factory rebuilt engines are available at lower price points

For the best deals, consider checking reputable online marketplaces like Chovm.com where manufacturers often offer competitive pricing and seasonal promotions.

With proper maintenance, a Zongshen 150cc engine typically lasts between 30,000 to 60,000 kilometers (18,000 to 37,000 miles). However, several factors significantly impact longevity:

| Factor | Impact on Lifespan |

|---|---|

| Maintenance frequency | Regular oil changes and servicing can double engine life |

| Operating conditions | Extreme temperatures, dusty environments, and high-altitude operation accelerate wear |

| Riding style | Aggressive acceleration, high-rpm operation, and overloading reduce lifespan |

| Fuel quality | Low-quality fuel introduces contaminants and causes carbon buildup |

| Storage practices | Proper storage during extended non-use periods prevents internal corrosion |

Some commercial users report achieving over 100,000 kilometers with meticulous maintenance regimens, demonstrating the potential durability of these engines when properly cared for.

Yes, Zongshen 150cc engines offer several upgrade possibilities to enhance performance, efficiency, and reliability:

Common Performance Upgrades:

- Cylinder head modifications: Porting and polishing for improved airflow

- Higher compression pistons: For increased power output (requires higher octane fuel)

- Performance camshafts: Alter valve timing for better top-end power

- Larger carburetors or fuel injection: Increase fuel delivery for higher power

- Exhaust system upgrades: Less restrictive designs improve exhaust flow and power

- Air filtration improvements: Better flowing air filters increase airflow while maintaining filtration

For factory-supported upgrades, contact authorized Zongshen dealers who can provide tuning packages that maintain reliability while enhancing performance. Many aftermarket parts are also available through performance specialists.

Upgrade Advice: When modifying your Zongshen engine, consider making incremental changes and testing thoroughly between modifications. This approach helps identify which upgrades provide the best results for your specific application while minimizing the risk of reliability issues.

While generally reliable, Zongshen 150cc engines can develop several common issues, most of which are preventable with proper maintenance:

- Carburetor clogging: Poor fuel quality or extended storage can lead to fuel system blockages

- Valve clearance problems: Inadequate adjustment can cause poor performance and increased wear

- Oil leaks: Typically from gaskets or seals, especially around the cylinder head

- Starting difficulties: Often related to ignition system components or fuel delivery issues

- Cooling system failures: In water-cooled models, issues with the radiator or water pump

Most of these problems can be avoided through regular maintenance and addressing minor issues before they develop into more serious failures.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4